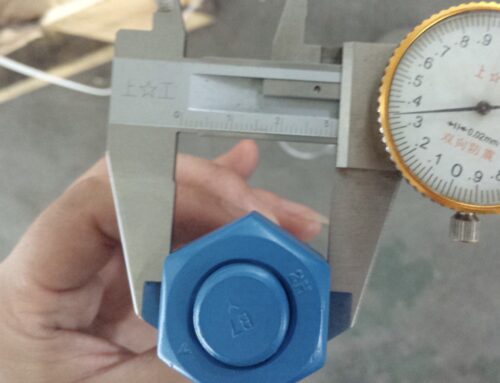

Hot dip galvanized A193 b7 stud bolt

Hot dip galvanized stud bolt is the A193 B7 Stud bolt with Hot Dip Galvanized according to ASTM A153 standard

We are the professional manufacturer of Hot dip galvanized A193 b7 stud bolts in China.

Hot dip galvanized,short for HDG, which is Hot dip galvanizing, according to the American Galvanizers Association, is defined as the process of dipping fabricated steel into a kettle or vat containing molten zinc. This process helps protect metal from corrosion. This is one of the most effective ways to protect steel and metal from rust.

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °C (842 °F).

Hot dip galvanized A193 b7 stud bolt according ASTM A153 is the most common grade of anti-rust stud bolts

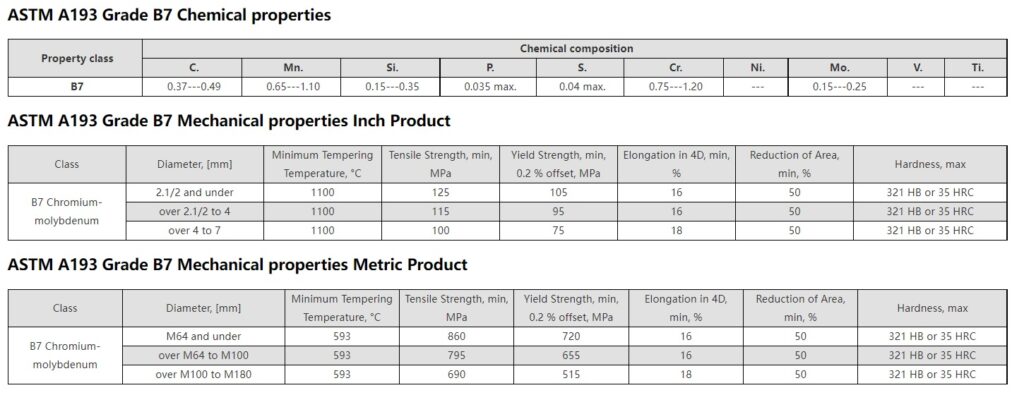

ASTM A193 Grade B7 threaded studs are manufactured from a chromium-molybdenum steel and are quenched and tempered to get the desired mechanical properties (strength). A193 Grade B7 is the most common grade of A193 bolts used in construction. A193 B7 full threaded studs bolts are commonly used in pipe flange connections. These bolts are typically bought and sold in a plain, bare metal finish but are often hot-dip galvanized, zinc plated, Xylan coated, PTFE coated, or otherwise coated for corrosion resistance. Note that coated bolts may not be able to withstand the high temperatures that uncoated B7 bolts can be subjected to.

A193 B7 stud Bolt and A194 2H nuts for pressure vessels, valves, flanges and fittings for high temperature or high pressure services, or other special purpose applications.

ASTM A193 Grade B7 Mechanical properties Inch Product

ASTM A153/A153M-16a

Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

This specification covers standards for zinc coatings applied through hot-drip process on iron and steel hardware. The hot-dip galvanizing process shall form layers of Zn/Fe alloy adhering to the steel surface. This specification is applicable to steel hardware items of Classes A, B, C, and D. The thickness or weight/mass of zinc coating shall conform to specified values for various classes of materials. The coated articles shall be free from uncoated areas, blisters, flux deposits, dross inclusions, and other defects. The coating shall be smooth and reasonably uniform in thickness. Tests shall be performed to determine the minimum coating weight or minimum coating thickness, finish and appearance, embrittlement, adherence, average weight/mass of coating, and average thickness of coating. Guidelines are also given for inspection, rejection and retest, packaging, and certification procedures.

Scope

1.1 This specification covers zinc coatings applied by the hot-dip process on iron and steel hardware. The hot-dip galvanizing process consists of parts being immersed in molten zinc for a sufficient time to allow a metallurgical reaction between iron from the steel surface and the molten zinc, resulting in the formation of Zn/Fe alloy layers bonding the coating to the steel surface.

1.2 This specification is intended to be applicable to hardware items that are centrifuged or otherwise handled to remove excess galvanizing bath metal (free zinc). Coating thickness grade requirements reflect this.

1.3 Fasteners that must comply with the Fastener Quality Act require specific statistical sampling during the inspection of the fastener lots. Requirements for the sampling of these fasteners can be found in F2329/F2329M.

ASTM F2329 / F2329M – 15

Standard Specification for Zinc Coating, Hot-Dip, Requirements for Application to Carbon and Alloy Steel Bolts, Screws, Washers, Nuts, and Special Threaded Fasteners

How to order our Hot dip galvanized A193 b7 stud bolts?

STUD BOLT, DIA X LONG,

FULLY THREADED, C/W 2 HEAVY HEXAGON NUTS,

MATL STUDBOLTS ASTM A193 GRADE B7: NUTS ASTM A194 GRADE 2H,

BOTH ITEMS TO BE HOT DIP GALVANIZED TREATED,ASTM A153 ASTM F2329

8UN THREADS TO ANSI B1.1 & TOLERANCES TO B1.1 CL 2A FOR STUDBOLTS & ANSI B18.2.2 CL 2B FOR NUTS