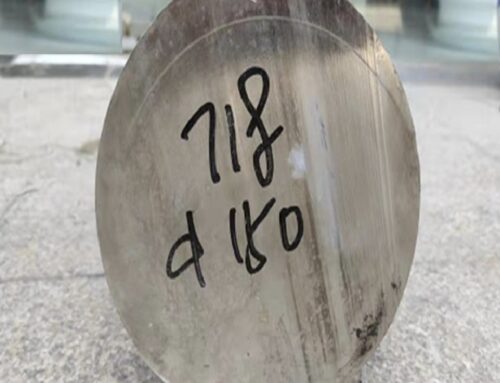

China manufacturer of Forged Ring ASTM B637 Inconel 718 Inconel UNS N07718

What is the forged ring?

Forged rings are metal rings that are made from a forging process. Forging is a manufacturing process that shapes metal by hammering, pressing, or rolling hot metal while it is in a molten state.

A forged ring is a device used to join and seal components, such as flanges, valves, or pumps. It provides an important assurance of strength and reliability.

ASTM B637 Inconel 718, also known as UNS N07718 (W.Nr. 2.4668), is a high-strength, corrosion-resistant nickel-chromium alloy designed for extreme conditions. This alloy is suitable for use in temperatures ranging from -423°F to 1300°F. It is widely used in industries such as aerospace, nuclear, and chemical processing, due to its excellent strength and resistance to oxidation and corrosion.

ASTM-B637 Standard for Inconel 718: ASTM B637 covers both hot- and cold-worked, precipitation-hardenable nickel alloy products, including rods, bars, forgings, and forging stock for moderate to high-temperature applications.

ASTM B637 Inconel 718 Composition

| Grade | chemical composition,% | |||||||

| UNS N07718 | Ni | C | Si | Mn | Cr | S | Al | Fe |

| 50.0-55.0 | ≤0.08 | ≤0.35 | ≤0.35 | 17.0-21.0 | ≤0.015 | 0.2-0.8 | Remainder | |

| Ti | Cu | Nb+Ta | Co | P | B | Mo | ||

| 0.65-1.15 | ≤0.3 | 4.75-5.5 | ≤1.0 | ≤0.015 | ≤0.006 | 2.8-3.3 | ||

Inconel 718 Equivalent grade

| Chinese | US | USA | Werkstoff Nr. |

| GH4169/GH169 | UNS NO7718 | Inconel 718 | 2.4668 |

N07718 Mechanical Properties (solution + precipitation harden)

| Tensile Strength Rm (Mpa) | Yield Strength Rp0.2 (Mpa) | Elongation % in 2″ (50.8 mm) | Reduction Of Area (%) | Hardness (HBW) |

|---|---|---|---|---|

| 1275 min | 1034 min | 6 min | 8 min | 331 min |

Standard Specifications for Inconel 718 Forged Rings

Inconel 718 forged rings are manufactured according to the following international standards:

| Standard | Description |

|---|---|

| ASTM B637 | Standard Specification for Precipitation-Hardening Nickel Alloys |

| AMS 5662, AMS 5663, AMS 5664 | Aerospace Material Specification |

| UNS N07718 | Unified Numbering System for Nickel Alloys |

| API 6A | Suitable for oil & gas applications |

| NACE MR0175/ISO 15156 | Corrosion-resistant material for sour gas environments |

Manufacturing Process of N07718 Forged Rings

The forging process includes:

- Billet Selection: High-purity Inconel 718 material is used.

- Heating: Heated to 1100 – 1150°C before forging.

- Open Die Forging: Compressed and shaped into rings using hydraulic presses.

- Heat Treatment: Solution annealing & aging treatments to enhance strength.

- Machining & Surface Finish: Precision machining to achieve desired dimensions.

- Non-Destructive Testing (NDT): Includes ultrasonic testing (UT), magnetic particle inspection (MPI), and X-ray testing to ensure quality.

Heat Treatment Process

Inconel 718 forged rings undergo the following heat treatments to optimize their mechanical properties:

- Solution Annealing: 980 – 1010°C (1800 – 1850°F) followed by rapid cooling.

- Aging Treatment:

- First stage: 720°C (1328°F) for 8 hours, then cooled to 620°C (1150°F).

- Second stage: Holding at 620°C for 8 hours, followed by air cooling.

This enhances precipitation hardening, improving strength and durability.

Inconel 718 Forged Rings provide unmatched strength, corrosion resistance, and durability for high-performance industries like aerospace, oil & gas, and power generation.Pls do not hesitate to drop a mail for any enquiries.