All informations about xylan coating you need to know

What is xylan Coating?

Xylan is a known as a registered brand name for a type of fluoropolymer coating. Previous held by Whitford,Now PPG company. Xylan Coating now has a long-standing reputation as the reference standard for industrial coatings.

Xylan coating is an extreme performance coating, explicitly designed to improve the performance and extend the life of various industrial and consumer products.

Xylan coating is a high-performance, fluoropolymer-based coating designed to enhance the durability and functionality of fasteners, components, and industrial parts. It combines corrosion resistance, reduced friction, and high-temperature performance, making it ideal for demanding applications.

XYLAN® coatings help improve performance and extend the life of components. This trusted technology protects from corrosion, chemicals and abrasion, as well as provides low-friction properties to improve release compared to uncoated parts. Xylan is a proven solution for use in many markets including Energy generation and Oil and Gas.

Xylan® coatings are a family of

fluoropolymer and fluoropolymer hybrid coatings.

Xylan® coatings provide dry lubrication, controlled friction, wear resistance,

Benefits of Xylan coating

- Highly ductile, meaning Xylan coatings can bend freely and repeatedly without breaking

- Adheres to various substrates, including metals, plastics, ceramics, glass and wood

- Highly heat resistant, with operating temperatures from -227°C to +288°C

- Resistant to corrosion and aggressive chemicals in various environments

- Weather resistant to rain water, salt water and strong UV sunlight

- Non-adhesive, with minimal coefficient of friction (only 0.02)

- Wear resistant, even under extreme pressure

Applications of Xylan Coating

- Fasteners and Bolts:

- Stud bolts, Hex nut,nuts, for marine, oil and gas, and chemical industries.

- Automotive Components:

- Reduces friction in engine parts, improving efficiency and durability.

- Aerospace Equipment:

- Lightweight and durable coating for high-stress applications.

- Industrial Machinery:

- Protects moving parts in harsh operational environments.

- Pipeline and Valves:

- Prevents corrosion and chemical degradation in fluid systems.

