ASTM A479 UNS S31254 254SMO F44 Round Bar

China manufacturer of ASTM A479 UNS S31254 254SMO F44 Round Bar.

254SMO Round Bar is a round bar made of Stainless ASTM A479 UNS S31254.

Stainless steel grade 254 SMO™ is a very high end austenitic stainless steel. It is designed with a combination of impact toughness resistance to chloride stress corrosion cracking, and pitting and crevice corrosion with strength that is twice that of the stainless steel 300 series.

For certain applications, grade 254 SMO™ has been reported to be a cost-effective substitute for high nickel and titanium alloys. It is known to possess excellent workability as well.

ASTM A479

Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels

This specification covers hot- and cold-finished bars of stainless steel, including rounds, squares, and hexagons, and hot-rolled or extruded shapes such as angles, tees, and channels for use in boiler and pressure vessel construction. Four grades of the stainless steel are available which includes austenitic, austenitic-ferritic, ferritic, and martensitic grades. Mechanical properties such as tensile strength, yield strength, elongation, and hardness shall be determined for the specimens subjected to normalized, tempered, annealed, and quenched conditions. The austenitic stainless steels shall be subjected to heat treatment and shall undergo corrosion test.

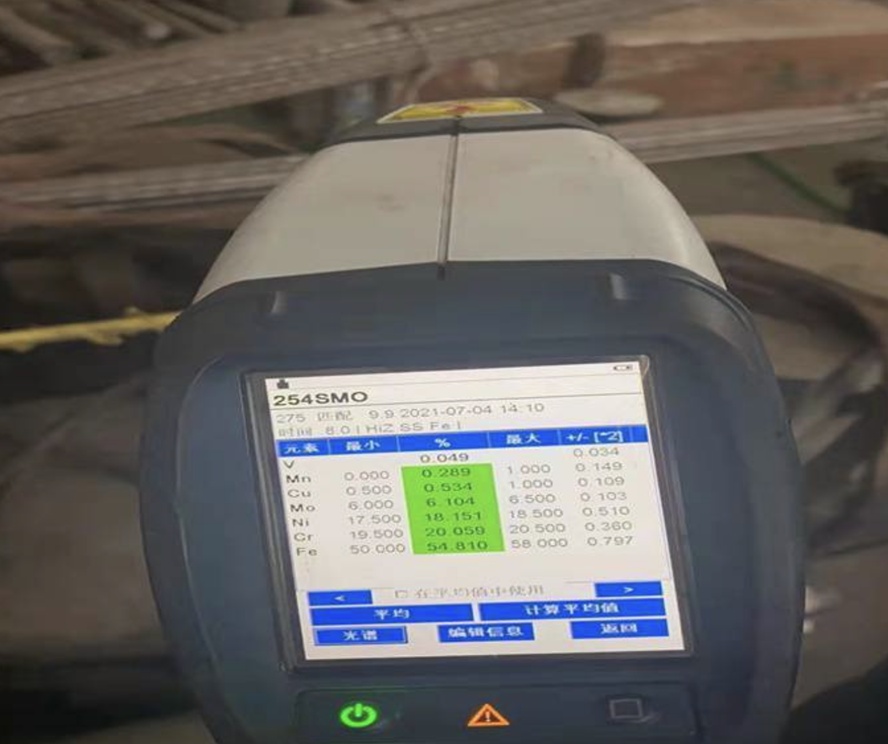

254SMO Chemical Composition

| Element | Austenitic Stainless Steel |

|---|---|

| UNS S31254 / Alloy 254SMO / 1.4547 | |

| CompositionA, % | |

| Carbon | 0.02 max |

| Manganese | 1.00 |

| Phosphorus | 0.030 max |

| Sulfur | 0.010 max |

| Silicon | 0.80 max |

| Chromium | 19.50 – 20.50 |

| Nickel | 17.50 – 18.50 |

| Molybdenum | 6.00 – 6.50 |

| Nitrogen | 0.18 – 0.22 |

| Copper | 0.50 – 1.00 |

AThe intentional addition of Bi, Se, Te, and Pb is not permitted.

254SMO IS A KIND OF SUPER AUSTENITIC STAINLESS STEEL WITH HIGH CORROSION RESISTANCE. IT IS DEVELOPED FOR HALIDE AND ACID ENVIRONMENTS AND IS WIDELY USED IN HARSH ENVIRONMENTS SUCH AS HIGH CONCENTRATION CHLORIDE ION MEDIA AND SEAWATER. IN VARIOUS INDUSTRIAL OCCASIONS IN ACIDIC MEDIA, ESPECIALLY IN ACIDS CONTAINING HALIDES, 254SMO IS FAR SUPERIOR TO OTHER STAINLESS STEELS, AND IN SOME CASES COMPARABLE TO HASTELLOY AND TITANIUM. LOW CARBON CONTENT AND HIGH MOLYBDENUM CONTENT MAKE IT HAVE BETTER RESISTANCE TO PITTING CORROSION AND CREVICE CORROSION, AND EXCELLENT RESISTANCE TO INTERGRANULAR CORROSION. WIDELY USED.

ASTM A479 UNS S31254 Round bar Mechanical Properties

| Grade | SMO 254 |

|---|---|

| Yield Strength (0.2%Offset) | 300 |

| Tensile Strength | 650 |

| Density | 8.0 g/cm3 |

| Elongation | 35% |

| Melting Point | 1320-1390°C |

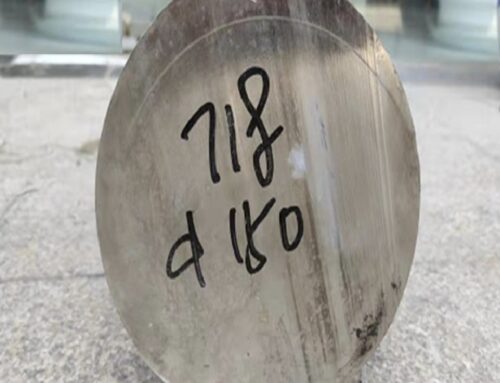

ASTM A479 round bar size

-

OD: 4mm to 500mm

Length

-

1 to 6 Meters

-

Custom Cut Lengths

Alloy S31254 (254 SMO) is widely used in chemical processing, marine applications, and oil & gas industries, thanks to its resilience in harsh environments, particularly in saltwater and sulfuric acid conditions