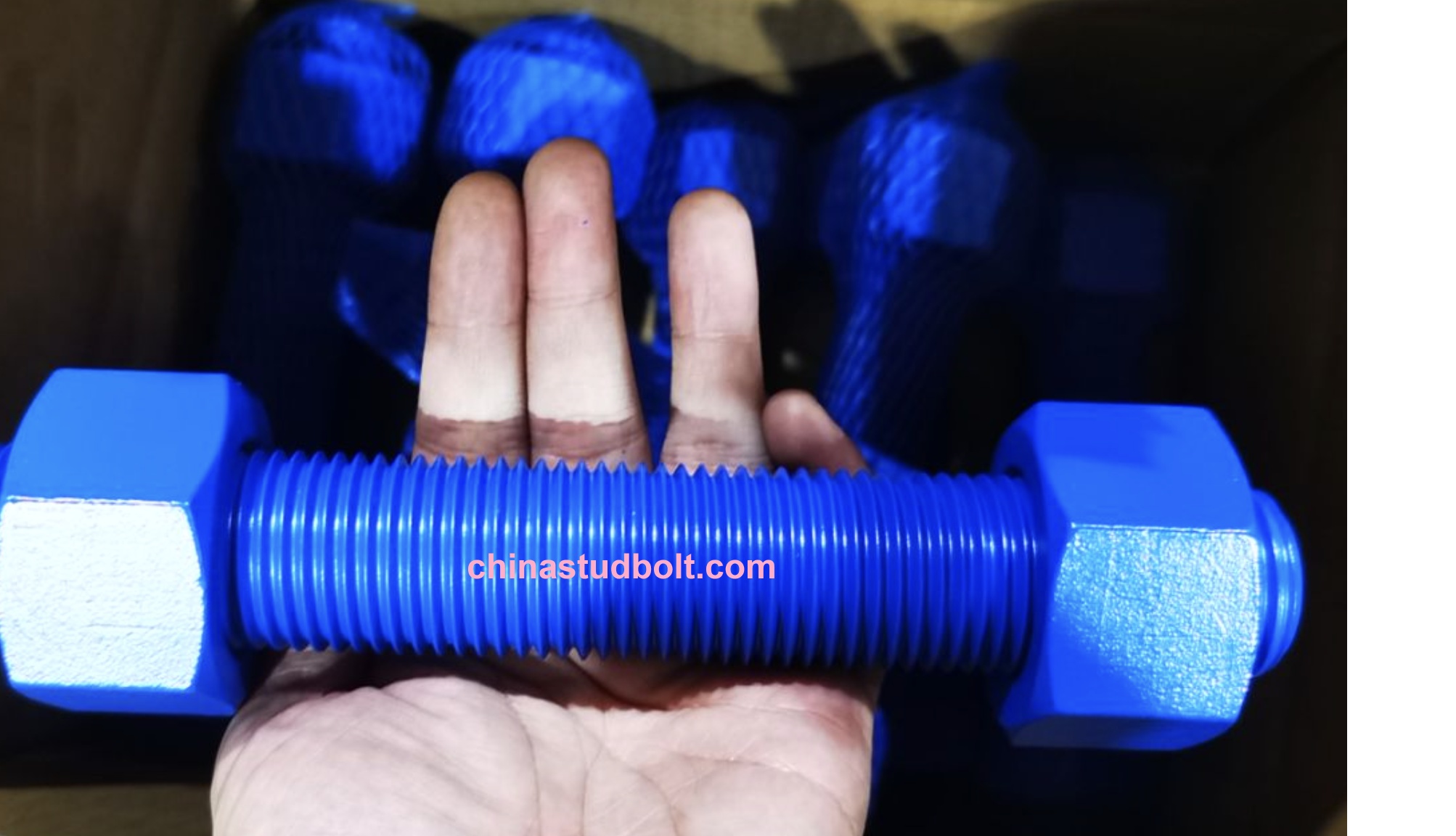

China Professonal manufacturer of PTFE coated ASTM A193 B7 Stud bolt with 2 A194 2H hex nuts

PTFE coated stud bolt is a fastener with a polytetrafluoroethylene (PTFE) coating applied to its surface. This coating enhances the bolts good performance in harsh environments and specific applications.

PTFE coated studs have been used for many years within the bolting industry, especially in any application that requires corrosion resistance or in offshore applications.

ASTM A193 B7 Stud Bolts material is one of the most common grade with PTFE coating for various applications.

PTFE is short for Polytetrafluoroethylene, a synthetic fluoropolymer of tetrafluoroethylene. It is widely known by its brand name Teflon which is a chemical applied to common bolting materials (such as B7 stud bolts) to provide corrosion and chemical resistance.

