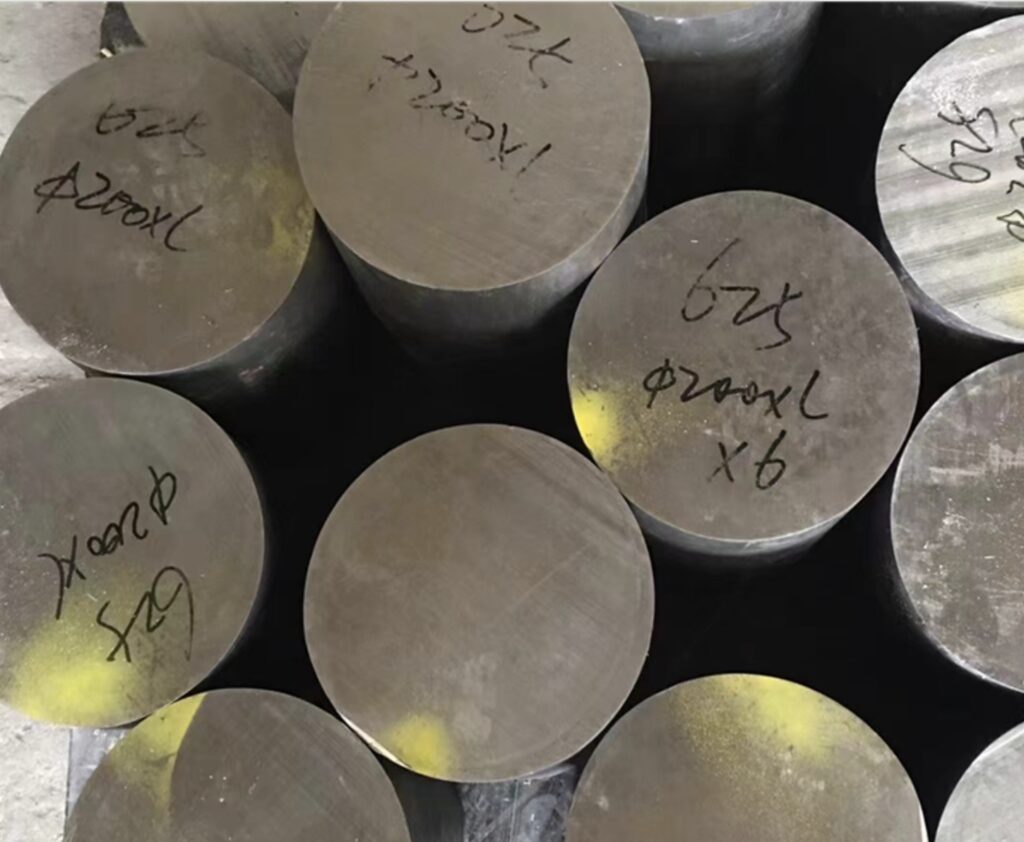

Inconel 625 round bar ASTM B446 UNS N06625 Rod Manufacturer in China

ASTM B446 covers nickel-chromium-molybdenum alloy bars and forgings, specifically for Alloy 625 (UNS N06625), a corrosion-resistant alloy widely used in high-temperature and high-corrosion environments.

Inconel 625 round bar, also known as UNS N06625, is a high-performance alloy primarily composed of 58% nickel and 20% chromium, with additional elements including iron, manganese, silicon, molybdenum, cobalt, aluminum, titanium, niobium, tantalum, phosphorus, and sulfur

Inconel 625 Round Bar Specification

| ASME and ASTM designation | ASTM B446 / ASTM SB446 |

|---|---|

| Dimensions Schedule | ASTM, ASME |

| OD Size Ranges | 5 To 500 mm |

Chemical Composition of UNS N06625

| Element | Composition Range (%) |

|---|---|

| Nickel (Ni) | 58.0 min (remainder) |

| Chromium (Cr) | 20.0–23.0 |

| Molybdenum (Mo) | 8.0–10.0 |

| Iron (Fe) | 5.0 max |

| Columbium (Nb) | 3.15–4.15 |

| Titanium (Ti) | ≤ 0.40 |

| Aluminum (Al) | ≤ 0.40 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

Mechanical Properties of N06625 round bar

| Property | Value |

|---|---|

| Tensile Strength | ≥ 120 ksi (827 MPa) |

| Yield Strength (0.2% offset) | ≥ 60 ksi (414 MPa) |

| Elongation | ≥ 30% |

| Hardness | ≤ 32 HRC (typically softer for machining ease) |

Inconel 625 Round Bar Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

benefit of N06625 round bar

Corrosion Resistance:

- Excellent resistance to oxidation and corrosion, especially in highly acidic and marine environments.

- Resistant to pitting, crevice corrosion, and stress-corrosion cracking.

High-Temperature Strength:

- Maintains strength and oxidation resistance up to 980°C (1800°F).

Mechanical Strength:

- High yield and tensile strength without the need for precipitation hardening or cold working.