China Manuafacturer of Hot Dip Galvanized ASTM A193 B7M Stud Bolt Full thread HDG ASTM F2329

What is A193 B7M Stud Bolt?

ASTM A193 B7M is an alloy steel grade typically for Stud bolt or thread rod used in the oil and gas industries where the bolting could be exposed to the environments containing H2S.Our stud bolt A193 B7M is NACE MR 0175 complied.

A193 B7M ,the same as B7 ,which is made from AISI 4140/4142 low Carbon Alloy Steel Grades followed by quencing & tempering.

ASTM A193 Grade B7M bolts and studs are identical in chemistry to Grade B7 (quenched and tempered medium carbon alloy steel), but have lower strength requirements and require 100% hardness testing of all fasteners manufactured in the lot. Grade B7M bolts resist chloride, sulfide, and hydrogen stress corrosion cracking (SCC) and are frequently used in sour gas service.

ASTM A193 Grade B7M Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr |

| ASTM A193 Grade B7M | MIN | 0.37 | 0.65 | 0.15 | 0.75 | ||

| MAX | 0.49 | 1.10 | 0.035 | 0.040 | 0.35 | 1.20 |

Mechanical Properties of B7M

- Tensile Strength: 100 – 115 ksi

- Yield Strength: ≥ 65 ksi

- Elongation: ≥ 20%

- Hardness: ≤ 235 HB

ASTM A193 Grade B7M heat Treatment

B7M shall be heat treated by quenching in a liquid medium and tempering. For B7M fasteners, the final heat treatment, which may be the tempering operation if conducted at 1150 °F [620 °C] minimum, shall be done after all machining and forming operations, including thread rolling and any type of cutting.

Applications of A193 B7M Stud Bolt

The A193 B7M Stud Bolt is widely used in industries such as:

- Oil & Gas: Suitable for sour service conditions and H2S-rich environments.

- Petrochemical Plants: Ideal for flange connections, pressure vessels, and heat exchangers.

- Chemical Processing: Resists corrosion from aggressive chemicals.

- Power Plants: Performs well in high-pressure and high-temperature systems.

Difference between A193 B7M and B7

There are some significant differences in both the mechanical properties and testing requirements of A193 B7M and A193 B7.

| Property | B7 | B7M |

|---|---|---|

| Tensile Strength | Minimum 125 ksi (860 MPa) | 100–115 ksi (690–790 MPa) |

| Yield Strength | Minimum 105 ksi (720 MPa) | 65 ksi (450 MPa) minimum |

| Hardness | Maximum 35 HRC (~320 HBW) | Maximum 235 HBW |

B7 has higher tensile and yield strength, making it suitable for standard high-pressure and high-temperature applications.

B7M has reduced mechanical properties to mitigate the risk of hydrogen embrittlement in sour service environments.

About Hot Dip Galvanized (HDG)

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °C (842 °F)

Standard Specification for Zinc Coating, Hot-Dip, Requirements for Application to Carbon and Alloy Steel Bolts, Screws, Washers, Nuts, and Special Threaded Fasteners

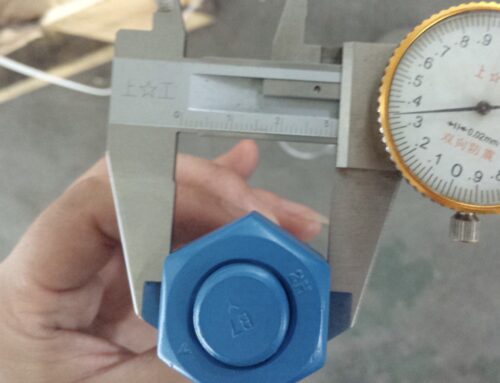

Zinc Coating thickness requirement for ASTM F2329 ASTM A193 Grade B7M Stud bolt

| Minimum Thickness on Surface | |||

|---|---|---|---|

| Dimension A, B | Average Thickness of All Specimens Tested (Production Lot) C, B | Average Thickness of All Specimens Tested (Batch Lot) D, B | Average Thickness of Individual Specimen B |

| Fasteners and nuts over 3⁄8 in. [M10] in diameter | 0.0020 in. [50 μm] | 0.0017 in. [43 μm] | 0.0017 in. [43 μm] |

| Washers 3⁄16 in. [4.7 mm] and over in thickness | |||

| Fasteners and nuts 3⁄8 in. [M10] and under in diameter | 0.0017 in. [43 μm] | 0.0015 in. [38 μm] | 0.0015 in. [38 μm] |

| Washers under 3⁄16 in. [4.7 mm] in thickness | |||

ASTM A193 Grade B7M Stud bolt order specfication

Name: Threaded Bolts A193 B7M

Material: A193 B7M

Length: 150mm

Application: Bolts are Used in the Assembly of Solar Panels and Supporting Structures

Treatment: HDG

Size: 2-1/2 Inch

Thread: 8 UNC

Other coating options for ASTM A193 Grade B7M Stud bolt

- PTFE (Teflon): For improved chemical resistance.

- Zinc Plating: Provides rust prevention in non-corrosive environments.

- Phosphate Coating: Enhances adhesion and corrosion resistance.