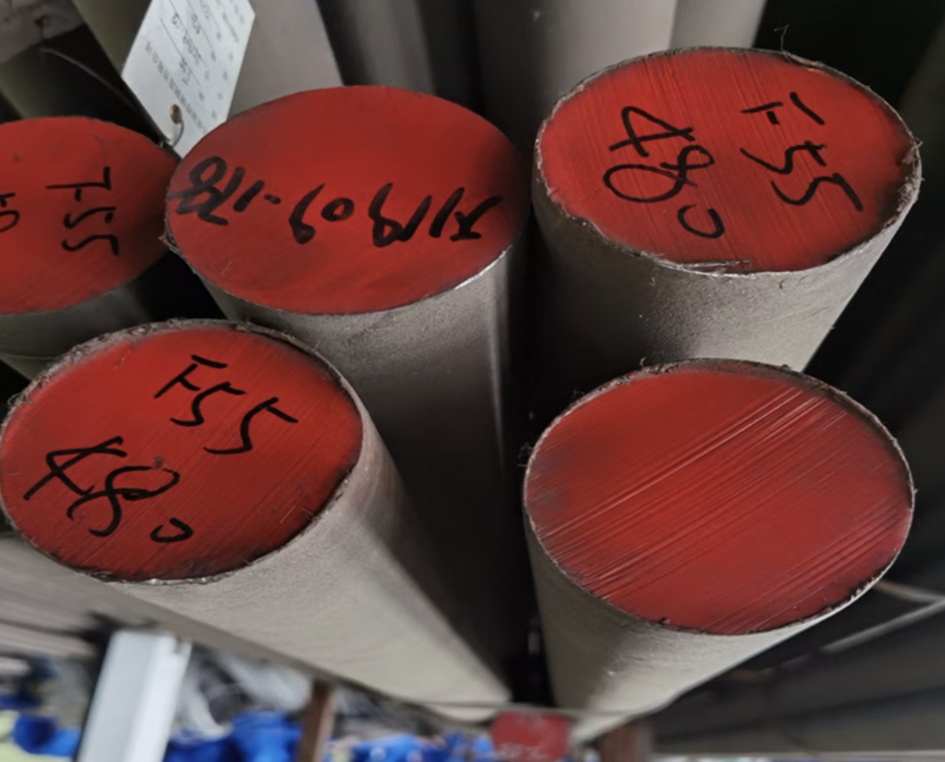

ASTM A182 F55 specification for Flanges,forged fittings

ASTM A182 F55 is a super duplex stainless steel (UNS S32760) used for forged fittings, flanges, valves, and other high-performance applications requiring superior corrosion resistance and strength.

UNS S32760 is a highly alloyed super duplex stainless steel with high PREN for use in aggressive environments.

| S32760 | |

| ASTM Specification or Grade |

F 55 |

| Corresponding Standard | ASTM A182/A182M-2018 Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service |

| Classification | Duplex Stainless Steel |

| Properties | Corrosion Resistance |

Chemical Element Composition Content (%) of ASTM A182 F55

| Component | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | N | W | More |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Minimum Value | – | – | – | – | – | 24 | 6 | 0.5 | 3 | 0.2 | 0.5 | Cr+3.3×Mo+16×N≥40 |

| Maximum Value | 0.03 | 1 | 1 | 0.03 | 0.01 | 26 | 8 | 1 | 4 | 0.3 | 1 |

Mechanical Properties of UNS S32760

| thickness t mm |

Heat Treatment or Condition | Tensile Strength σb Mpa |

Yield Point σs Mpa |

Elongation or Extension Rate δ % |

|---|---|---|---|---|

| All specifications | solution treat and quench | 750~895 | ≥550 | ≥25 |

ASTM A182 F55 Equivalent grade

| China | Japan | United States | International Organization for Standardization | Germany | European Standard | |||

| GB | ISC | JIS | UNS | ISO | DIN EN/DIN | W-Nr. | EN | Numerical Grade |

| 022Cr25Ni7Mo4WCuN 00Cr23Ni7Mo3.5WCuN* |

S27603 | SUS329J2L | S32760 | X2CrNiMoCuWN 25-7-4 | X2CrNiMoCuWN 25-7-4 | 1.4501 | X2CrNiMoCuWN 25-7-4 | 1.4501 |

Product Scope of ASTM A182 F55:

-

-

Flanges:

-

Weld Neck (WN), Slip-On (SO), Blind (BL), Threaded (TH), Socket Weld (SW), Lap Joint (LJ) flanges.

-

Available in pressure classes ranging from 150# to 2500# or higher, depending on size and application.

-

Used in high-pressure, high-temperature, and corrosive environments.

-

-

Forged Fittings ASME B16.11

-

Elbows, Tees, Caps, and other piping components.

-

Typically available in socket-welded, and threaded configurations.

-

Often used in chemical, marine, and offshore applications where resistance to stress corrosion cracking (SCC) and pitting corrosion is critical.

-

-

FAQ for ASTM A182 F55 (UNS S32760) Super Duplex Stainless Steel

1. What is ASTM A182 F55?

ASTM A182 F55 is a super duplex stainless steel (UNS S32760) used for forged flanges, fittings, valves, and pressure-containing components. It offers high strength, excellent corrosion resistance, and good weldability, making it ideal for harsh environments like offshore, marine, and chemical industries.

2.What is the difference between ASTM A182 F55 and F53?

-

Both are super duplex stainless steels, but F55 (UNS S32760) has higher copper and tungsten content, improving corrosion resistance in harsh environments.

-

F53 (UNS S32750) is slightly lower in corrosion resistance but still highly durable.

3. What are the main applications of ASTM A182 F55?

-

Offshore and subsea equipment

-

Oil and gas pipelines and flanges

-

Marine and shipbuilding industry

-

Chemical and petrochemical processing plants

-

Power generation and desalination plants

-

Pulp and paper industry

4. PREN Calculation of ASTM A182 F55

-

F55 (UNS S32760) has a higher PREN than standard duplex (2205) and even superaustenitic grades like 904L, making it highly suitable for marine, offshore, and aggressive chemical environments.

-

The Pitting Resistance Equivalent Number (PREN) for ASTM A182 F55 (UNS S32760) is calculated using the formula:

PREN=%Cr+3.3×%Mo+16×%NPREN = \%Cr + 3.3 \times \%Mo + 16 \times \%N