China ASTM A453 Gr 660 Stud Bolt Manufacturer and exporter

ASTM A453 Grade 600, 651, 662, 665 & 668 in various tensile class.

We produce these fasteners from 3/8″ to 4″ in imperial and upto M100 in metric sizes. Larger size bolts can be made to order as per request. We also undertake custom made boltings in A453 as per drawing.

ASTM A453 Standard Specification for High-Temperature Bolting Materials, with Expansion Coefficients Comparable to Austenitic Stainless Steels

| Standard: | ANSI/ASME B 18.31.2,DIN975/DIN976 |

| Diameter: | 1/4″-5″,M6-M125 |

| Length: | ≤9m or 30feet |

| Material: | ASTM A453 Grade 600, 651, 662, 665 & 668 in various tensile class. |

ASTM A453 Gr 660 Stud Bolt Ordering Information

The inquiry and order shall indicate the following:

1.1 Quantity (weight or number of pieces),

1.2 Description of material (bars, bolts, nuts, etc.),

1.3 Grade and class (see Table 3),

1.4 Method of finishing (see 6.1),

1.5 Type of thread desired (see 6.1.1),

1.6 Alternative test method option (see 7.2.4.3),

1.7 Bolt shape option, if any,

1.8 Thread option, if any,

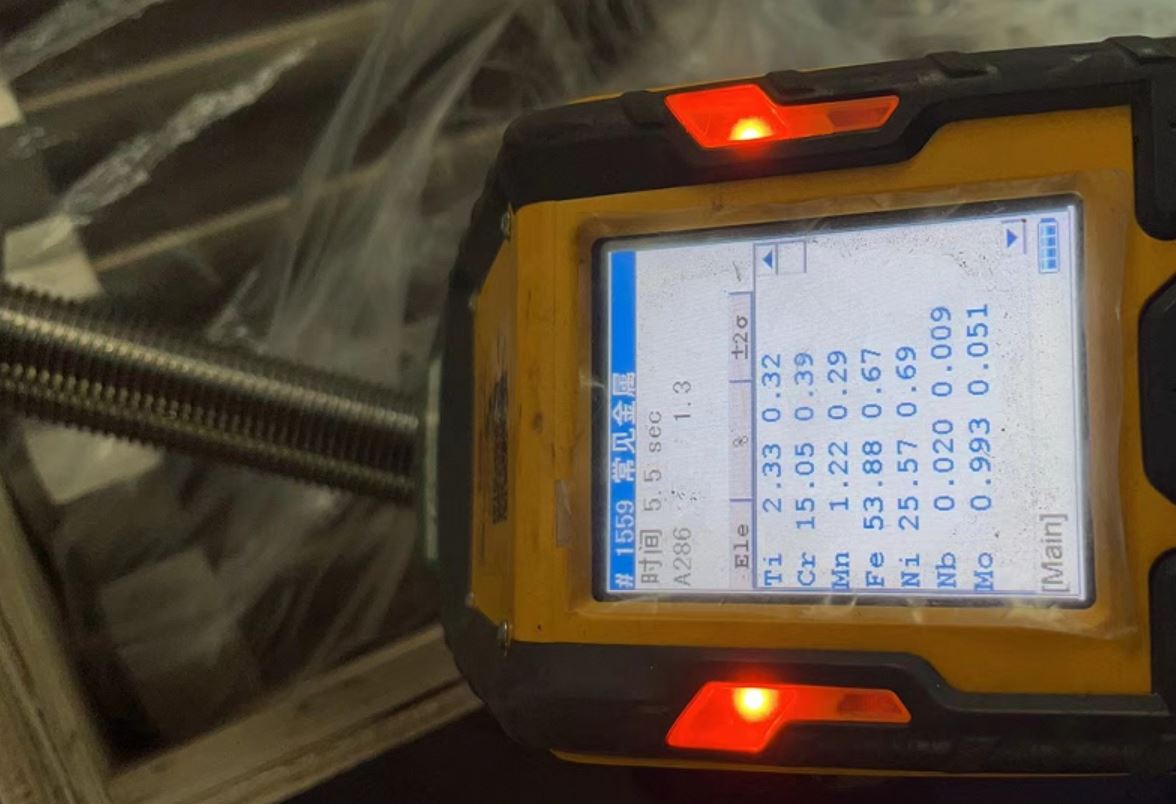

Chemical Composition of A453 grade 660 stud bolt

ASTM A453 Gr 660 Stud Bolt Finishing Process:

Threads may be performed by machining or rolling. For Type 1 bolting, threading shall be performed after precipitation

heat treatment. Types M1 and M2 bolting shall have machine cut threads. For Types 2 R1 and R2, bolting shall have rolled threads.

Types R1 and M1 bolting, threading shall be performed after precipitation heat treatment. Types R2 and M2 bolting shall be

threaded after solution heat treatment but prior to precipitation heat treatment. When not specified by the purchaser, the type

supplied shall be the option of the manufacturer.

ASTM A453 Gr 660 Stud Bolt Materials and Manufacture

—Each grade and class shall be heat treated as prescribed in Table 4.

ASTM A453 Gr 660 Stud Bolt Mechanical Properties

Tension Test:

Requirements—The material in each heat-treatment charge shall conform to the room-temperature tensile requirements in

Table 5.

Number of Specimens:

Heat-Treated Bars—When not more than two sizes of bars are heat treated in the same load, one tension test shall be

made from each size in each heat of material in the heat-treatment charge (see 3.1.2). When more than two sizes of bars are treated

in the same charge, one tension test shall be made from one bar of each of the two largest diameters from each heat of material

in the heat-treating charge.

Finished Parts—One tension test shall be made if the lot consists of parts of the same nominal diameter. If the lot

consists of parts of more than one nominal diameter, one tension test shall be made from each nominal diameter of each heat

involved in the lot (see Section 3).

The diameter range shall be in increments of 1⁄2 in. [12.5 mm].

Stress-Rupture Test:

Requirements—The material shall conform to the stress-rupture requirements prescribed in Table 6 for design

temperatures above 800 °F [427 °C]. Material not stress-rupture tested shall be permanently stamped NR. Grade 660 Class D does not require stress-rupture and shall be stamped NR.

The number of specimens shall be the same as the required number of tension test specimens.

The test location and orientation shall be the same as that required for the tension test specimens.

Test Method:

The rupture test shall be performed in accordance with Practice E 139

ASTM A453 Gr 660 Stud Bolt Hardness Test:

Requirements—The material shall conform to the

room temperature hardness requirements prescribed in Table 5.

For Grade 660 Class D, in the case of conflict, tensile test results shall prevail over minimum hardness.

A453 Stud bolt Product Marking

Bolts, Nuts, Screws, Studs, and Steel Bolts—In addition

to the grade and class shown in Table 4, the type designation

(see 6.1.1) shall also appear on all bolting material so processed. Grade 660 Class D shall be stamped NR in addition to

other required markings

Referenced Documents

ASTM Standards:

A193/A193M Specification for Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service Specification

for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other Special Purpose

Applications

A437/A437M Specification for Stainless and Alloy-Steel Turbine-Type Bolting Material Specially Heat Treated for HighTemperature Service

A962/A962M Specification for Common Requirements for Steel Fasteners or Fastener Materials, or Both,Bolting Intended for

Use at Any Temperature from Cryogenic to the Creep Range

E139 Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

F1470 GuidePractice for Fastener Sampling for Specified Mechanical Properties and Performance Inspection