China Manufacturer of Spiral Wound Gasket 316L/FG basic type SWG R

Spiral Wound Gaskets (SWG) are widely used as high integrity and sustainable gaskets. We offer a complete range of spiral wound gaskets, Standard and non-standard spiral wound gasket and spiral wound gasket material . SWG can be made from a large selection of alloys and filler materials in a variety of shapes and sizes.

Spiral wound gasket comprise a mix of metallic and filler material. Generally, the gasket has a metal (normally stainless steel) wound outwards in a circular spiral (other shapes are possible) with the filler material (generally a flexible graphite) wound in the same manner but starting from the opposing side. This results in alternating layers of filler and metal. The filler material in these gaskets acts as the sealing element, with the metal providing structural support.Spiral wound gaskets are designed for ASME ,DIN,JIS flanges.There are usually 4 types of spiral wound gasket ,R/IR/CG/CGI.

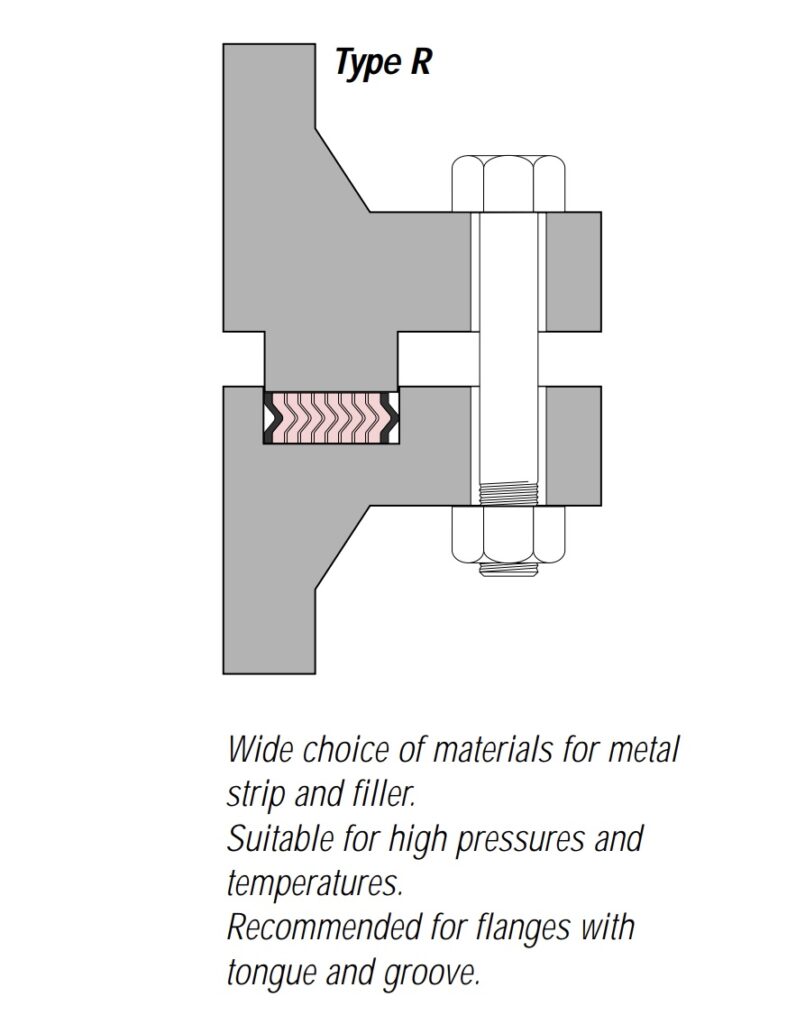

Basic type Spiral Wound Gasket is also called R type Spiral Wound Gasket,SWG with only filler and winding, suitable for high pressure and temperature applications for TG/male/ female flange . Most popular SWG material is 316/FG,316L/FG,which means, Filler: graphite,Wound material:316/316L

Style R – Is comprised of a sealing element, additional plies of metal are used at the start and termination of the winding process improving stability and sealing performance. Unlike other styles of spiral wound gasket compression of the sealing element is controlled by the use of the correct flange face configuration, style R gaskets are suitable for use on tongue and groove, male and female and flat to groove flanged connections.

Spiral Wound Gaskets Materials:

- Gasket Hoop

| Winding Material | Max Temperature | Colour |

| SS304 | 650°C | Yellow |

| SS316L | 800°C | Green |

| SS347 | 870°C | Blue |

| SS321 | 870°C | Turquoise |

| Monel400 | 800°C | Orange |

| Inconel 600 | 1000°C | Gold |

| Inconel 625 | 1000°C | Gold |

| Inconel 800 | 1000°C | White |

| Inconel 825 | 1000°C | White |

| Titanium | 540°C | Purple |

- Gasket Filler

| Filler Material | Max Temperature | Colour |

| Graphite | 550°C | Grey |

| PTFE | 260°C | White |

| Mica | 1000°C | Light Green |

How to choose Filler for Spiral Wound Gaskets

The main sealing part is filler which is made up of SS strip and non- metallic filling tape, the material can be changed according to different chemical compatibility requirements,

Graphite filling strip is supposed to used in high temperature environment,

PTFE filling strip is for acids and other corrosive mediums

Non – asbestos its use increased when the health problems with asbestos became known. Only recommend for low temperature less severe applications due to the rubber content .

Ceramic is in extremely high temperature applications.The filler is not so common as it cannot achieve the same leak tightness as graphite

Common Standards for Spiral Wound Gaskets

- ASME B16.20: Specifications for metal gaskets for pipe flanges.

- EN 1514-2: European standard for spiral wound gaskets.

- API 601: Standards for gaskets in refinery applications.

Sprial Wound Gasket Types

| Types | Style | Flange | Example |

| Basic type SWG | R | Tongue and Groove | SS316L/PTFE 316L/FG |

SWG Inquiry Example for refernece

| Size | Class | Basic Material | Qty |

| 2″ | 150 | 316L/FG | 200 |

| 4″ | 300 | 304/FG | 180 |

| 6″ | 600 | 316L/PTFE | 160 |

| 8″ | 900 | 304/PTFE | 140 |

| 10″ | 1500 | 304/FG/PTFE | 120 |

| 12″ | 2500 | 316L/Mica/PTFE | 100 |