Stud Bolts & Hex Nuts Material for Flanges

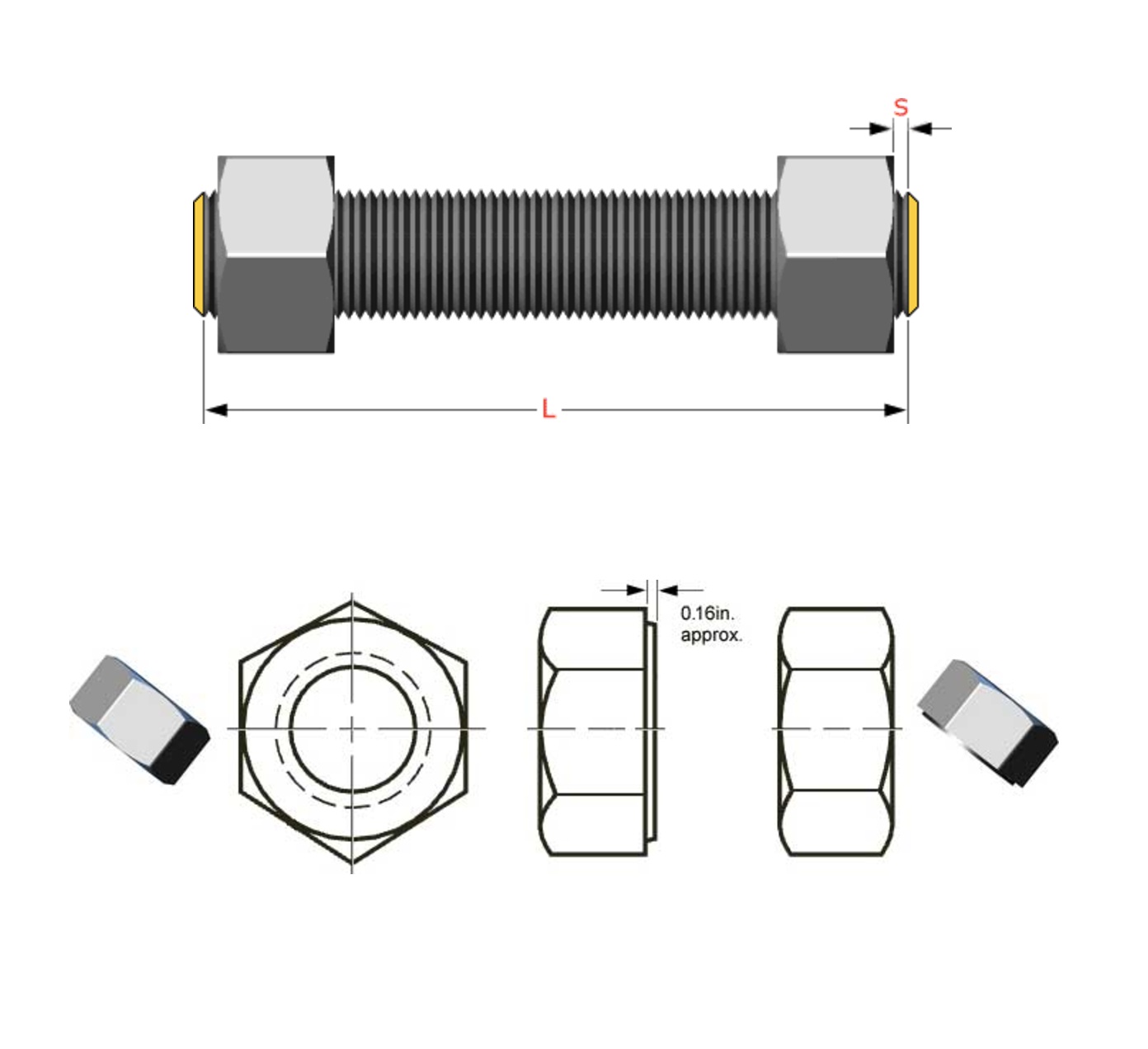

The Stud Bolt is a threaded rod assembled with 2 heavy hexagon nuts,normally 1 hex nut on each end.

Stud Bolts general

The quantity of bolts for a flange connection will be given by the number of bolt holes in a flange, diameter and length of bolts is dependent of flange type and Pressure Class of flange.

Stud Bolt length are defined in ASME B16.5 standard. The length in inches is equal to the effective thread length measured parallel to the axis, from the first to the first thread without the chamfers (points).

There are different grades of stud bolt and hex nuts can be used for different flange material and conditions.

