Flange Insulation Kit ASME B16.5 Insulation Gasket Kit – Type E

China manufacturer and exporter of Flange Insulation Kit ASME B16.5 Insulation Gasket Kit – Type E

Flange Isolation Gasket Kits are manufactured according to ANSI B16.5 specifications up to 24″.

Gasket sets for flange insulation are designed to ensure the integrity and reliability of the pipeline and piping system through safety and corrosion protection. By eliminating metal-to-metal contact, static flow is stopped to prevent corrosion and aid in the cathodic protection of the piping system.

Flange insulation gasket kits provide both effective sealing and reliable electrical insulation of flanges. Made of high-quality materials with high dielectric constant and low water absorption. Flange insulation gaskets kits are available in different configurations to meet any possible need. Flange insulation gasket kits come in all DIN, ASME and API classes.

Flange Insulation kits can be used in the petrochemical, oil refinery, offshore seawater environments, where the transfer of volatile fluids through the pipeline can create explosive conditions which could be ignited by stray electrical currents.

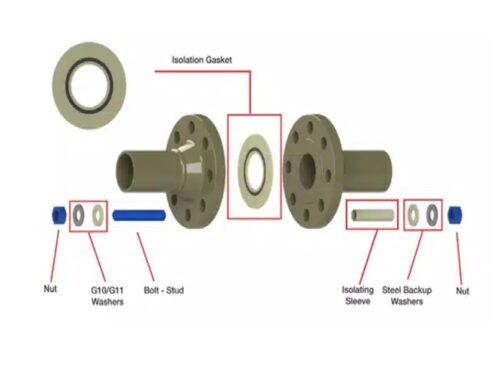

Each flange insulation set comprises one central flat or oval section gasket, plus one insulation sleeve, two insulating and two plated steel washers per bolt. The sets are individually packed and clearly labelled with the flange rating, size, type and material combination.

