Flange Insulation Kit ASME B16.5,Flange Isolating Gasket Kits

China manufacturer and exporter of Flange Insulation Kit ASME B16.5,Flange Isolating Gasket Kits

Flange Isolation Gasket Kits are manufactured according to ANSI B16.5 specifications up to 24″.

Gasket sets for flange insulation are designed to ensure the integrity and reliability of the pipeline and piping system through safety and corrosion protection. By eliminating metal-to-metal contact, static flow is stopped to prevent corrosion and aid in the cathodic protection of the piping system.

Flange insulation gasket kits provide both effective sealing and reliable electrical insulation of flanges. Made of high-quality materials with high dielectric constant and low water absorption. Flange insulation gaskets kits are available in different configurations to meet any possible need. Flange insulation gasket kits come in all DIN, ASME and API classes.

Flange Insulation kits can be used in the petrochemical, oil refinery, offshore seawater environments, where the transfer of volatile fluids through the pipeline can create explosive conditions which could be ignited by stray electrical currents.

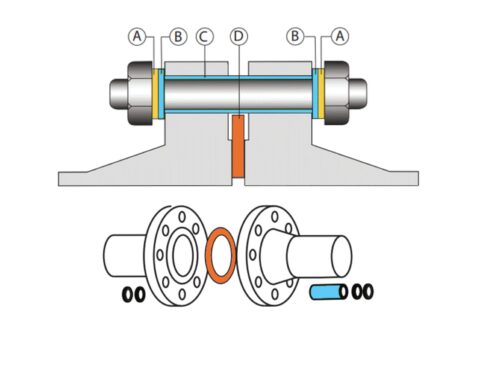

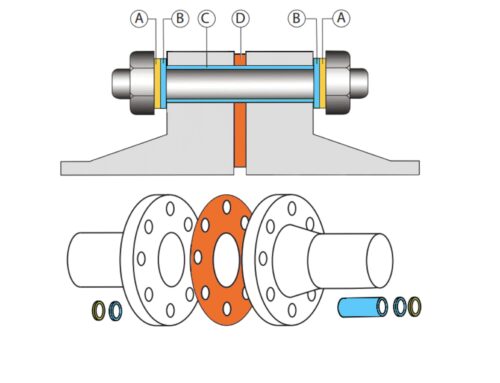

Each flange insulation set comprises one central flat or oval section gasket, plus one insulation sleeve, two insulating and two plated steel washers per bolt. The sets are individually packed and clearly labelled with the flange rating, size, type and material combination.

Components of a Flange Isolation Kit

A typical flange isolation kit includes:

- Isolation Gasket:

- Types: Full-face, ring-type, or specific designs like the API RTJ.

- Materials: Phenolic, PTFE (Teflon), G10/G11 (fiberglass-reinforced epoxy), or high-temperature options like mica or spiral-wound designs.

- Isolation Sleeves:

- Insulate the bolts from the flange.

- Made of non-conductive materials like Mylar, G10, or Nomex.

- Isolation Washers:

- Two per bolt (one insulating, one metallic for load distribution).

- Materials: Nylon, phenolic, or G10.

- Metallic Washers:

Types of Flange Isolation Kits

Type D:

Gaskets are specifically designed to fit into the ring groove of ring-type-joint flanges. They are manufactured of a medium weave, fabric-reinforced phenolic material and are sized to ANSI specifications available in basic oval as well as octagonal shape. BX gaskets with pressure rating to 15,000 PSI.

Type E:

a full-faced gasket with the same outside diameter as the flange and precision cut bolt holes. This design facilitates proper alignment of the gasket during installation and foreign material prevented from shorting the flange insulation. The type E gaskets are available in plain face or Neoprene face phenolic, as well as a variety of high temperature materials.

Type F:

The gasket is made to fit the raised face portion of the flange only. As there are no bolts holes in the F style gasket, the inside diameter of the bolt hole circle is slightly smaller than the outside diameter of the gasket.

Metallic Core

The metallic core of gasket is made of stainless steel 316L.

Other metals, including Duplex and Inconel are available upon request.

Isolating Material

1) G-10 Glass-Reinforced Epoxy (GRE) laminate:

Compressive Strength: 65,000 PSI

Dielectric Strength: 750-800 VPM

Max. Continuous Operating Temp: 300 degrees F (150 degrees C)

Water Absorption: .05%

Flexural Strength: 65,000 PSI

Tensile Strength: 50,000 PSI

2) G-11 Glass-Reinforced Epoxy (GRE) High Temp. laminate material:

Compressive Strength: 50,000 PSI

Dielectric Strength: 500 VPM

Max. Continuous Operating Temp: 398 degrees F (200 degrees C)

Water Absorption: .085%

Flexural Strength: 57,700 PSI

Tensile Strength: 41,000 PSI

Seal Material

PTFE (Spring-Energized)

Viton

Buna-Nitrile

Isolating Sleeve

GRE

Mylar

NOMEX

Isolating Washers

GRE – G10/G11

HCS Washers

Steel Washer

ZPS

XPS

Stainless Steel Washers

Flange Isolation Gasket Kits are critical components designed to prevent galvanic corrosion, enhance sealing, and electrically isolate flanges in pipeline systems.