Various Type Coatings are possible.

-

- Plating

- Zinc (White / Yellow / Black)

- Cadmium (White / Yellow / Black)

- Zinc Nickel

-

- Galvanising

- Hot-Dipped Galvanise

- Mechanical Galvanise

-

- Fluorocarbon Coating

Xylan® / Dupont Coating Systems:

- Xylar 2

- Xylan 1070

- Xylan 1424

- Customised Coating Systems

- Zinc + Fluorocarbon / PTFE coated stud bolt

- Cadmium + Fluorocarbon /PTFE coated stud bolt

- Zinc Nickel + Fluorocarbon /PTFE coated stud bolt

- Zinc Plating + Xylan 1424 Blue PTFE coated stud bolt

- Xylar 2 + Xylan 1070 coated stud bolt

Thread specification for Stud bolt

| Nomonal Size or Diameter of stud-bolt [D] |

D=1″[25mm] & Smaller |

D=1 ⅛[28mm] & Larger |

| Thread |

INCH Series |

Unified Coarse Thread Series Class 2A and 2B ANSI B1.1 |

Unified 8-Thread[3-pitch] Series Class 2A and 2B ANSI B1.1 |

| METRIC series |

METRIC Coarse Thread Series Class 6G and 6H JIS B0209/ISO 261 |

METRIC 3-pitch Series Class 6G and 6H JIS B0209/ISO 261 |

| INCH Series |

METRIC Series |

Comform to Heavy Hex Nuts of ANSI B 18.2.2

Double chamfered of Washer faced |

Comform to Heavy Hex Nuts of ANSI 18.2.2

Double chamfered of Washer faced |

Mechanical Requirements for Stud bolts

| Specification Grade |

Diameter inch (mm) |

Tesile Strength Min |

Yiled Strength Min |

E.L % Min |

R.A % Min |

Haedness |

Tempering Temp”F (“c) Min |

| HB |

H.B |

H.C |

| A193 Gr B7 |

2½ and under |

125,000psi |

100,000psi |

16 |

50 |

|

|

|

1,100(593) |

| Over 2½ to 4 |

115,000psi |

95,000psi |

16 |

50 |

|

|

|

1,100(593) |

| A193 Gr B7M |

2½ and under |

105,000psi |

80,000psi |

18 |

50 |

200-235 |

93-99 |

|

1,150(620) |

| A193 Gr B16 |

2½ and under |

125,000psi |

105,000psi |

18 |

50 |

253-319 |

|

25-34 |

1,200(650) |

| Over 2½ to 4 |

110,000psi |

95,000psi |

17 |

45 |

353-319 |

|

25-34 |

1,200(650) |

| A193GrB8.B8M |

All diameters |

75,000psi |

30,000psi |

30 |

50 |

Max 223 |

Max 96 |

|

|

| A193 Gr B6 |

Up to 4 |

110,000psi |

85,000psi |

15 |

50 |

|

|

|

1,100(593) |

| A320 Gr L7 |

2½ and under |

125,000psi |

105,000psi |

16 |

50 |

|

|

|

|

| A320 Gr L7M |

2½ and under |

100,000psi |

80,000psi |

18 |

50 |

Max 235 |

Max 99 |

|

1,150(620) |

| A320GrB8.B8M |

All diameters |

75,000psi |

30,000psi |

35 |

50 |

Max 223 |

Max 96 |

|

|

| A325 |

½ to 1 |

120,000psi |

92,000psi |

|

|

248-331 |

|

24-35 |

800(427) |

| 1⅛ to 1½ |

105,000psi |

81,000psi |

14 |

35 |

223-293 |

|

19-31 |

800(427) |

| A354 Gr BC |

¼ to 2½ |

125,000psi |

109,000psi |

16 |

50 |

255-331 |

|

26-36 |

800(427) |

| Over 1 to 1½ |

115,000psi |

99,000psi |

16 |

45 |

235-311 |

