China Manufacturer of EN 1514-2 Spiral Wound Gasket

What is Spiral Wound Gasket ?

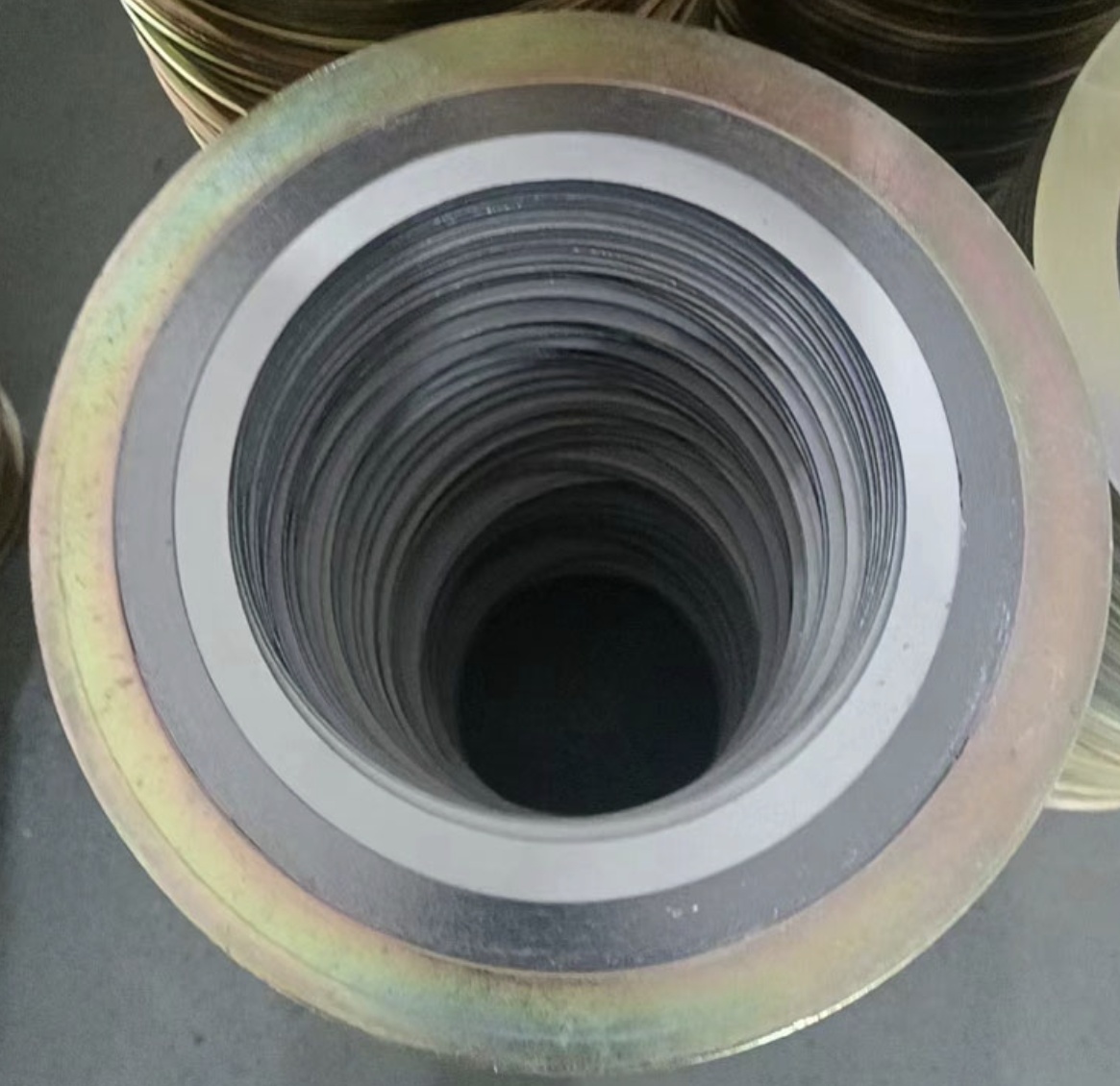

SWG, The spiral wound gasket is semi-metallic, comprising of a spirally wound v-shaped stainless steel strip and a non-metallic filler material, such as graphite or PTFE. Also on the gasket, is a solid outer ring used for centering and controlling compression.

According to the need of the mating flange, the gasket is provided with an outer ring, an inner ring or both outer and inner rings. The outer ring serves as a compression stop, anti-blowout device, which properly centers the gasket on the flange. The inner ring acts as a compression stop and is used to fill the annular space between the flange bores and the gasket inside diameter to minimize trubulence of process fluids and erosion of flanges faces. The spiral wound outer or inner rings are used primarily as reinforcement and are chosen instead of a solid metal ring, because of lower costs or because of limited space when the use of a solid metal ring would be prohibited due to the difficulty in fabrication or usage.

Spiral Wound Gasket Types

The standard spiral wound gasket can be categorized in four styles: reinforce (Style R), inner ring with reinforce (Style RIR), centering gasket (Style CG), centering gasket with inner ring (Style CGI)

1)Style R

Style R is the basic type of spiral wound gasket. Style R’s inner diameter and outer diameter has a few laps metal strips that do not fill the fillers. They maintain the compression and sealing. The Style R spiral wound gasket is normally used for tongue and groove, male and female type joint of flanges.

2)Style RIR

The inner ring is between the bore diameter and the inner diameter of the gasket. It is designed to prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion at flange faces. It’s used for male and female flanges.

3)Style CG

The centering ring accurately make the spiral ring on flange face. It provides an extra radial strength to protect the spiral ring. Style CG gaskets are suitable for flat face flange and raised face flange.

