ASTM B564 Inconel 600 N06600 Forged round Disc Manufacturer and exporter in China

INCONEL® (nickel-chromium-iron) alloy 600 (UNS N06600/W.Nr. 2.4816) is a standard engineering material for applications which require resistance to corrosion.

Alloy 600 / Inconel 600 is combination of Nickel Chromium and Iron providing a standard material for the chemical industry and the automotive engine, aero engine and airframe sectors. Controlled chemical composition limits are applied in the nuclear industry to eliminate the risk of stress corrosion cracking by high purity water containing chloride ions.

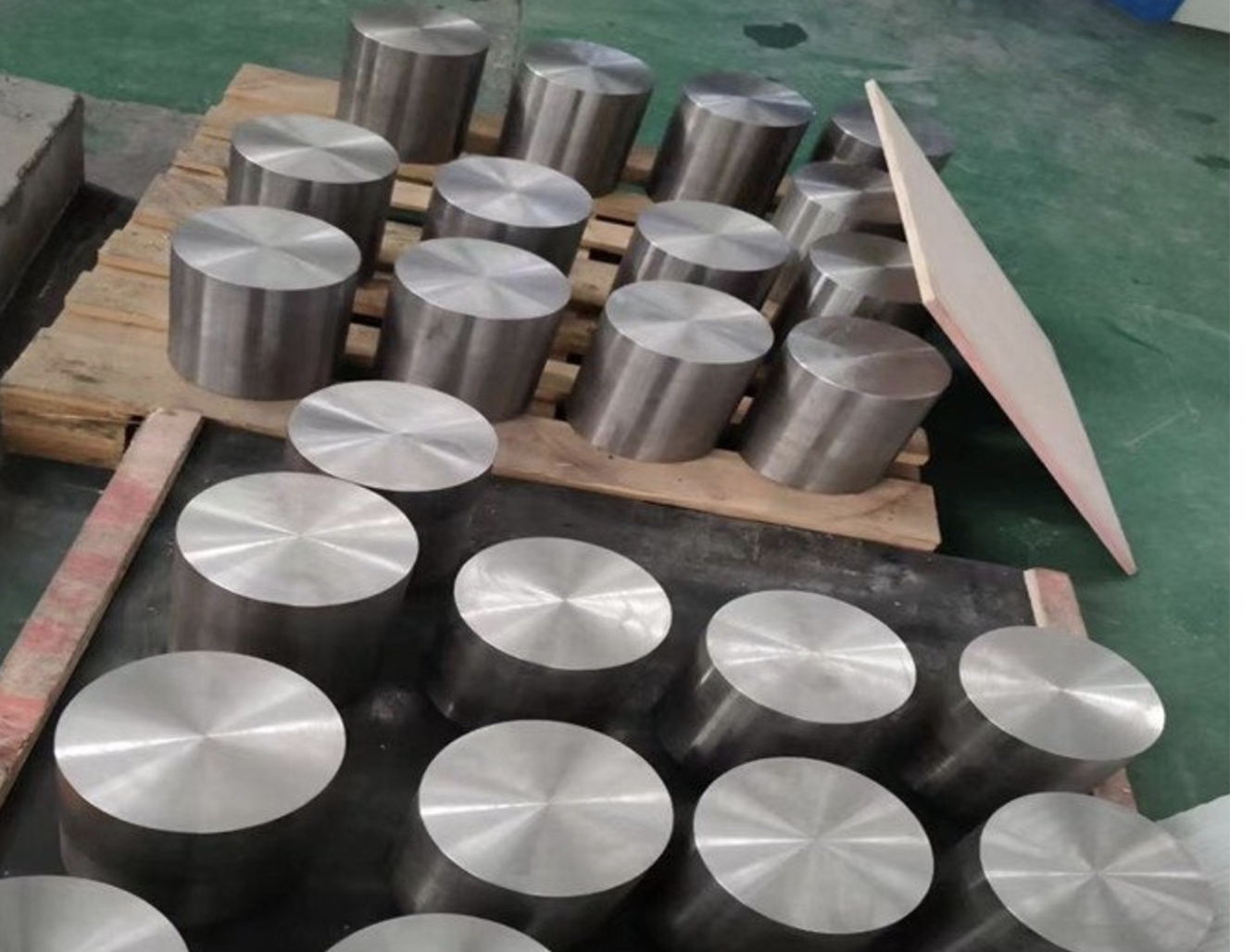

A round disc made from N06600 (commonly known as Inconel 600) is a circular component forged, machined, or cut from a nickel-based alloy.

Forged round Disc

A forged round disc is a circular-shaped component manufactured using the forging process, which involves compressing and shaping metal under high pressure to achieve improved mechanical properties.

| Product name | Forging Disc,round disc | |||

| Dimension | delivery with thickness 8mm and 10mm Discs with step are usually supplied with thickness: 12mm; 13.5mm; 14mm; 15mm; 16mm; 18mm; 20mm; 22mm; 25mm Every dimension above mentioned (diameters and thickness) could be supplied as per Customer’s requirements. | |||

Chemical composition of N06600

| Composition | UNS N06600 composition, % |

| Carbon | 0.15 max |

| Manganese | 1.00 max |

| Sulfur | 0.015 max |

| Silicon | 0.50 max |

| Chromium | 14.00 – 17.00 |

| Iron | 6.00 – 10.00 |

| Copper | 0.50 max |

| Nickel + Cobalt | 72.00 min |

Inconel 600 Nickel alloy and Super Alloy Steel Grade Forging Disc

Inconel 600 Mechanical Requirements

| Material and Condition | Maximum Section Thickness, in. (mm) | Tensile Strength, min, ksi (MPa) | Yield Strength, 0.2 % Offset, min, ksi (MPa) | Elongation in 2 in. or 50 mm or 4D, min, % |

|---|---|---|---|---|

| Nickel-chromium-iron alloy UNS N06600, annealed | … | 80 (552) | 35 (241) | 30 |

Applications of N06600 Round Discs:

- Aerospace:

- Jet engine components and gas turbines.

- Chemical Processing:

- Heat exchangers, evaporators, and reactors.

- Power Generation:

- Components in nuclear and fossil fuel power plants.

- Marine:

- Seawater applications requiring resistance to pitting and crevice corrosion.