|

22-33 |

800(427) |

| A354 Gr BD |

¼ to 2½ |

150,000psi |

130,000psi |

14 |

40 |

311-363 |

|

33-39 |

800(427) |

| Over 1 to 1½ |

140,000psi |

115,000psi |

14 |

40 |

293-363 |

|

31-39 |

800(427) |

| A449 |

¼ to 1 |

120,000psi |

92,000psi |

14 |

35 |

255-321 |

|

25-34 |

800(427) |

| Over 1 to1½ |

105,000psi |

81,000psi |

14 |

35 |

223-285 |

|

19-30 |

800(427) |

| Over 1½ to 3 |

90,000psi |

58,000psi |

14 |

35 |

183-235 |

|

|

800(427) |

| A490 |

½ to 1½ |

150-170ksi |

130,000ksi |

14 |

40 |

311-352 |

|

33-38 |

800(427) |

| JIS SUS 310S |

|

53 kgf/㎟ |

21kgf/㎟ |

40 |

50 |

Max 187 |

Max 90 |

|

|

| JIS SCM 435 |

|

95kgf/㎟ |

80kgf/㎟ |

15 |

50 |

269-331 |

|

29-35 |

(530-630) |

| JIS SCM 440 |

|

100kgf/㎟ |

85kgf/㎟ |

12 |

45 |

285-352 |

|

29-39 |

(530-630) |

| JIS SNB 5 |

|

70kgf/㎟ |

56kgf/㎟ |

16 |

50 |

|

|

|

(595) |

| JIS SNB 7 |

Up to 63(mm) |

88kgf/㎟ |

74kgf/㎟ |

16 |

50 |

|

|

|

(595) |

| Over(63) to (100) |

82kgf/㎟ |

67kgf/㎟ |

16 |

50 |

|

|

|

(595) |

| JIS SNB 16 |

Up to 63(mm) |

88kgf/㎟ |

74kgf/㎟ |

18 |

50 |

|

|

|

(650) |

| Over (63) to (100) |

77kgf/㎟ |

67kgf/㎟ |

17 |

50 |

|

|

|

(650) |

| JIS S45C |

|

70kgf/㎟ |

50kgf/㎟ |

17 |

45 |

201-269 |

|

14.5-27 |

(550-650) |

| A194 Gr 2 |

|

|

|

|

|

159-352 |

Min 84 |

|

1,000(538) |

| A194 Gr 2H |

To 1½ |

|

|

|

|

248-352 |

|

24-38 |

850(455) |

| Over 1½ |

|

|

|

|

212-352 |

Min 95 |

Max 38 |

850(455) |

|

|

|

|

|

|

159-237 |

|

Max 22 |

1,150 |

|

|

|

|

|

|

228-271 |

|

20-28 |

1,100 |

|

|

|

|

|

|

159-237 |

|

Max 22 |

1,100 |

|

|

|

|

|

|

248-352 |

|

24-38 |

1,100 |

|

|

|

|

|

|

126-300 |

60-105 |

|

|

| A563 Gr A |

¼ to 4 |

|

|

|

|

116-302 |

Min 68 |

Max 32 |

|

| A563 Gr B |

¼ to 1½ |

|

|

|

|

121-302 |

Min 69 |

Max 32 |

|

| A563 Gr C |

¼ to 4 |

|

|

|

|

143-352 |

Min 78 |

Max 38 |

800(427) |

| A563 Gr D |

¼ to 4 |

|

|

|

|

159-352 |

Min 84 |

Max 38 |

800(427) |

| A563 Gr DH |

¼ to 4 |

|

|

|

|

248-352 |

|

24-38 |

800(427) |

Chemical Requirements for stud bolts

| SpecificationGrade |

C |

Si |

Mn |

PMax |

SMax |

Ni |

Cr |

Mo |

Vanadium |

| ASTM A193 Gr B7 |

0.37-0.49 |

0.15-0.35 |

0.65-1.10 |

0.035 |

0.04 |

|

0.75-1.20 |

0.15-0.25 |

|

| ASTM A193 Gr B7M |

0.37-0.49 |

0.15-0.35 |

0.65-1.10 |

0.035 |

0.04 |

0.75-1.20 |

0.15-0.25 |

|

| ASTM A193 Gr B16 |

0.36-0.47 |

0.15-0.35 |

0.45-0.70 |

0.035 |

0.04 |

0.80-1.15 |

0.50-0.65 |

0.25-0.35 |

| ASTM A193 Gr B8 |

Max 0.08 |

Max 1.00 |

Max 2.00 |

0.045 |

0.03 |

8.00-10.5 |

18.0-20.0 |

|

|