Normally when we talk about the PTFE coated on the stud bolt and other fasteners,we always refer to Teflon® and Xylan®.

While PTFE coated stud bolts (including Xylan coated studs bolts) have corrosion-resistant properties.

Features of PTFE Coated ASTM A193 B7 Stud Bolts

- Premium Material:

- Stud Bolt: Manufactured from ASTM A193 Grade B7 (Chromium-Molybdenum steel), known for exceptional strength and durability in extreme environments.

- Hex Nuts: Made from ASTM A194 Grade 2H carbon steel, designed to withstand high-pressure applications.

- PTFE Coating Benefits:

- Corrosion Resistance: Protects the bolts and nuts in harsh conditions, including marine, chemical, and industrial settings.

- Low Friction: Facilitates easy installation and removal, reducing wear and tear on components.

- Chemical Resistance: Handles exposure to aggressive chemicals without degrading.

- Applications:

- Ideal for oil & gas, petrochemical, power generation, and marine industries.

- Perfect for pressure vessels, valves, flanges, and other critical equipment.

- Specifications:

- Thread Type: UNC or 8 TPI for larger diameters.

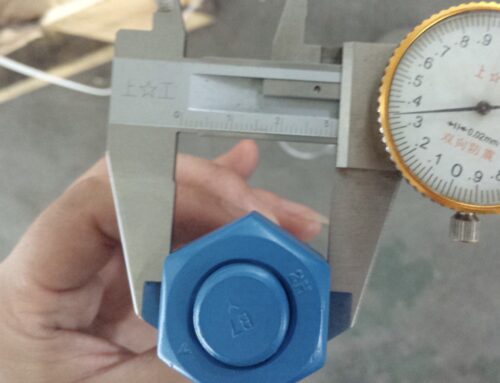

- Coating Thickness: PTFE coating applied to 15-20 microns for optimum performance.

- Available in a variety of sizes, from M12-M100 or 1/2″ to 4″ diameter

- Available in Multiple Colors: Choose from dark blue, green, yellow, or red for easy identification.

Compliance and Certification

- Manufactured to meet ASTM A193 and ASTM A194 standards.

- Material Test Reports (MTRs) and certifications, including chemical composition, mechanical properties, and PTFE coating quality.

Surface:black,galvanized,HDG,blue. FluoroCarbon Coated

Whitford Quality Approved Coater Xylan 1070 Coated Stud Bolt, Xylan Coated Bolts, PTFE Fluorocarbon Coated A193 B7 Stud Bolt &A194 2H NUTS

PTFE Fluorcarbon coating-Surface Coatings XYLAN 1070. XYLAN 1424.

Diameter:1/4″~3 3/4″

Length:20mm~6000mm(usually 12 feet)

Grade :B7

Standard: M6-M100

Material: ASTM A193 B7.

Surface finished: PTFE Xylan Coated.

Standard: ANSI B18.1.1.

Stud bolts, a term used for cut-to-length all thread rod, are used for: bolting together flanges, anchor bolting, as well as general fastening.

What is the PTFE Coating?Is it the same as fluoropolymer?

PTFE is shorten by Polytetrafluoroethylene,which is a synthetic fluoropolymer of tetrafluoroethylene.

This material is quite versatile as it is hydrophobic, resistant to high temperatures, and has a high density. The large application potential and availability makes it a common fluoropolymer for protective coatings.

PTFE is used in industries such as pharmaceuticals, construction, aerospace, and medicine because it is safe in cryogenic temperatures and the insulation it can provide.

Fluoropolymers

This is the base ingredient of many well-known trademarked brands: Teflon™, Xylan™, Fluon™.

Difference Between Fluoropolymers and PTFE

So, what actually is the difference between the two? Is fluoropolymer the same as PTFE?

Basically, yes. They are the same thing.

Xylan is one of the brand names for PTFE and is a trademark brand name.and it is reliable PTFE coating material for stud bolt.

A193 B7 – This is the most common grade for which stud bolts are produced. A193 B7 is a Chrome-moly, Alloy steel that is made to AISI 4140/4142, and it is quenched and tempered.

PTFE coated ASTM A193 B7 Stud bolt with 2 A194 2H hex nuts order specification.

1). STUD BOLT 1-3/4″; 8UN X 300L;

WITH 2 NUTS; BOLT MAT: A193- B7;

NUT MAT.: A194-2H

Surface:PTFE Blue coating

QTY 77 SETS

2).1-1/4″ X 230 MM LONG STUD BOLT + 2NUTS QTY 90 SETS

– STUD A193 B7- NUTS A194 2H Standard:ASME ANSI B18.31.2 / ANSI B18.2.2

THDD L= 230 MM (BLUE) PTFE COATED.