In this article, we will learn about the stud bolt and its materials selection,size etc.

What is the stud bolt?

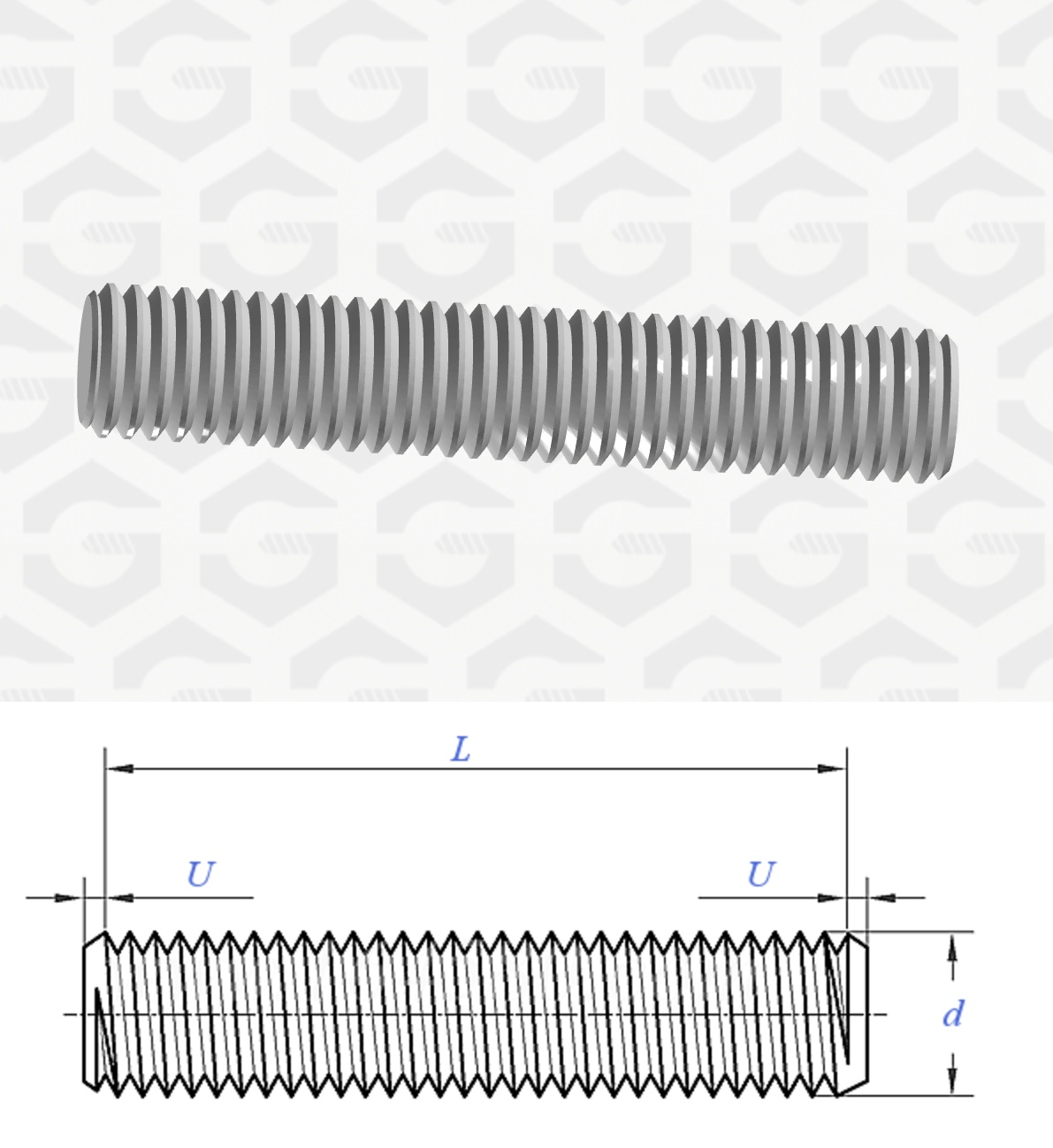

A stud bolt is a type of fastener commonly used in industrial and construction applications. It consists of a threaded rod with threads on both ends

An full set of stud bolt connections is usually consisited with 2 Hex nuts and the stud. Sometimes, washers and additional nuts may be used. In high-pressure piping and pipeline flange connections, stud bolts are widely used.

Stud bolt Type

1. Full-Thread Stud Bolts or Continuous Thread Studs

A full-thread stud bolt is a type of fastener where the entire length of the rod is threaded. It does not have a head and is designed to be used with nuts on both ends. This type of stud bolt is highly versatile and widely used in Pipe Flanges connections

2. Tap-End Stud Bolts

Have threads on both ends, but one end has a shorter thread length compared to the other.

3. Double-End Stud Bolts

A double-end stud bolt is a type of fastener with threads of equal or specified lengths on both ends, separated by an unthreaded shank in the middle. Unlike full-threaded bolts, the central shank provides a smooth, non-threaded surface, which can help reduce stress concentration and simplify alignment.

4. Reduced Shank Stud Bolts

A reduced shank stud bolt is a type of fastener that features a central shank (unthreaded portion) with a smaller diameter than the threaded ends.

5. Collar Stud Bolt

A collar stud bolt is a specialized fastener that features a flange-like collar in the middle of the shaft, with threaded ends on both sides. The collar acts as a spacer, stopper, or alignment aid, providing precise positioning and additional functionality compared to standard stud bolts

Stud Bolt Threads Types

Types of Threads in Stud Bolts

Stud bolts can have various thread types, depending on the application, industry standards, and mechanical requirements.