| ASTM A193 Gr B8M |

Max 0.08 |

Max 1.00 |

Max 2.00 |

0.045 |

0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

| ASTM A193 Gr B6 |

Max 0215 |

Max 1.00 |

Max 1.00 |

0.045 |

0.03 |

|

|

11.5-13.5 |

| ASTM A320 Gr L7 |

0.38-0.48 |

0.15-0.35 |

0.75-1.00 |

0.035 |

0.04 |

|

0.80-1.10 |

0.15-0.25 |

|

| ASTM A320 Gr L7M |

0.38-0.48 |

0.15-0.35 |

1.75-1.00 |

0.035 |

0.04 |

|

0.80-1.10 |

0.15-0.25 |

| ASTM A320 Gr B8 |

Max 0.08 |

Max 1.00 |

Max 2.00 |

0.045 |

0.03 |

8.00-10.5 |

18.0-20.0 |

|

| ASTM A320 Gr B8M |

Max 0.08 |

Max 1.00 |

Max 2.00 |

0.045 |

0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

| ASTM A325 TYPE 1 |

0.28-0.55 |

|

Min 0.60 |

0.040 |

0.05 |

|

Boron Min 0.0005 |

| ASTM A325 TYPE 2 |

0.15-0.34 |

Min 0.70 |

0.040 |

0.05 |

| ASTM A354 Gr BC |

0.30-0.53 |

|

0.035 |

0.04 |

| ASTM A354 Gr BD |

0.30-0.53 |

0.035 |

0.04 |

| ASTM A449 TYPE1 |

0.28-0.55 |

|

Min 0.60 |

0.040 |

0.05 |

|

Boron Min 0.0005 |

| ASTM A449 TYPE 2 |

0.15-0.38 |

Min 0.70 |

0.040 |

0.05 |

| ASTM A490 TYPE1 |

0.30-0.48 |

|

0.040 |

0.04 |

| JIS G4303 SUS310S |

Max 0.08 |

Max 1.50 |

Max 2.00 |

0.045 |

0.03 |

19.0-22.0 |

24.0-26.0 |

|

|

| JIS G4105 SCM 435 |

0.33-0.38 |

0.15-0.35 |

0.60-0.85 |

0.030 |

0.03 |

|

0.90-1.20 |

0.15-0.30 |

| JIS G4105 SCM 440 |

0.38-0.43 |

0.15-0.35 |

0.60-0.85 |

0.030 |

0.03 |

|

0.90-1.20 |

0.15-0.30 |

| JIS G4107 SNB 5 |

Min 0.10 |

Max 1.00 |

Max 1.00 |

0.040 |

0.03 |

|

4.00-6.00 |

0.40-0.65 |

|

| JIS G4107 SNB 7 |

0.38-0.48 |

0.20-0.35 |

0.75-1.00 |

0.040 |

0.04 |

0.80-1.10 |

0.15-0.25 |

| JIS G4107 SNB 16 |

0.36-0.44 |

0.15-0.35 |

0.45-0.70 |

0.040 |

0.04 |

0.80-1.15 |

0.50-0.65 |

| JIS G4051 S45C |

0.42-0.48 |

Max 0.40 |

0.60-0.90 |

0.040 |

0.035 |

|

|

| ASTM A194 Gr 2H |

Min 0.40 |

Max 0.40 |

Max 1.00 |

0.040 |

0.05 |

|

|

|

|

| ASTM A194 Gr 2HM |

Min 0.40 |

0.15-0.35 |

Max 1.00 |

0.040 |

0.05 |

|

|

| ASTM A194 Gr 7M |

0.37-0.49 |

0.15-0.35 |

0.65-1.10 |

0.040 |

0.04 |

0.75-1.20 |

0.15-0.25 |

| ASTM A194 Gr 4 |

0.40-0.50 |

0.15-0.35 |

0.70-0.90 |

0.035 |

0.04 |

|

0.20-0.30 |

| ASTM A194 Gr 7 |

0.37-0.49 |

0.15-035 |

0.65-1.10 |

0.040 |

0.04 |

|

0.75-1.20 |

0.15-0.25 |

|

| ASTM A194 Gr 8 |

Max 0.06 |

Max 1.00 |

Max 2.00 |

0.045 |

0.03 |

8.00-10.5 |

18.0-20.0 |

|

| ASTM A194 Gr 8M |

Max 0.08 |

Max 1.00 |

Max 2.00 |

0.045 |

0.03 |

10.0-14.0 |

16.0-18.0 |

2.00-3.00 |

| ASTM A563 Gr A.B.C |

Max 0.55 |

|

|

0.012 |

0.15 |

|

|

|

|

| ASTM A563 Gr Gr D |

Max 0.55 |

Min 0.30 |

0.040 |

0.05 |

| ASTM A563 gR Gr DH |

0.20-0.55 |

Min 0.60 |

0.040 |

0.05 |