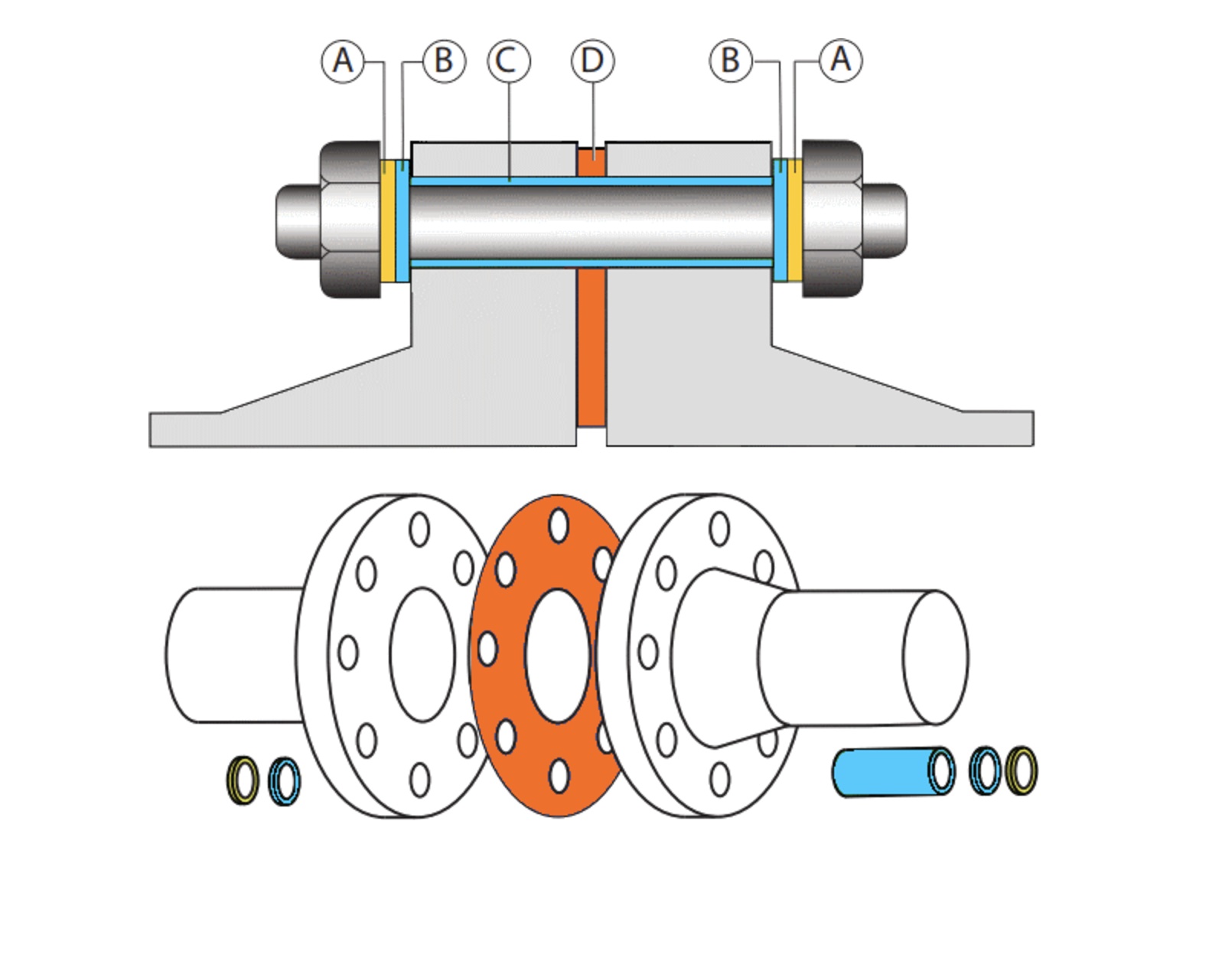

Components of a Flange Isolation Kit

A typical flange isolation kit includes:

- Isolation Gasket:

- Types: Full-face, ring-type, or specific designs like the API RTJ.

- Materials: Phenolic, PTFE (Teflon), G10/G11 (fiberglass-reinforced epoxy), or high-temperature options like mica or spiral-wound designs.

- Isolation Sleeves:

- Insulate the bolts from the flange.

- Made of non-conductive materials like Mylar, G10, or Nomex.

- Isolation Washers:

- Two per bolt (one insulating, one metallic for load distribution).

- Materials: Nylon, phenolic, or G10.

- Metallic Washers:

Types of Flange Isolation Kits

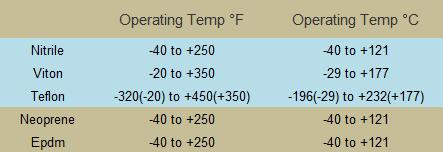

Type E:

a full-faced gasket with the same outside diameter as the flange and precision cut bolt holes. This design facilitates proper alignment of the gasket during installation and foreign material prevented from shorting the flange insulation. The type E gaskets are available in plain face or Neoprene face phenolic, as well as a variety of high temperature materials.

We supply flange insulation gasket kits like Type F gaskets, Type E gaskets and Type D (API Ring Joint) gaskets.

Type E Flange Insulation Gasket (FULL FACE)

Type E Flange insulation Gasket Kit is designed for whole safety of flanges and have the exact same outside size as the flange. Each one insulation gasket features accuracy machined bolt holes. On assembly, it is recommended that sealing tape be wrapped surrounding the outside of the particular flange to counteract external material from lodging between the totally exposed portions and triggering shorting out of the flanges. Almost all Type E gaskets are easily centered with all the flange inside diameter. Gaskets with slightly much larger outside diameters are accessible on demand. Type E gaskets are available in G10, G11, G7, Neoprene or Nitrile Faced Phenolic, Plain Phenolic, and G10 with stainless steel 316 core or Non-asbestos materials.

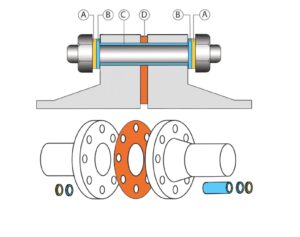

Type E

A 3,2 mm (1/8 inch) thick plated steel washer

B 3,2 mm (1/8 inch) thick insulating washer

C Full length insulating sleeve

D Full face Gasket

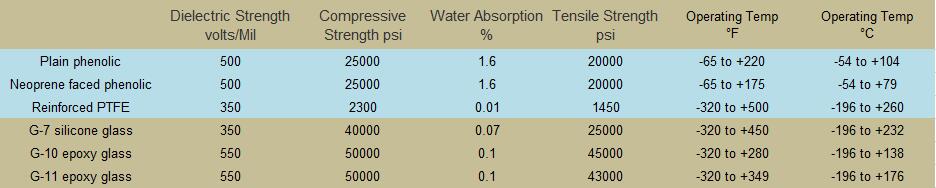

Gasket Material

Seal Material

| Isolating Sleeve G7 G10 G11 Mylar NOMEX Isolating Washers Steel Washer |