China Manufacturer of ASTM B166 Inconel 601 Round Bar N06601 Rod

What is Inconel 601?

Inconel 601 is a nickel-chromium alloy, that is highly resistant to oxidation through 2200°F. Inconel 601 is a nickel-chromium alloy used for applications that require resistance to corrosion and heat.

Inconel 601 is also known as N06601, The outstanding characteristic of Inconel 601 is its resistance to high-temperature oxidation. The alloy also has good resistance to aqueous corrosion, has high mechanical strength, and is readily formed, machined, and welded.

The Composition (%) of Nickel Inconel 601

The composition of the particular alloy is the following:

| Nickel | Chromium | Iron | Aluminum | Carbon | Manganese | Sulfur | Silicon | Copper |

| 58%-63% | 21%-25% | Remainder | 1%-1.7% | 0.10% max | 1% max | 0.015% max | 0.50% max | 1% max |

Mechanical and Physical Properties of Nickel Inconel 601

Nickel Inconel 601 has good mechanical strength, but its mechanical property changes depending on the form of the material. According to the manufacturer, the optimal temperature for this alloy is 1004°F (540°C) and above for solution-treated condition, and 1004°F (540°C) and below for annealed condition. Being used primarily in high-temperature applications, the Inconel Alloy 601 can retain its high tensile properties at higher temperatures, and it is not embrittled by extended exposure.

| Mechanical Properties | Imperial | Metric |

| Tensile strength (solution annealed, room temperature) | 110000 psi | 760 MPa |

| Yield strength (solution annealed, room temperature) | 65300 psi | 450 MPa |

| Elongation at break | 42% | 42% |

About ASTM B166

Standard Specification for Nickel-Chromium-Aluminum Alloy, Nickel-Chromium-Iron Alloys, Nickel-Chromium-Cobalt-Molybdenum Alloy, Nickel-Iron-Chromium-Tungsten Alloy, and Nickel-Chromium-Molybdenum-Copper Alloy Rod, Bar, and Wire

This specification covers nickel-chromium-iron alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) and nickel-chromium-cobaltmolybdenum alloy (UNS N06617) in the form of hot-finished and cold-worked rounds, squares, hexagons, rectangles, and cold-worked wire. The material shall conform to the composition limits specified in a reference material. The material shall be uniform in quality and condition, smooth, commercially straight or flat, and free of injurious imperfections. Mechanical properties of the alloys like tensile strength, yield strength, elongation, and hardness shall be determined by tension and hardness tests.

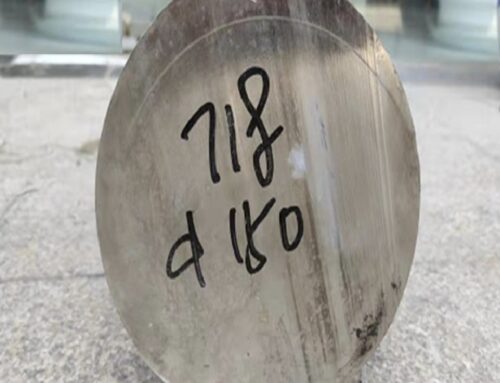

ASTM B166 Inconel 601 Round Bar Specifiction

- Size Range of N06601 round bar

- Diameter:

- Cold Drawn: 4 mm to 100 mm (0.16″ to 3.94″).

- Hot Rolled/Forged: 100 mm to 500 mm (3.94″ to 19.69″).

- Larger diameters may be available upon request.

- Length:

- Standard: 3 meters to 6 meters (10 ft to 20 ft).

- Cut-to-size lengths available based on requirements.

- Material grade:ASTM B166 Inconel 601

Standards & Testing:

- Manufacturing Standards: ASTM B166.

- Testing: Mechanical property tests (tensile, yield, elongation), hardness, and chemical composition analysis.

- Heat Treatment: Typically annealed for enhanced performance.

Applications and Common Use Of Nickel Inconel 601 Round bar

- High-temperature applications in the automotive industry and aerospace – turbocharger rotors and seals (notable use is Mazda RX-7 third gen), rotary engines (Norton motorcycles), Formula 1 and NASCAR exhaust systems;

- High-temperature applications in aerospace – gas turbine blades and containment rings, seals and combustors, jet engine igniters, combustion-can liners, and diffuser assembles;

- Thermal-processing equipment – baskets, trays, and fixtures for annealing, carburizing, carbonitriding, nitriding for industrial-heating applications, and in radiant tubes, muffles, retorts, flame shields, strand-annealing tubes, woven-wire conveyor belts, and electrical resistance heating elements in industrial furnaces;

- Chemical-processing – insulating cans in ammonia reformers and equipment for nitric acid production;

- Petrochemical processing – catalyst generators and air preheaters;

- Pollution-control applications – combustion chambers in solid-waste incinerators;

- Power-generation field – superheater tube supports grid barriers and ash handling

ASTM B166 covers nickel-chromium-iron alloy bars, rods, and wires. Inconel 601 is particularly known for its resistance to high-temperature oxidation and corrosion, as well as excellent mechanical properties.