DIN 976 – Metric thread stud bolts.

Current norm: DIN 976-1. Equivalent norms: UNI 6610;.

DIN 976 is a standard for metric thread stud bolts (threaded rods) that specifies their dimensions, material properties, and mechanical requirements. These threaded rods are used in various applications, including construction, machinery, and structural connections.

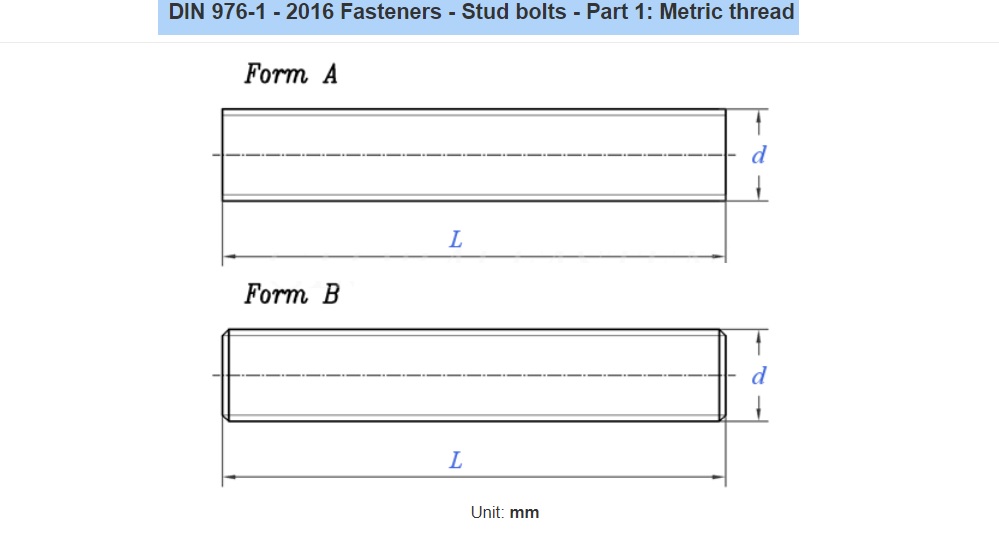

Specificaton of stud-bolt-din 976-1

-

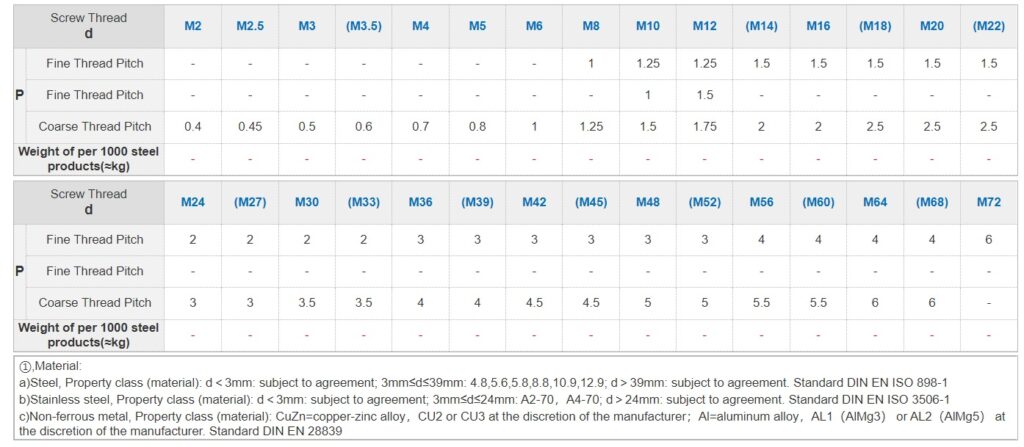

Threading:

- Metric Threads: Fully threaded or partially threaded as per ISO metric thread standards.

- Thread pitch, diameter, and tolerance are defined by ISO 965-1 and ISO 965-2.

- Available in coarse or fine thread series.

-

Dimensions:

- Diameter Range: From M3 to M52 (common range, larger sizes available upon request).

