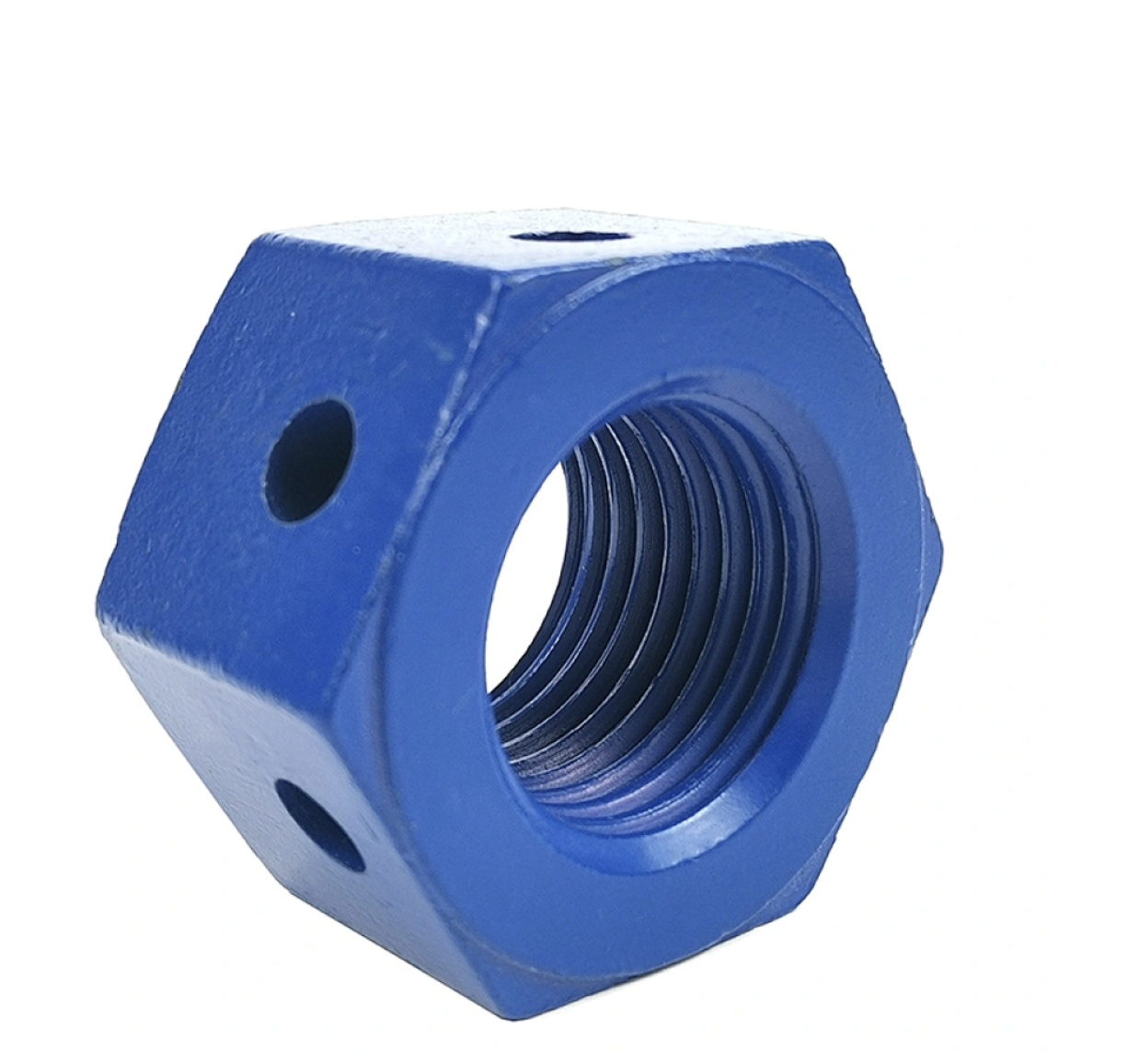

China manufacturer of Stud Bolt with Tommy Bar Hole Nut PTFE Fluorocarbon Coated

What is Tommy Bar Hole?

Hydraulic Bolt Tensioning technology provides the highest level of accuracy, productivity, and safety on critical joints across the energy industry.

Assembly of Hydraulic Bolt Tensioners is started by sliding the hydraulic load cell over the stud bolt until it comes in contact with the flange. The Bolt Tensioner’s puller is then threaded down into each load-cell until securely in contact with the cylinder piston.

Each tensioner is then connected together via hydraulic hoses. You then apply the specified hydraulic pressure, which actuates the hydraulic load-cells and simultaneously places load across the flange by all the interconnected Bolt Tensioners.

