We are a professional manufacturer of ASTM A193 B7M SA193 B7M Stud bolts with 2HM Hex Nuts in China

ASTM A193 Grade B7M is a standard material specification for chromium-molybdenum alloy steel fasteners for use in high tensile, high temperature and special purpose applications

Grade B7M is a heat-treated chromium-molybdenum alloy steel with minimum tensile requirement of 100 ksi, yield of 75 ksi and maximum hardness of 99 HRB. ASTM A193 specification covers requirements for chemical composition, mechanical properties, hardness, heat-treatment, recommended nuts-washrs for Grade B7M fasteners. The difference between B7 & B7M is the hardness testing requirement for each bolt from a given lot in the latter.

ASTM A193 B7M Stud Bolt

An ASTM A193 B7M stud bolt is a high-strength fastener made from a chromium-molybdenum steel alloy, designed specifically for use in environments for hydrogen sulfide (H₂S) or sour service

1. Chemical Composition

The chemical composition of A193 B7M is the same as A193 B7, which is based on chromium-molybdenum steel.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.37–0.49 |

| Manganese (Mn) | 0.65–1.10 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

| Silicon (Si) | 0.15–0.35 |

| Chromium (Cr) | 0.80–1.20 |

| Molybdenum (Mo) | 0.15–0.25 |

2. Mechanical Properties

| Property | ASTM A193 B7 | ASTM A193 B7M |

|---|---|---|

| Tensile Strength | Min. 125 ksi (860 MPa) | Max. 100 ksi (690 MPa) |

| Yield Strength | Min. 105 ksi (725 MPa) | Min. 75 ksi (515 MPa) |

| Hardness | Max. 35 HRC | Max. 22 HRC |

- B7M bolts have reduced tensile strength and hardness to improve ductility and reduce the risk of SCC in sour service environments.

3. Heat Treatment

- Quenched and tempered to achieve the required mechanical properties.

- Heat treatment is carefully controlled to meet the reduced hardness and strength requirements of B7M.

4. Applications

ASTM A193 B7M stud bolts are specifically designed for:

- Sour Gas Service:

- Environments with H₂S (hydrogen sulfide), which is highly corrosive and can cause stress corrosion cracking.

- Oil & Gas Industry:

- Offshore drilling, refineries, and pipelines.

- Chemical Processing:

- High-temperature, high-pressure systems exposed to corrosive media.

- Petrochemical Plants:

- Heat exchangers, reactors, and pressure vessels.

5. Compliance with NACE MR0175

ASTM A193 B7M is often manufactured to comply with NACE MR0175/ISO 15156, which specifies materials for sour gas environments to prevent sulfide stress cracking.

- Why B7M for Sour Service?

- Lower hardness (≤ 22 HRC) reduces the risk of sulfide stress cracking in environments containing H₂S.

6. Surface Coatings f0r B7M Stud bolts

To enhance performance and corrosion resistance, B7M stud bolts are often coated with:

- PTFE (Teflon) Coating:

- Provides excellent corrosion resistance and lubrication.

- Hot-Dip Galvanizing (HDG):

- Protects against atmospheric corrosion.

- Zinc Plating:

- Cost-effective corrosion protection.

- Cadmium Coating:

- For high-corrosion environments (though less common due to environmental concerns).

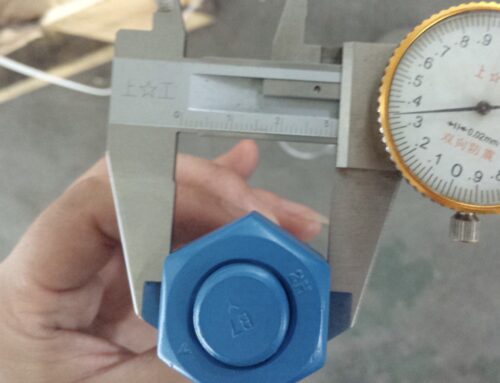

7. Marking and Identification

- Stud bolts are marked with:

- “B7M” to distinguish them from standard B7 bolts.

- Manufacturer’s logo and size.

- Heat number for traceability.

ASTM A193 B7M SA193 B7M Stud bolts with 2HM Hex Nuts order information.

SB2N,A193B7M,8UN,170mm,1.1/8in

Material Text:

Stud bolts with nuts

Mat spec, stud bolt(s) ASTM A193 GRADE B7M

Mat spec, nut(s) ASTM A194 GRADE 2HM

Coating Zn-Ni ELECTROPL + PTFE TOPCOAT

Design spec, stud bolt BS 4882

Design spec, nut ASME B18.2.2

BS 4882

Thread class symbol, stud bolt ASME B1.1 CLASS 2A

Thread class symbol, nut ASME B1.1 CLASS 2B

Type of thread ASME B1.1 SERIE 8UN

Type, nut UN HEAVY HEXAGONAL

Number, nuts per stud bolt 2

Mandatory requirements MESC SPE 81/007 2016

Inspection, certif EN 10204 -3.1

ISO 10474 -3.1

Caps code STB1 B7MC

Length 170 mm

6.75 in

Size 1.1/8 in

MESC code 8138173881