Ceramic Filled Coating Stud Bolt Xylar 2 +Xylar 101 coated stud bolt

China manufacturer of Ceramic Filled Metal Coating Stud Bolt Xylar 2 +Xylar 101 coated stud bolt

Ceramic coating is a chemical polymer solution that is applied to the exterior on the stud bolts,Ceramic coating is normally used where high temperature application is required

Ceramic-filled coatings are advanced protective materials that incorporate fine ceramic particles into a polymer-based binder.

Xylar 2 is the most common ceramic coating on the stus bolts

Xylar 2 is an inorganic ceramic-metallic coating which was originally designed to provide the aerospace and marine industries with a product that would protect components from galvanic corrosion, high temperature, oxidisation, salt laden atmospheres, chemicals and abrasives.

Xylar 2 is an inorganic ceramic-metallic basecoat and can be used with or without a Xylan topcoat. It can last for more than 5000 hours when combined with a Xylan topcoat.

Due to its thin film build and extremely high corrosion resistant properties, Xylar 2 is of particularly great use as a primer for Xylan topcoats on fasteners, threaded components and other low tolerance applications. Excellent heat resistance (up to 650⁰C) makes it an ideal solution for engine applications where the electrical couple between dissimilar metals could result in corrosion.

Xylar 2 is also an extraordinarily hard coating that provides barrier shield against abrasive wear in applications involving coarse slurries, cavitation and stone pecking.

Xylar2 normally applied as the primer coating on the stud bolts.we may have either Xylar 101 or PTFE coating on the top

Benefit of Ceramic Filled metal Coating

Corrosion Resistance:

- XYLAR 2 offers superior resistance to a wide range of aggressive chemicals, including acids, alkalis, solvents, and other corrosive substances.

- Ideal for environments where components are exposed to harsh chemicals, such as in the chemical processing, petrochemical, and pharmaceutical industries.

High-Temperature Resistance:

- The coating can withstand temperatures up to 500°F (260°C) without degradation, making it suitable for use in high-temperature environments like power generation and refineries.

Low Friction:

- XYLAR 2 provides excellent low-friction properties, which reduce wear on coated components, especially in applications involving frequent assembly and disassembly (e.g., fasteners, valves).

- The low friction properties also help prevent galling, which is the sticking or seizing of threads between fasteners under pressure.

Electrical Insulation:

- As a PTFE-based coating, XYLAR 2 also provides good electrical insulation, which can be useful in applications where conductivity needs to be minimized or avoided.

Smooth Surface:

- The coating creates a smooth, slick surface that reduces friction and helps components slide or move with minimal resistance. This smoothness also makes XYLAR 2-coated components easier to clean.

Xylar 101 is a sealer/topcoat that enhances the corrosion resistance of Xylar 2. It is a dense, clear film that fills any surface pores on Xylar 2

We can also make the top PTFE coating over the base Xylar Ceramic coating on the stud bolt

Xylar 2 / Xylan 1070 PTFE coated stud bolts

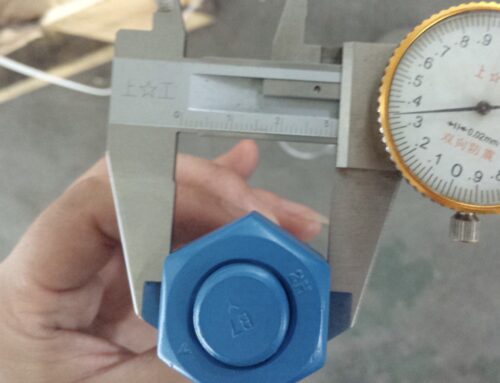

Xylar 2 / Xylar 101 coated stud bolts

Xylar 2 xylar 101 coated ASTM A193 B7 Stud bolt

Xylar 2 xylar 101 coated ASTM A193 B7M Stud bolt

Xylar 2 xylar 101 coated ASTM A193 B16 Stud bolt

Xylar 2 +Xylar 101 coated Stud Bolt order specification

STUD BOLT, DIA X LONG,

FULLY THREADED, C/W 2 HEAVY HEXAGON NUTS,

MATL STUDBOLTS ASTM A193 GRADE B7: NUTS ASTM A194 GRADE 2H,

Xylar 2 +Xylar 101 coated.