4)Style CGI

The style CGI spiral wound gasket is combined the advantages of centering ring and inner ring. Suitable for high temperature and high pressure. It can be used for above Class 900, corrosive medium or other harsh working conditions.

Spiral wound gaskets also have some other special types gasket, like style HE, style 625 and etc. It can be used in special application.

EN 1514-2

Dimension of EN 1514-2 Spiral Wound Gasket

to be used with Flanges acc. to DIN EN 1092-1

| DN | ID (d1) | ID (d2) | OD (d3) | |

| PN 10-320 |

PN 10-320 |

PN 10-40 |

PN 64-320 |

|

| 10 | 18 | 24 | 36 | 36 |

| 15 | 22 | 28 | 40 | 40 |

| 20 | 27 | 33 | 47 | 47 |

| 25 | 34 | 40 | 54 | 54 |

| 32 | 43 | 49 | 6 | 6 |

| 40 | 48 | 54 | 70 | 70 |

| 50 | 57 | 66 | 84 | 84 |

| 65 | 73 | 82 | 102 | 104 |

| 80 | 86 | 95 | 115 | 119 |

| 100 | 108 | 120 | 140 | 144 |

| 125 | 134 | 146 | 168 | 172 |

| 150 | 162 | 174 | 196 | 200 |

| 175 | 183 | 19 | 221 | 227 |

| 200 | 213 | 225 | 251 | 257 |

| 250 | 267 | 279 | 307 | 31 |

| 300 | 318 | 330 | 358 | 366 |

| 350 | 363 | 37 | 40 | 413 |

| 400 | 414 | 426 | 458 | 466 |

| 450 | 460 | 478 | 526 | 551 |

| 500 | 518 | 530 | 566 | 574 |

| 600 | 618 | 630 | 666 | 674 |

| 700 | 718 | 730 | 770 | 778 |

| 800 | 818 | 830 | 874 | 882 |

| 900 | 910 | 930 | 974 | 982 |

| 1000 | 1010 | 1030 | 1078 | 1086 |

| 1200 | 1210 | 1230 | 1280 | 1290 |

| 1400 | 1420 | 1450 | 1510 | |

| 1600 | 1630 | 1660 | 1720 | |

| 1800 | 1830 | 1860 | 1920 | |

| 2000 | 2020 | 2050 | 2120 | |

| 2200 | 2230 | 2260 | 2330 | |

| 2400 | 2430 | 2480 | 2530 | |

| 2600 | 2630 | 2660 | 2730 | |

| 2800 | 2830 | 2860 | 2930 | |

| 3000 | 3030 | 3060 | 3130 | |

EN 1514-2 Spiral Wound Gasket Materials

The material construction of a spiral wound gasket is based upon the required operating conditions, typically temperature, pressure and substance. For example, a typical standard spiral wound gasket could be made up of a 316 Stainless Steel inner ring and winding with a graphite filler, and a carbon steel outer ring.

To allow for various chemical compatibilities and pressure/temperature requirements, a selection of filler materials are available, including graphite, PTFE, Non-asbestos and Mica.

Filler Materials

| Filler Materials | Temperature Range | Max PSI/BAR | PN Range | Colour Coding |

| Graphite | min -200 max 550 °C | 250 bar | 10- 320 | Grey Stripe |

| PTFE | min – 200 max 250 °C | 100 bar | 10- 320 | White Stripe |

| Nonas | min – 100 max 250 °C | 100 bar | 10-320 | Pink Stripe |

| Mica | min -200 max 1000 °C | 100 bar | 10-320 | Light Green Stripe |

Spiral Winding Materials

| Winding Materials | Temperature Range | Max PSI/BAR | PN Range | Colour Coding |

| 304 Stainless Steel | min-250 max 550 °C | 650°C | 10-320 | Yellow |

| 316L Stainless Steel | min – 100 max 550 °C | 800°C | 10-320 | Green |

| 347 Stainless Steel | min -250 max 550 °C | 870°C | 10-320 | N/A |

| 321 Stainless Steel | min-250 max 550 °C | 870°C | 10-320 | N/A |

| Monel 400 | min -125 max 600 °C | 800°C | 10-320 | Orange |

| Nickel 200 | min – 250 max 600 °C | 600°C | 10-320 | Red |

| Titanium | min – 250 max 350 °C | 450°C | 10-320 | Purple |

| Hastelloy B-2 | min – 200 max 450 °C | 500°C | 10-320 | Brown |

| Hastelloy C-276 | min -200 max 450 °C | 450°C | 10-320 | Beige |

| Inconel 600 | min – 100 max 950 °C | 1000°C | 10-320 | Gold |

| Incoloy 825 | min -100 max 450 °C | 450°C | 10-320 | Gold |

Applications of EN 1514-2 Gasket

- Oil & Gas Industry: Pipelines, valves, and equipment flanges.

- Petrochemical Plants: Sealing in high-temperature reactors.

- Power Generation: Steam turbines and heat exchangers.

- Chemical Industry: Sealing chemical transport systems.

EN 1514-2 Spiral Wound Gasket Order specification.

Spiral Wound Gasket CGI Style to suit DIN Flanges PN16 Materials: SS304+Graphite, Inner Ring: SS304; Outer Ring: Carbon Steel

Spiral Wound Gasket CGI Style for EN 1092-1 Flanges PN16 Materials: SS316 filler Graphite, Inner Ring: SS316; Outer Ring: Carbon Steel

Spiral Wound Gaskets are widely used sealing components designed for high-pressure and high-temperature applications. These gaskets comply with EN 1514-2, which specifies dimensions and tolerances for gaskets intended for use with flanges complying with EN 1092-1 (steel flanges).