ASTM A193 B7 stud bolt with two ASTM A194 2H nutsC

China Manufactuer of ANSI/ASME b18.2.1 Fully Threaded Stud Bolts with ASME B18.2.2 Hex Nuts

ASME B18.2.1 is the American Society of Mechanical Engineers standard that defines the dimensional and material requirements for bolts, stud bolts, and other fasteners. A stud bolt is a threaded rod with threads at both ends (or full length)

ASME B18.2.1 Stud Bolts Threading:

The standard specifies the threading details such as:

Unified Inch Screw Threads per ASME B1.1.

Common thread classes: 2A for external threads (stud bolts).

Material:

- Materials must meet the mechanical property requirements specified by ASME. Common materials include:

- Carbon Steel

- Stainless Steel (e.g., SS316 for corrosion resistance)

- Alloy Steels

- Special high-temperature or corrosion-resistant alloys.

Nuts and Washers:

- Stud bolts are typically used with heavy hex nuts (specified in ASME B18.2.2) and sometimes washers, depending on the application.

Type: Stud Bolts and Nuts.

Material: ASTM A193 B7, ASTM A194 2H.

Standard: ASME B18.2.1, ASME B18.2.2.

I. Strength Grades

| DIN 931/933 | Grade 4.6, 4.8, 5.6, 5.8, 8.8, 10.9, 12.9 |

| DIN 931/933 | SUS 304, 316 |

| ASTM A307 | Grade A & B |

| ASTM A320, A320M | Grade L7, L7M, B8, B8M |

| ASTM A325, A325M | Grade 8.8 |

| ASTM A490, A490M | Grade 10.9 |

| ASTM A193/A193M | Grade B7, B7M, B8, B8M, B16 |

Surface Treatments

- Plating

- Zinc (White / Yellow / Black)

- Cadmium (White / Yellow / Black)

- Zinc Nickel

- Galvanising

- Hot-Dipped Galvanise

- Mechanical Galvanise

- Fluorocarbon Coating

Xylan® / PTFE Coating Systems:- Xylar 2

- 1070

- 1424

- Customised Coating Systems

- Zinc + Fluorocarbon / PTFE

- Cadmium + Fluorocarbon /PTFE

- Zinc Nickel + Fluorocarbon /PTFE

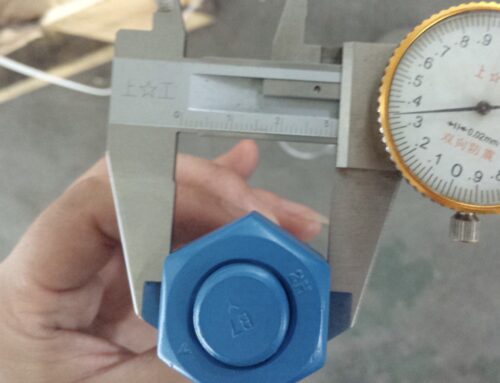

- Zinc Plating + Xylan 1424 Blue coated stud bolt

- Xylar 2 + Xylan 1070 Blue coated stud bolt

STAINLESS STEEL

A193 B6 – Heat treated 410 stainless (410HT)

A193 B8 – Produced to grade AISI 304, carbide solution treated, standardly available in class 1

A193 B8M – Produced to grade AISI 316, carbide solution treated, standardly available in class 1

A193 B8C- Grade 347 stainless material

A193 B8T – Grade 321 stainless material

A320 B8 – Produced to grade AISI 304, carbide solution treated, standardly available in class 1

A320 B8M – Produced to grade AISI 316, carbide solution treated, standardly available in class 1

| B7 | Alloy steel, AISI 4140/4142 quenched and tempered |

|---|---|

| B8 | Class 1 Stainless steel, AISI 304, carbide solution treated. |

| B8M | Class 1 Stainless steel, AISI 316, carbide solution treated. |

| B8 | Class 2 Stainless steel, AISI 304, carbide solution treated, strain hardened |

| B8M | Class 2 Stainless steel, AISI 316, carbide solution treated, strain hardened |

| B16 | A heat-treated chromium-molybdenum-vanadium steel for high-pressure, high-temperature service. |

Mechanical Properties

Bolt -Grade Identification Markings

| Grade | Size | Tensile ksi, min | Yield, ksi, min | Elong, %, min | RA % min |

|---|---|---|---|---|---|

| B7 | Up to 2-1/2 | 125 | 105 | 16 | 50 |

| 2-5/8 – 4 | 115 | 95 | 16 | 50 | |

| 4-1/8 – 7 | 100 | 75 | 18 | 50 | |

| B8 Class 1 | All | 75 | 30 | 30 | 50 |

| B8M Class 1 | All | 75 | 30 | 30 | 50 |

| B8 Class 2 | Up to 3/4 | 125 | 100 | 12 | 35 |

| 7/8 – 1 | 115 | 80 | 15 | 35 | |

| 1-1/8 – 1-1/4 | 105 | 65 | 20 | 35 | |

| 1-3/8 – 1-1/2 | 100 | 50 | 28 | 45 | |

| B8M Class 2 | Up to 3/4 | 110 | 95 | 15 | 45 |

| 7/8 – 1 | 100 | 80 | 20 | 45 | |

| 1-1/8 – 1-1/4 | 95 | 65 | 25 | 45 | |

| 1-3/8 – 1-1/2 | 90 | 50 | 30 | 45 | |

| B16 | Up to 2-1/2 | 125 | 105 | 18 | 50 |

| 2-5/8 – 4 | 110 | 95 | 17 | 45 | |

| 4-1/8 – 7 | 100 | 85 | 16 | 45 |

Material Chemical Composition

| Element | B7 (AISI 4140) | B8 (AISI 304) | B8M (AISI 316) | B16 (AISI 4140) |

|---|---|---|---|---|

| Carbon | 0.37 – 0.49% | 0.08% max | 0.08% max | 0.37 – 0.49% |

| Manganese | 0.65 – 1.10% | 2.00% max | 2.00% max | 0.65 – 1.10% |

| Phosphorus, max | 0.035% | 0.045% | 0.045% | 0.035% |

| Sulfur, max | 0.040% | 0.030% | 0.030% | 0.040% |

| Silicon | 0.15 – 0.35% | 1.00% max | 1.00% max | 0.15 – 0.35% |

| Chromium | 0.75 – 1.20% | 18.0 – 20.0% | 16.0 – 18.0% | 0.75 – 1.20% |

| Nickel | 8.0 – 11.0% | 10.0 – 14.0% | ||

| Molybdenum | 0.15 – 0.25% | 2.00 – 3.00% | 0.15 – 0.25% |

Recommended Nuts,Bolts & Washer

| Bolt Grade | Nuts | Washers |

|---|---|---|

| B7 | A194 Grade 2H | F436 |

| B8 Class 1 | A194 Grade 8 | SS304 |

| B8M Class 1 | A194 Grade 8M | SS316 |

| B8 Class 2 | A194 Grade 8 | SS304 |

| B8M Class 2 | A194 Grade 8M | SS316 |