China Manufacturer of SS304 Spiral Wound Gasket with Inner & Outer Rings SS304 Graphite CGI ASME B16.20

What is Spiral Wound Gasket?

Spiral Wound Gasket shorten as SWG,which is a sealing material for Pipe flanges.

A Spiral Wound Gasket (SWG) is a type of industrial gasket that is widely used in high-temperature, high-pressure, and corrosive environments. It consists of a V-shaped metal strip and a softer filler material that is wound in a spiral fashion to create a resilient sealing surface

The spiral wound gasket is semi-metallic, comprising of a spirally wound v-shaped stainless steel strip and a non-metallic filler material, such as graphite or PTFE. Also on the gasket, is a solid outer ring used for centering and controlling compression. This minimizes the risk of material creep through over-tightening.

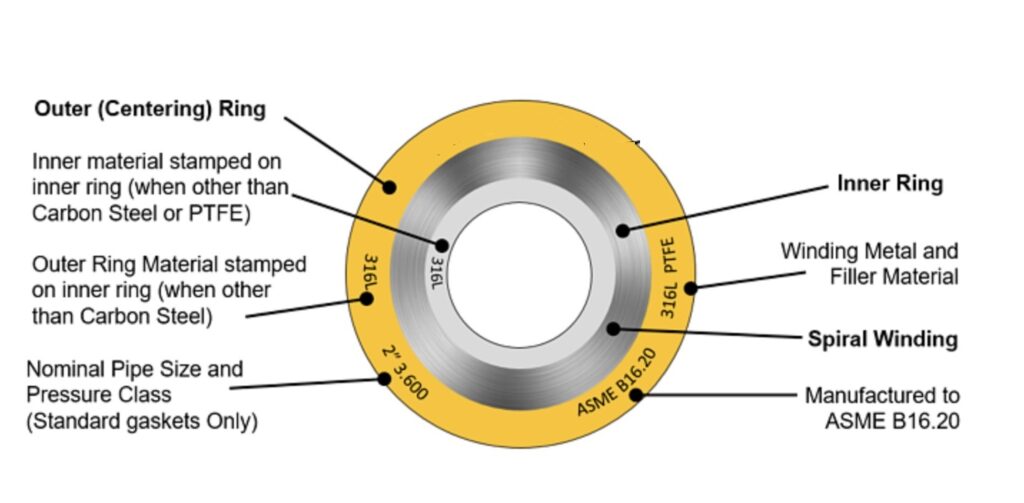

How to identify metal and filler materials . The image below shows the marking and structure of the spiral wound gasket

What is SS304 FG in gasket?

FG is shorten by Flexible graphite

Chemical Composition (ASTM A240)

| SX | oC | Mn | P | S | Si | Cr | Ni |

| 304 304L |

0.08 max 0.03 max |

2.0 max |

0.045 max |

0.030 max |

1.0 max |

18.0 to 20.0 |

8.0 to 10.50 8.0 – 12.0 |

Mechanical Properties at Room Temperature

| 304 | 304L | |||

| Typical | Minimum | Typical | Minimum | |

| Tensile Strength, MPa | 600 | 515 | 590 | 485 |

| Proof Strength, (Offset 0.2 %), MPa | 310 | 205 | 310 | 170 |

| Elongation (Percent in 50mm) | 60 | 40 | 60 | 40 |

| Hardness (Brinell) | 170 | – | 170 | – |

| Endurance (fatigue) limit, MPa | 240 | – | 240 | – |

R Type Spiral Wound Gasket

Basic Type

* Basic construction type, inner and outer diameters are reinforced with several piles of metal without filler to give greater stability and better compression characteristics.

* Recommended flange tongue and groove, male to female and flat face to recess.

* General and critical duties.

IR Type Spiral Wound Gasket

Inner Ring Type

* Solid inner metal ring acts as a compression stopper. To prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion, damages of gasket between flange bore and the inside diameter, the annular space is filled up by solid inner metal ring.

* Suitable for male and female pipe flanges.

* General duties.

CG Type Spiral Wound Gasket

Outer Ring Type

* Solid outer ring accurately locates the gasket on the flange face to give the additional radial strength to prevent the gasket blowout and acts as a compression limiter. In case of installing the outer ring, it is very easy to install the gasket to flange face because the end of outer ring will touch at bolts.

* Suitable for use with flat face and raised face flanges. For class 900 and above an internal ring is recommended.

* General and critical duties.

CGI Type Spiral Wound Gasket

Inner & Outer Rings Type

* A inner ring and outer ring type gasket will give an additional compression limiting stopper for gasket inner and outer side. It will prevent the corrosions on flange face at annular space.

* Suitable for use with flat face and raised face flanges and specified for high pressure / temperature service – Class 900 and above or where corrosive or toxic media are present.

* General and critical duties.

SS304 Spiral Wound Gasket order specification

Type: CGI

Size : 8 Inch

Design Pressure : 900LB

Material of Ring: SS304 Inner Ring and Carbon Steel Outer Ring

Material of Base Ring: SS304 Hoop Filled with Flexible Graphite

Manufacture Standard: ASME B16.20