Zinc Nickel + PTFE Xylan 1070 Coated Stud bolts A194 B7

China manufacturer and exporter of Zinc Nickel + PTFE Xylan 1070 Coated Stud bolts A194 B7

Stud bolts with a Zinc-Nickel + PTFE (Xylan) coating combine the properties of a corrosion-resistant alloy base layer (Zinc-Nickel) with a durable, low-friction polymer topcoat (PTFE). This dual-coating system is ideal for applications in harsh environments, such as offshore platforms, refineries, and chemical plants.

- Zinc-Nickel Coating or Zinc-Nickel Plating

- Provides excellent corrosion resistance, especially against salt spray and acidic environments.

- Contains approximately 12–18% nickel, which enhances durability and adhesion.

- Acts as a sacrificial layer to protect the base metal from corrosion.

- PTFE (Xylan) Topcoat:

- A fluoropolymer-based coating that reduces friction, improving the ease of installation and preventing galling or thread seizing.

- Adds chemical resistance and extends the life of the bolt under extreme conditions.

- Available in various colors for identification and aesthetic purposes.

- Xylan 1070 coating:Xylan 1070 Coating is a high-performance PTFE (Polytetrafluoroethylene) coating that is primarily used for its exceptional low-friction properties, chemical resistance, and corrosion protection. It is often applied to fasteners, such as stud bolts, to enhance their performance in demanding industrial environments

- Xylan 1070 can withstand temperatures ranging from -195°C to 260°C (-319°F to 500°F), which makes it effective in both cryogenic and high-temperature applications.

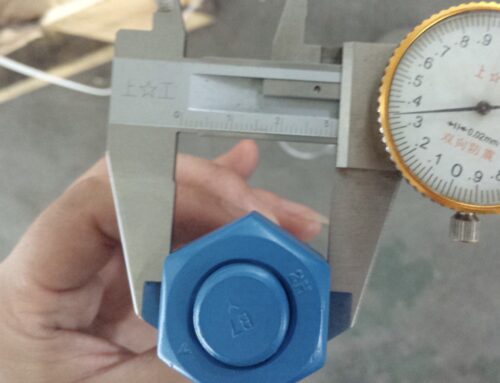

- Xylan 1070 blue color is the most popular color in PTFE coating on the stud bolts and nuts

Zinc Nickel + Xylan 1070 COATED Stud BOLT Common Applications

- Offshore Oil & Gas Platforms: Resistance to seawater and harsh marine conditions.

- Chemical Processing Plants: Protection against acidic and caustic environments.

- Power Plants: Suitable for high-temperature bolting applications.

- Automotive and Aerospace Industries: Lightweight corrosion-resistant solutions for critical fasteners.

Zinc Nickel + PTFE COATED Stud BOLT Testing and Performance

- Salt Spray Resistance: Zinc-Nickel + PTFE coatings typically withstand up to 1,000–2,000 hours of salt spray testing (ASTM B117).

- Adhesion: The PTFE layer adheres strongly to the Zinc-Nickel base, preventing peeling or flaking.

- Abrasion Resistance: PTFE coatings add a protective layer against mechanical wear.

Stud bolts which could be applied on Zinc Nickel + PTFE Xylan 1070 COATING

Alloy Steel Stud bolt

- Grades: ASTM A193 B7, B7M

- Applications: High-temperature and high-pressure environments, such as refineries and chemical plants.

- Advantages: High strength and moderate corrosion resistance

Low-Temperature Carbon Steel Stud bolt

- Grades: ASTM A320 L7, L7M

- Applications: Cryogenic and low-temperature environments, such as LNG plants.

- Advantages: High toughness at low temperatures.

ASME B1.1 – Unified Inch Screw Threads (UN and UNR Thread Form)

- Application: Defines thread forms and tolerances for fasteners, including stud bolts.

- Details on Stud Bolts:

- Specifies thread classes such as 2A/2B and 3A/3B for stud bolts, which impact fit and load-bearing capacity.

ASME B18.31.2

Continuos and double-end studs, inch series. Suppliers of ASME B18.31.2. Go to the complete list.

ASME B18.31.2 is part of the ASME B18 series and covers the dimensions and specifications for shoulder bolts and similar fasteners. This standard outlines the exact requirements for various shoulder bolts

Zinc Nickel + PTFE Xylan 1070 Coated Stud bolts A194 B7 order spec

Product Name: Zinc Nickel + PTFE Xylan 1070 COATED Stud bolt and Nuts

Standard: ASME B18.31.2

Material for Stud Bolt: Alloy Steel ASTM A193 Grade B7

Material for Nut: ASTM A194 Grade 2H

Parts: with Two Heavy Hex Nuts

Surface Treatment: Zinc Nickel Plating + Xylan 1070 Blue coating