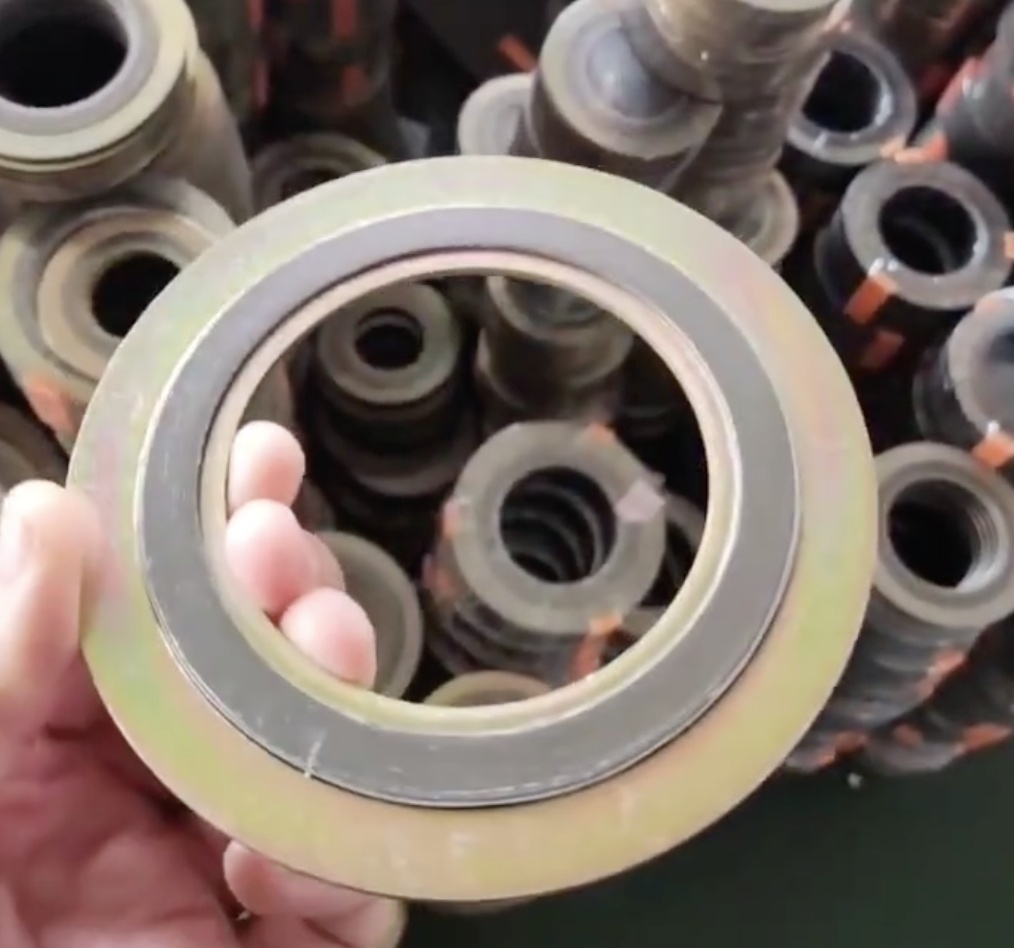

China manufacturer of SWG 316L/FG SS 316L with Graphite Filler Spiral Wound Gasket

Spiral Wound Gaskets are high-performance sealing components widely used in critical applications such as pipelines, flanges, and heat exchangers

Spiral Wound Gaskets Structure

A spiral wound gasket typically consists of the following components:

- Metal Windings:

- Material: Typically stainless steel (e.g., SS304, SS316, SS321,Duplex S31803,S32750 ) or other alloys (e.g., Inconel, Monel).

- Function: Provides strength, resilience, and the ability to handle high pressure and temperature fluctuations.

- Filler Material:

- Material: Non-metallic fillers such as graphite, PTFE, or mica.

- Function: Ensures a tight seal by filling the imperfections on the flange surface.

- Graphite: Excellent for high-temperature and high-pressure applications.

- PTFE: Best for chemical resistance in corrosive environments.

- Mica: Suitable for extreme high-temperature environments (e.g., thermal power plants).

- Inner Ring and Outer Rings:

- Inner Ring: Prevents gasket blowout and protects the windings from erosion.

- Outer Ring: Provides a centering guide during installation and prevents over-compression.

- Material: Typically stainless steel or Galvanized CS (carbon steel ) with optional coatings.

Types of Spiral Wound Gaskets

suitable for high pressure and temperature applications for TG/male/ female flange .

For example: SS304/FG.

SWG with inner and outer ring, for raised & flat face flange.

For example: SS304/SS304+FG/CS

CG Type Spiral Wound Gasket:

SWG with only outer ring, for raised / flat face flange.

For example: SS304/FG CS

RIR Type Spiral Wound Gasket:

SWG with only inner ring, for male / female flange.

- Basic Type or R Type Spiral Wound Gasket :

- Consists only of windings and filler material.SWG with only filler and winding,

- Suitable for tongue-and-groove or male-female flange faces.

- With Inner Ring or RIR Type Spiral Wound Gasket:

- Spiral Wound Gasket Style RIR is a sealing element and inner metal ring, with Flexible Graphite filler material.

- Used in high-pressure and high-temperature applications.

- With Outer Ring (Centering Ring): CG Type Spiral Wound Gasket:

SWG with only outer ring, for raised / flat face flange. Common in raised-face flanges. - With Inner and Outer Rings: CGI Type Spiral Wound Gasket:

- Combines the features of both inner and outer rings, providing the highest level of reliability.

- Suitable for critical applications such as high-pressure steam or hydrocarbons.

Spiral wound gaskets Material slection

Spiral wound gaskets are designed for ASME B16.20 and ANSI B16.5/B16.47 flanges. Spiral wound gaskets are available for classes 150 to 2500. Custom filler, winding strip, guide ring and inner ring materials are available upon request.

| Winding Materials: | Max. Temp. Range |

| Stainless Steel 304 | 760°C |

| Stainless Steel 316L | 760°C |

| Filler Materials: | |

| Graphite | 523°C |

| PTFE | 260°C |

| Guide Ring Materials: | |

| Carbon Steel | 538°C |

| Inner Ring Materials: | |

| Stainless Steel 304 | 760°C |

| Stainless Steel 316 | 760°C |

Standards for Spiral Wound Gaskets

- ASME B16.20: Specifications for metal gaskets for pipe flanges.

- EN 1514-2: European standard for spiral wound gaskets.

- API 601: Standards for gaskets in refinery applications.

Spiral Wound gasket order specification

- GSKT SPW 316L CL150, 10in

- Design spec ASME B16.20

- Design spec, flange(s) ASME B16.5

- Service SOUR

- Pressure designation CL 150

- Mat, windings STAINLESS STEEL 316L

- Mat, filler GRAPHITE

- Mat, inner ring STAINLESS STEEL 316L

- Mat, centering ring STAINLESS STEEL 316L

- Mat spec, windings GRADE TP316L

- Mat spec, inner ring GRADE TP316L

- Mat spec, centering ring GRADE TP316L

- Mandatory add reqrmts NACE MR0175