Types of Whitford Xylan Coating

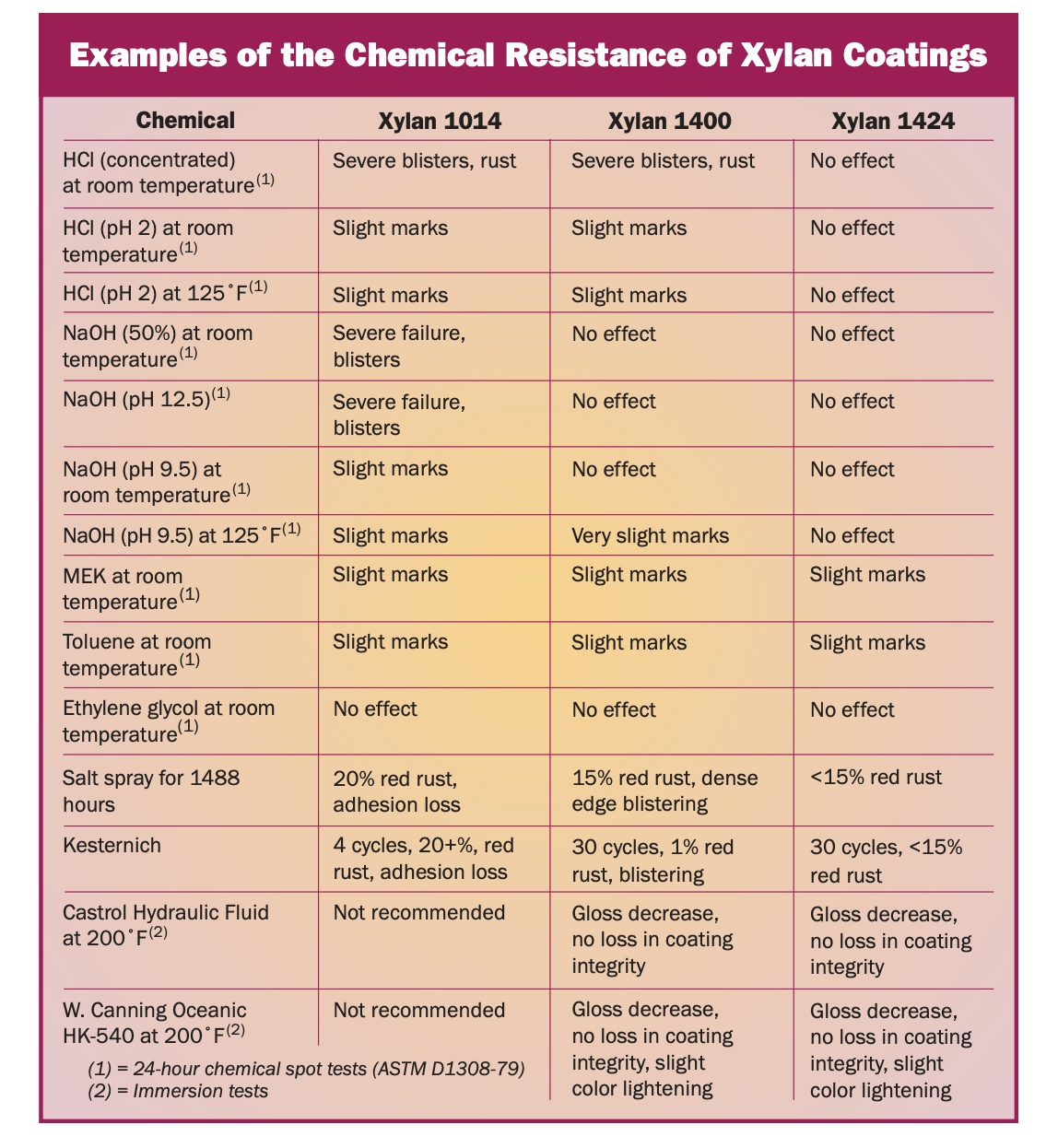

There are several varieties of Xylan coatings. it is important to know the character of each type for your coating selection.

- Xylan 1070 coating – Protect your bolts against corrosion and adhesive environments to extend durability and save on maintenance costs

- Xylan 1424 coating – Typical applications are large fasteners and automotive parts

- Xylan 1014 Coating Xylan® 1014 series coating is a resin-based material which produces finishes that are harder, more abrasion resistant, glossier, and less porous.

Xylan 1070 -Coating Technical Data

| Property |

Standard |

Results |

| Corrosion resistance |

ASTM B117

ASTM D610 |

5000 hours / rust grade 10 |

| Coefficient of friction |

ASTM G99 |

0.05 – 0.12 |

| Working temperature range |

– |

-195°C – +260°C / -319°F – +500°F |

| Dry-film thickness |

ASTM D1186 |

15 – 25 μm / 0.6 – 1.0 mils (1 or 2 coats is typical, which reflects the TDS) |

| Film hardness |

ASTM D3363 |

2H – 4H per coat (1 or 2 coats is typical, which reflects the TDS) |

Xylan FAQ

1.What is Xylan?

Xylan is a family of fluoropolymer coatings designed by Whitford to provide corrosion protection, lubrication, wear resistance and non-stick properties in a variety industries and applications.

2,Difference tween Xylan 1424 and Xylan 1070?

Xylan 1424 – Xylan 1424 is a water-resistant, low-friction coating with relatively high resistance to abrasion, chemical degradation and corrosion. These attributes make Xylan 1424 especially ideal for caustic environments. This type of coating is also VOC-compliant for environmentally sensitive and sustainable applications.

Xylan 1070 – Like Xylan 1424, Xylan 1070 is water-resistant, has a low coefficient of friction, and also possesses formidable corrosion and heat resistance. This PTFE coating is ideal for leak prevention in tanks, vessels and valves operating in relatively aggressive environments. (For more information on protecting process vessels, read Introduction to Managing Internal Corrosion in Process Vessels.

3 How do you apply Xylan Coating?

Xylan coatings require meticulous pre-treatment, application and curing processes, therefore must be applied by an experienced applicator, preferably with QAC (Quality Approved Coater) certification.

Our xylan coating procedure.

1: Applying a base-coat such as Phosphate, Zinc, Zinc-Nickel, Hot Dip Galvanized or Xylar 1. The base coat has an average thickness of 10-15µ (except for HDG).

2, Glass-shot blasting to roughen the surface of the fasteners to be coated.

3,Having fasteners coated with PTFE Xylan 1070 or Xylan 1424 in the required color. See the table below for the top coat most suited to for your situation.

4: Heat treatment of the coated fasteners is performed.

4.Is Xylan the same as PTFE Coating?

Generally,yes… Xylan is one kind of PTFE (Polytetrafluoroethylene) coatings.

5.Do you supply Xylan coated fasteners?

Yes. Amongst the Xylan range are a series of fastener-class coating systems designed to improve the performance and longevity of all types, sizes and grades of fasteners through its excellent corrosion resistant and low-friction properties. Xylan can be applied via dip-spin and spray methods, meaning it is suitable for small screws right through to large stud bolts.

6.What is Xylan Blue?

Xylan actually comes in a wide range of colours but is often referred to as “Xylan Blue” or “PTFE Blue” in reference to coating B7 Stud Bolts and Nuts for the Petrochemical industry. Generally, the most popluar PTFE Coating material for the stud bolt and nuts are Xylan 1424 and Xylan 1070

7.What are the addtional coating type you can supply?

Zinc + Fluorocarbon / PTFE

Cadmium + Fluorocarbon /PTFE

Zinc Nickel + Fluorocarbon /PTFE

Zinc Plating + Xylan 1424 Blue

Xylar 2 + Xylan 1070 Blue

Xylar 2 + xylar 101 coated stud bolt

8.Xylan 1424 coated stud bolts order information.?

Stud Bolt 1″x180mm + 2 Heavy Hex Nuts ASME B18.2.1/B18.2.2/B1.1 Cl.2A/2B ASTM A 193 Gr.B7 – A 194 Gr.2H Fluorocarbon Coated blue color