- Lengths: Typically available in lengths from 1 meter to 3 meters, though custom lengths can be supplied.

-

Materials:

- Carbon Steel Grades:4.6, 5.6, 8.8, 10.9, and 12.9.

- Stainless Steel Grades:

- A2 (AISI 304) for general corrosion resistance.

- A4 (AISI 316) for high corrosion resistance, including marine environments.

- Other Materials: Brass, aluminum, or titanium for specialized applications.

-

Surface Finishes:

- Zinc-plated or electro-galvanized.

- Hot-dip galvanized (HDG) for corrosion protection in outdoor environments.

- Black oxide or PTFE-coated for specific requirements.

-

Mechanical Properties:

- Property Classes (Steel):

- Class 4.6, 5.6, 8.8, 10.9, and 12.9.

- Indicates tensile strength, yield strength, and ductility.

- Stainless Steel Grades:

- A2-50, A2-70, A4-70, and A4-80, indicating tensile strength and corrosion resistance.

- Property Classes (Steel):

-

Standards Compliance:

- Threads conform to ISO 261 and ISO 965 standards.

- Materials and mechanical properties align with DIN EN ISO 898-1 (for carbon and alloy steel fasteners).

-

Marking:

- Identification: Typically marked with property class, manufacturer’s symbol, and batch number for traceability.

- Stainless steel is often marked with “A2” or “A4” along with the property class (e.g., A4-70).

Applications of DIN 976 Threaded Rods

- Construction: Structural connections, anchoring, and framing.

- Machinery: Fastening components and equipment.

- Piping Systems: Supports and securing pipeline components.

- Automotive: Assembled parts requiring precise and secure connections.

DIN 976 (preplaces DIN 975) Technical Specifications

This standard covers stud bolts with threads produced to tolerance 6g which is customary for bolt/nut assemblies of thread engagement group N as specified

Metric DIN 976 Fully Threaded Stud Bolts are headless bolts threaded all the way from one end to the other (full / all thread). They are designed for a nut to be applied on both ends and are often used for electrical, construction and plumbing for hanging purposes. Aspen Fasteners offers one of the most complete ranges of metric studs and other inch and metric industrial fasteners for immediate delivery from stock. The following sizes of metric DIN 976 Fully Threaded Stud Bolts are available for immediate shipping from stock: Diameters ranging from M2 to M52 and lengths to 1000mm in A2 and marine grade A4 stainless steel.

DIN (Deutsches Institut für Normung – German Institute for Standardization) standards are issued for a variety of

components including industrial fasteners as Metric DIN 939 double end studs. The DIN standards remain common in

Germany, Europe and globally even though the transition to ISO standards is taking place. DIN standards continue to be

used for parts which do not have ISO equivalents or for which there is no need for standardization.

Technical delivery conditions

| Characteristic | Standard | |

|---|---|---|

| Material | ||

| General Requirements | ||

| Thread | Tolerance | 6g |

| Standard | DIN ISO 965-2 | |

| Mechanical Properties | Property Class (material) | For sizes M3 up to M39: 4.8, 5.6, 5.8, 8.8, 10.9 or 12.9. |

| For sizes above M39: subject to agreement. | ||

| Standard | DIN EN ISO 898-1 (test programme B). | |

| Limit deviations and geometrical tolerances3 | Product Grade | A |

| Standard | DIN EN ISO 4759 Part 1 | |

| Surface finish | As processed. | |

| DIN 267 Part 2 applies with regard to surface roughness. | ||

| DIN EN ISO 4042 applies with regard to electroplating. | ||

| DIN EN ISO 10683 applies with regard to zinc flake coatings. | ||

| Surface discontinuities | DIN EN 26157-3 applies with regard to limits for surface discontinuities for property classes 5.6, 8.8, 10.9 and 12.9 | |

| Acceptability | DIN 267 Part 5 shall apply with regard to acceptance inspection. | |

| a : For stud bolts with nominal lengths of 1000mm or more, the tolerance on length shall be js17 (product grade B as in DIN EN ISO 4759-1). |