Hastelloy B3 Round Bar – High-Performance Corrosion-Resistant Alloy

Hastelloy B3 Round Bar is a premium nickel-molybdenum alloy known for its exceptional resistance to hydrochloric acid and other strongly reducing environments. With improved thermal stability and excellent mechanical properties, Hastelloy B3 is widely used in industries that require high corrosion resistance and durability.

UNS N10675(2.4600, NiMo29Cr) Nickel Alloy

N10675 is a nickel alloy formulated for primary forming into wrought products.

2.4600 is the EN numeric designation for this material. NiMo29Cr is the EN chemical designation. And N10675 is the UNS number.

This material is well established: the Further Reading section below cites a number of published standards, and that list is not necessarily exhaustive.

It has the lowest heat capacity among wrought nickels. In addition, it has a moderately high embodied energy and a moderately high base cost.

The graph bars on the material properties cards below compare N10675 nickel to: wrought nickels (top), all nickel alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relevant set. A half-full bar means it’s 50% of the highest, and so on

Hastelloy B3 Chemical Composition

| UNS | Element | Composition, % | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Cu | Fe | Mn | C | Si | S | Cr | Al | Ti | Nb + Ta | Mo | P | W | Co | V | N | B | La | Al + Ta | Ni + Mo | Nb | Ta | Zr | Ce | Y | Mg | ||

| UNS N10675 | Ni-Mo Alloy | 65.0 min | 0.2 | 1.0-3.0 | 3 | 0.01 | 0.1 | 0.01 | 1.0-3.0 | 0.5 | 0.2 | … | 27.0-32.0 | 0.03 | 3 | 3 | 0.2 | … | … | … | … | 94.0-98.0 | 0.2 | 0.2 | 0.1 | … | … | … |

Hastelloy B3 Mechanical Requirements

| Material and Condition | Maximum Section Thickness, in. (mm) | Tensile Strength, min, ksi (MPa) | Yield Strength, 0.2 % Offset, min, ksi (MPa) | Elongation in 2 in. or 50 mm or 4D, min, % |

|---|---|---|---|---|

| Nickel-molybdenum alloy UNS N10675, solution annealed | … | 110 (760) | 51 (350) | 40 |

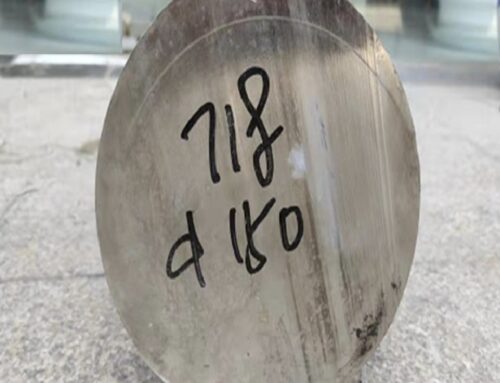

Available Sizes of Hastelloy B3 Round Bar

| Diameter (mm) | Diameter (inches) | Length |

|---|---|---|

| 6mm – 300mm | 0.25” – 12” | 1m – 6m (Custom Length Available) |

Standards & Specifications:

| Standard | Specification |

|---|---|

| ASTM | ASTM B335 |

| ASME | ASME SB335 |

| EN | EN 10204 3.1 |

| DIN | DIN 17752 / 17753 / 17754 |

Applications of UNS N10675 Round Bar:

✔ Chemical Processing – Acid reactors, heat exchangers, piping systems.

✔ Marine & Aerospace – Corrosion-resistant components.

✔ Power Plants – High-temperature and pressure applications.

✔ Pharmaceutical & Food Processing – Contamination-free production.

Why Choose Our UNS N10675 Round Bars?

🔹 High-Quality Standards – ASTM, ASME, DIN, EN compliant.

🔹 Available in Various Sizes – Custom-cut lengths & diameters.

🔹 Corrosion & Heat Resistance – Ideal for extreme environments.