Using a tommy-bar you then turn the locking collar on each Bolt Tensioner to place the nut firmly onto the joint surface. Tool pressure is then released and the bolt tensioning procedure is complete.

Tommy Bar Hole Nuts can be supplied for below grade

- Carbon Steel Grades:

- ASTM A563 Grade A, C, and DH.

- Alloy Steel Grades:

- ASTM A194 Grade 2H. Grade 7,Grade 7M

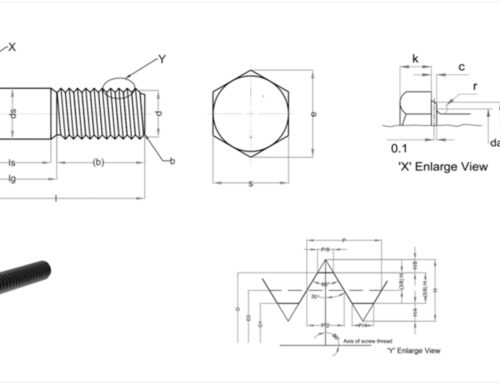

Tommy Bar Hole Nuts Specification

- Size Range:

- Typically available from 1/2 inch (M12) to 2 inches (M48) or more.

- Custom sizes available upon request.

- Thread Standards:

- UNC, UNF, or metric threads (ISO standards).

- Compatibility with matching bolts or studs.

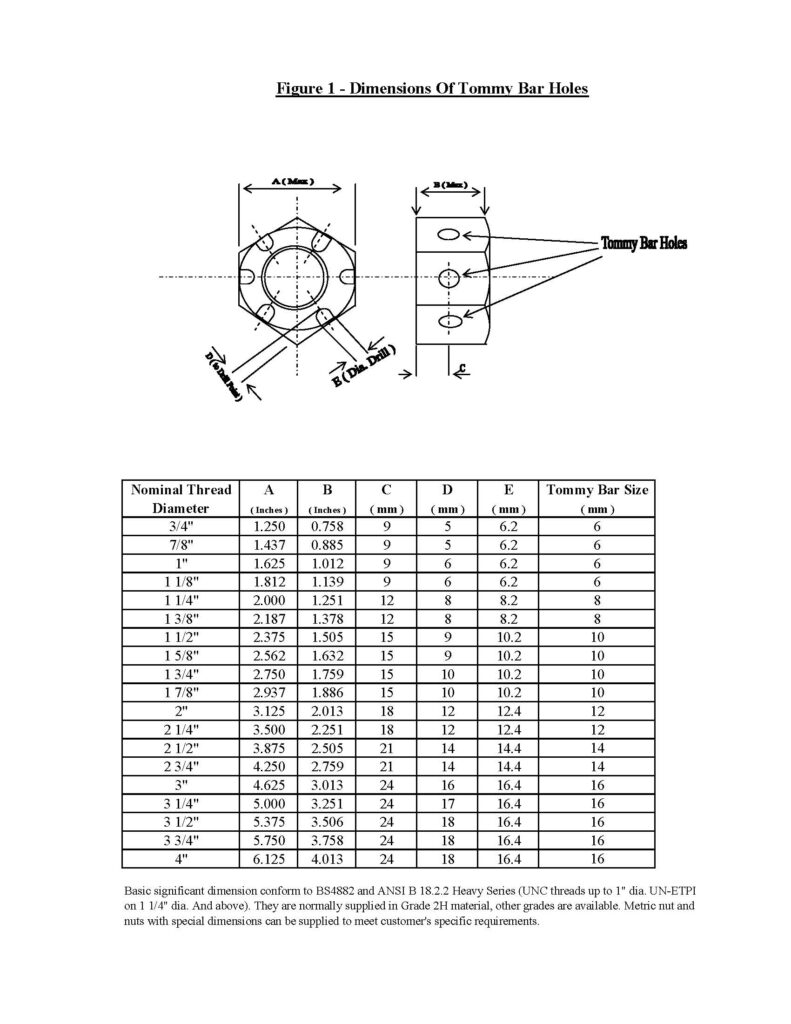

- Hole Configuration:

- Number and placement of tommy bar holes are standardized or customizable.

- Coatings and Finishes:

- PTFE, Fluorocarbon.Xylan 1070,Xylan 1424,xylan 1425 Coated

Tommy-bar-holes-dimensions

Tommy bar hole nuts, also known as drilled hole nuts, are specialized fasteners that include holes on their perimeter for inserting a tommy bar or rod to allow for manual tightening or loosening. These nuts are commonly used in applications where wrenches cannot be used or where the nut needs to be frequently adjusted.