UN and Metric thread are the most common thread type for stud bolts

1. Unified National Thread (UN/UNR)

- Description: A standardized thread system used in the United States, featuring a 60° thread angle.

- types

- UNC (Coarse Thread): Widely spaced threads for quick assembly and better resistance to stripping in softer materials.

- UNF (Fine Thread): Closely spaced threads for better strength and precision.

2. Metric Thread

- Standardized thread system used globally, defined by ISO standards. Threads are specified by their pitch (distance between threads in millimeters).

- Types

- Coarse Thread (M): The default thread for general applications.

- Fine Thread (MF): Used when higher strength or precision is required.

Stud Bolt Standards

Stud bolts are extensively used in industrial and construction applications, particularly in piping, pressure vessels, and structural assemblies.

1. Dimensional Standards

These standards specify the dimensions of stud bolts, including length, thread size, and pitch.

- ASME B16.5 & ASME B16.47: stud bolt dimensions for flanges, covering sizes, materials, and thread engagement for different flange ratings.

- ASME B18.2.1: Specifies dimensions for standard bolts, including stud bolts, with hex and square bolts.

- ISO 898-1: For metric stud bolts, defines mechanical properties, grades, and testing requirements.

- DIN Standards (DIN975 DIN 976): Cover the general properties and dimensions of threaded rods and stud bolts.

2. Thread Standards

Threads on stud bolts follow specific guidelines to ensure compatibility.

- ANSI/ASME B1.1: For Unified Thread Standard (UNC, UNF), commonly used in North America.

- ISO 68-1 / ISO 261 / ISO 262: Define metric thread standards.

Materials for Stud bolt

Materials used for stud bolts must comply with these standards to ensure mechanical strength and corrosion resistance.

Grade B7 and B7M are the most frequently used A193 material grades. For low-temperature services, ASTM A320 Gr L7, L7A, and L7B are used. Other stud bolt materials include the following:

1. Carbon Steel

- Applications: General-purpose applications in low-pressure and low-temperature environments.

- Common Grades:

- ASTM A307 Grade A/B: Low-strength carbon steel for non-critical applications.

- ASTM A36: Standard carbon steel with good weldability and strength.

2. Alloy Steel

- Applications: High-pressure and high-temperature applications such as power plants, refineries, and petrochemical plants.

- Common Grades:

- ASTM A193 Grade B7: Chromium-molybdenum steel; widely used in high-temperature environments.

- ASTM A193 Grade B16: Vanadium-enhanced alloy steel for high-pressure, high-temperature applications.

- Properties: Higher strength, resistance to thermal expansion, and better wear resistance than carbon steel.

3. Stainless Steel

- Applications: Corrosive environments, including marine, chemical, and food processing industries.

- Common Grades:

- ASTM A193 Grade B8: Austenitic stainless steel (equivalent to SS 304).

- ASTM A193 Grade B8M: Austenitic stainless steel with molybdenum (equivalent to SS 316), offering improved corrosion resistance.

- ASTM A320 Grade L7: For low-temperature applications.

- Properties: Excellent corrosion resistance, durability, and aesthetic appeal.

4. Nickel Alloys

- Applications: Extreme environments with high corrosion or temperatures, such as offshore platforms, chemical plants, and aerospace.

- Common Grades:

- Inconel 718: Excellent resistance to high temperatures and corrosion.

- Monel 400: Superior resistance to saltwater and acidic environments.

- Hastelloy C276: Exceptional resistance to chemical attack in harsh conditions.

- Properties: High strength, excellent corrosion resistance, and thermal stability.

5. Duplex and Super Duplex Stainless Steels

- Applications: Aggressive environments like seawater, sour gas, and chemical processing plants.

- Common Grades:

- ASTM A182 Grade F51 (Duplex 2205): Balanced strength and corrosion resistance.

- ASTM A182 Grade F55 (Super Duplex 2507): Higher corrosion resistance and strength.

- Properties: Combination of austenitic and ferritic structures, offering high strength and resistance to stress corrosion cracking.

6. Low-Temperature Steels

- Applications: Cryogenic and sub-zero environments, such as LNG plants.

- Common Grades:

- ASTM A320 Grade L7: Alloy steel for low-temperature service.

- ASTM A320 Grade L43: Higher strength alloy steel for low-temperature conditions.

7. Exotic Materials

- Applications: Specialized industries like nuclear, aerospace, or advanced chemical processing.

- Common Materials:

- Titanium Alloys: Lightweight, strong, and highly corrosion-resistant.

- Zirconium: Excellent resistance to acidic environments.

- Tantalum: Exceptional resistance to chemical attack.

Coatings and Surface Treatments for Stud bolt

To enhance corrosion resistance and durability, stud bolts can also be coated or treated. Common options include:

- Hot-Dip Galvanizing: For general corrosion resistance.

- Zinc Plating: Economical for mild corrosion protection.

- PTFE Coating (Teflon): For extreme chemical resistance.

- Black Oxide: For mild corrosion protection with a matte finish.

Selection of Stud Bolt Materials

The material of the stud bolt mainly depends on the process design temperature and flange materials. however, there are many other parameters that must be considered. The following image from blog.projectmaterials.com provides rough guidance on the stud bolt material selection based on design temperature and flange material: