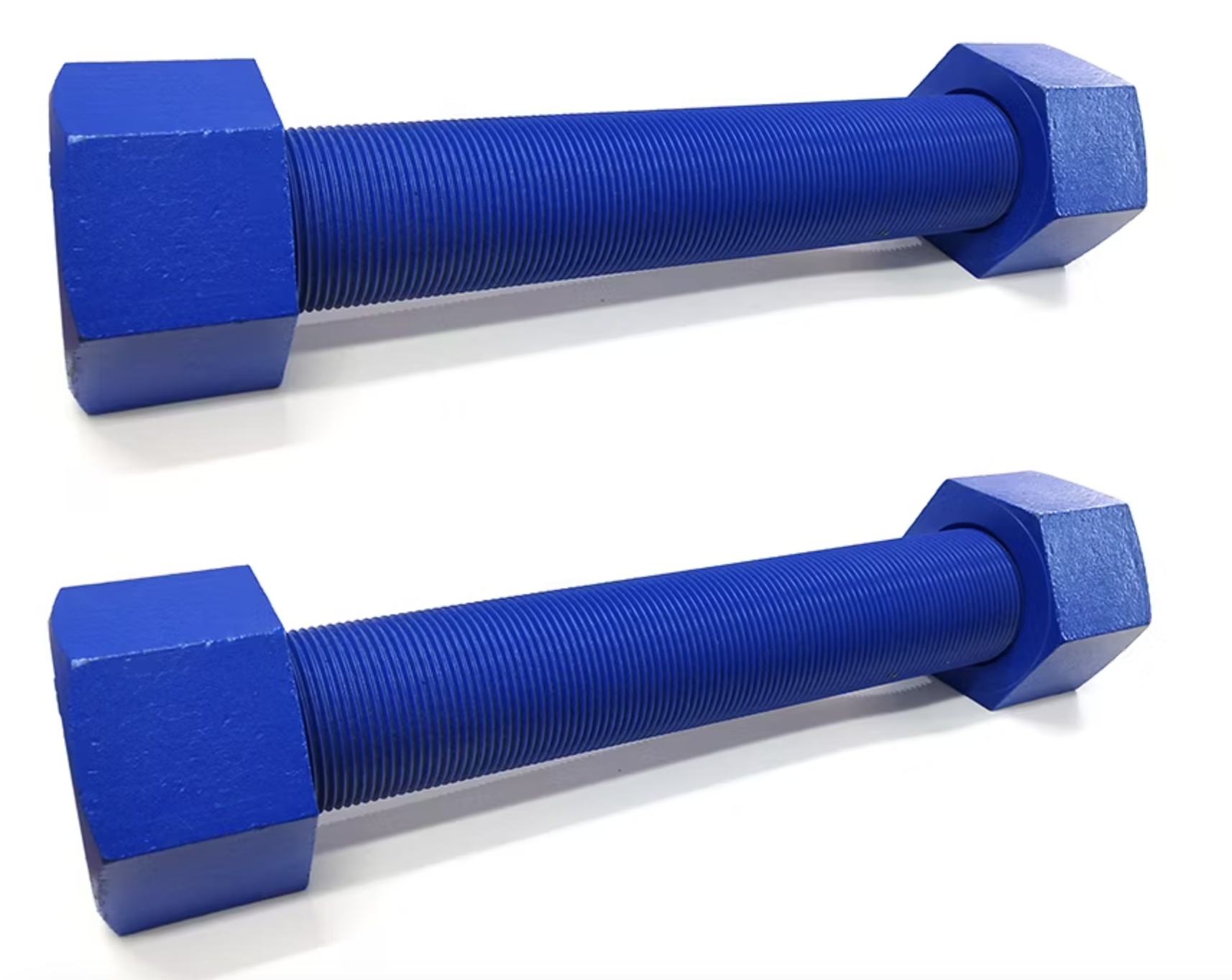

ASTM A193 Grade B7 Stud bolt

ASTM A193 Grade B7 is a standard specification for high tensile alloy steel bolting material for use in high temperature or high-pressure service and other special purpose applications. It covers material specification for bolting used in pressure vessel service, valves, flanges and fittings.

ASTM A193

Standard Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other Special Purpose Applications

ASTM A193 Grade B7 stud bolts are high strength fasteners manufactured from a chromium-molybdenum steel and are quenched and tempered.

ASTM A193 B7 Heat Treatment

A193 B7 and B7M shall be heat treated by quenching in a liquid medium and tempering. For B7M fasteners, the final heat treatment, which may be the tempering operation if conducted at 1150 °F [620 °C] minimum, shall be done after all machining and forming operations, including thread rolling and any type of cutting. Surface preparation for hardness testing, nondestructive evaluation, or ultrasonic bolt tensioning is permitted.

Unless otherwise specified, material for Grade B7 may be heat treated by the Furnace, the Induction or the Electrical Resistance method.

ASTM A193 B7 Stud Bolt Manufacture (Process)

The steel shall be produced by any of the following processes: open-hearth, basic-oxygen, electric-furnace, or vacuum-induction melting (VIM). The molten steel may be vacuum-treated prior to or during pouring of the ingot or strand casting. 5.2 Quality—See Specification A962/A962M for requirements

ASTM A193 B7 Chemical Composition

Each alloy shall conform to the chemical composition requirements prescribed in Table 1. 8.2 The steel shall not contain an unspecified element for the ordered grade to the extent that the steel conforms to the requirements of another grade for which that element is a specified element. Furthermore, elements present in concentrations greater than 0.75 weight/% shall be reported.

| C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.37-0.49 | 0.65-1.10 | 0.15-0.35 | 0.035 | 0.04 | 0.75-1.20 | 0.15-0.25 |

A193 B7 Stud Bolt Mechanical Properties

A193 B7 Hardness Requirements:

B7 stud bolt should have the harndesss Max 321 HB or 35 HRC

Hex nuts for A193 B7 Stud bolt

Bolts, studs, and stud bolts shall be furnished with nuts, when specified in the purchase order.

Nuts shall conform to Specification A194/A194M

Normally A193 B7 Stud bolts are supplied with A194 grade 2H Hex nuts

A193 B7 Stud bolt Certification

The producer of the raw material or finished fasteners shall furnish a certification to the purchaser or his representative showing the results of the chemical analysis, macroetch examination (Carbon and Alloy Steels Only), and mechanical tests, and state the method of heat treatment employed.

Certification shall also include at least the following:

A statement that the material or the fasteners, or both, were manufactured, sampled, tested, and inspected in accordance with the specification and any supplementary requirements or other requirements designated in the purchase order or contract and was found to meet those requirements.

ASTM A193 Grade B7 stud bolt is the most widely fasteners, commonly found in bolting or piping, pressure vessels, valves, flanges and fittings.

We can provide theASTM A193 B7 Bolt with 2 ASTM A194 2H nuts,with following different surface treatments

-

- Plating

- Zinc (White / Yellow / Black)

- Cadmium (White / Yellow / Black)

- Zinc Nickel

- ZINC PLATED/BICHROMATE TREATED

- Plating

-

- Galvanising

- Hot-Dipped Galvanise

- Mechanical Galvanise

- Galvanising

-

- Fluorocarbon Coating

Xylan® / Dupont Coating Systems:- Xylar 2

- Xylan 1070 Coated ASTM A193 Grade B7 Stud bolt Xylan 1070 blue coating is the most popular PTFE coating for the stud bot

- Ceramic Fluoropolymer Coated stud bolt

- Xylan 1424 Coated ASTM A193 Grade B7 Stud bolt

- Fluorocarbon Coating

- Customised Coating Systems

- Zinc + Fluorocarbon / PTFE coated stud bolt A193 B7

- Cadmium + Fluorocarbon /PTFE coated stud bolt A193 B7

- Zinc Nickel + Fluorocarbon /PTFE coated stud bolt A193 B7

- Zinc Plating + Xylan 1424 Blue PTFE coated stud bolt A193 B7

- Xylar 2 + Xylan 1070 coated stud bolt A193 B7

- stud bolt ZINC PLATED/BICHROMATE TREATED

- Zinc Yellow Bichromated