Cylinder Restraint Kit also called Cylinder Seismic Restraint Kit.

A Cylinder Seismic Restraint Kit is a specialized safety system designed to secure gas cylinders against the forces generated during an earthquake or other seismic activities. These kits are essential in seismically active regions, such as New Zealand ,Austrilia or areas along the Pacific Ring of Fire, where earthquakes are frequent. By stabilizing gas cylinders, these kits minimize the risk of accidents, such as tipping, rupturing, or gas leaks, during seismic events.

Cylinder Seismic Restraint Kit is designed to secure gas cylinders, tanks, or other critical equipment against tipping, sliding, or falling.Often used in seismic zones to comply with safety regulations.Suitable for outdoor or corrosive environments due to the stainless steel’s durability.

We can produce high quality Stainless steel Cylinder Restraint Kit.

Stainless steel 3 Strap Cylinder Restraint Kit normally is recommended used in outdoor serivce,as stainless steel has good corrosion resistance ductility, and high strength.

Stainless steel cylinder restraint Kit is made of SS304 Stainless steel, with SS304 Perforated Steel Strap,SS304 Mounting Brackets,and SS 304 Screws

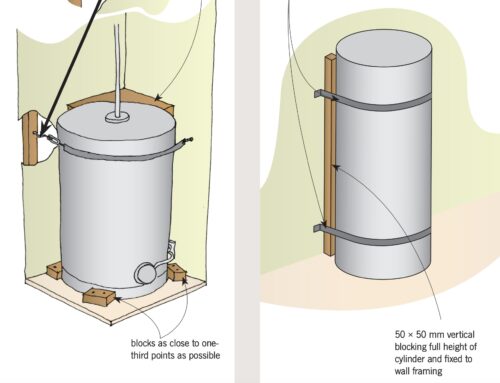

The Stainless 3 Strap Seismic Cylinder Restraint Kit consists of 6 meters of perforated Stainless Steel strap and all brackets, bolts, screws & tensioning devices required to make a 3 strap installation of this kit.

These are used for Seismic Earthquake Protection and security for hot water cylinders and storage vessels, as well as meeting requirements for the restraint of new installation

All cylinders must be protected from being knocked over, falling and/or impact damage to comply with AS4332-2004, section 5.2(g). This is regardless of whether full or empty or in or out of operation.

All cylinders, as per G12, must be suitably restrained against seismic activity.

While our Cylinder Restraint Kits offer a safe and convenient load restraining in a variety of industrial applications.

NZS 4219:2009 is the New Zealand standard that provides guidelines for the seismic performance of engineering systems in buildings, including the restraint of non-structural elements like gas cylinders. This standard is particularly relevant for designing and installing Cylinder Seismic Restraint Kits to ensure safety and compliance in seismic events.

NZS 4219:2009

Seismic performance of engineering systems in buildings

Sets out the criteria for the seismic performance of engineering systems related to a building’s function. This standard will be particularly useful for sub-trade work in multi-storey apartment and commercial buildings. It covers the design, construction and installation of seismic restraints for engineering systems such as air-handling units, tanks, cabinets, pipework and ductwork. To demonstrate compliance with the New Zealand Building Code’s earthquake resistance requirements, it must be read along with Verification Method B1/VM1. Buildings with importance level 5, large mass items, structures external to the building, lifts, building contents, and fire sprinkler systems are excluded from this Standard.

How Cylinder Seismic Restraint Kit Works

- Securing Cylinders: The kit holds the cylinder tightly in an upright position, preventing tipping.

- Absorbing Shocks: The system helps distribute and absorb the seismic forces to reduce cylinder movement.

- Reducing Risks: Prevents the cylinder from falling or breaking its valve, which could lead to gas leaks, fires, or explosions.

Benefits of Using a Cylinder Seismic Restraint Kit

- Prevents Accidents: Secures cylinders during earthquakes to avoid tipping or rupturing.

- Protects Lives and Property: Reduces hazards posed by flying cylinders or gas leaks.

- Regulatory Compliance: Meets seismic safety standards and workplace safety regulations.

- Versatile Applications: Suitable for industrial, healthcare, and laboratory environments.

Why select Stainless STEEL SS304 Cylinder Restraint Kit?

304 Stainless Steel:

Resistant to rust and corrosion, making it ideal for harsh or corrosive environments (e.g., marine, chemical, or industrial settings).

Provides high tensile strength and durability.