API 6ACRA Stud Bolt ASTM B637 UNS N07718,Inconel 718 hex bolt

China Manufacturer of API 6ACRA STUD Bolt and Nut ASTM B637 UNS N07718 Inconel 718

N07718, Alloy 718, often referred to as Inconel 718, is a high-strength, corrosion-resistant nickel chromium alloy supplied in the hot worked, solution annealed and age hardened condition.

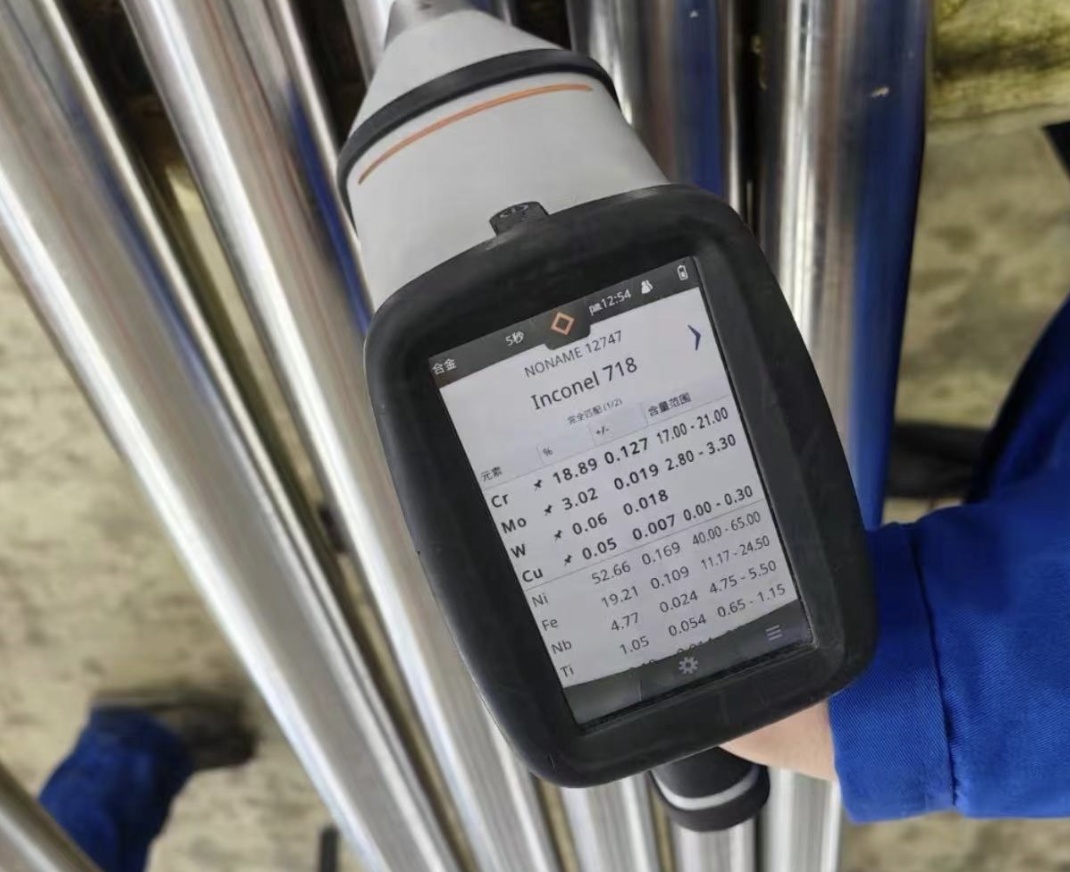

N07718 stud bolts are manufactured from Inconel 718, a precipitation-hardened nickel-based alloy. The unique composition of this alloy includes:

- Nickel (50-55%): Provides outstanding corrosion resistance.

- Chromium (17-21%): Enhances oxidation resistance.

- Molybdenum & Niobium: Improve strength and stability under stress.

- Iron, Titanium, and Aluminum: Further strengthen the alloy’s properties.

These bolts are renowned for their high tensile and yield strength, even in extreme temperatures ranging from cryogenic levels up to 700°C (1290°F).

N07718 bolt Chemical composition:

| Alloy | % | Ni | Cr | Fe | Mo | Nb | Co | C | Mn | Si | S | Cu | Al | Ti |

| inconel 718 | Min. | 50 | 17 | balance | 2.8 | 4.75 | 0.2 | 0.7 | ||||||

| Max. | 55 | 21 | 3.3 | 5.5 | 1 | 0.08 | 0.35 | 0.35 | 0.01 | 0.3 | 0.8 | 1.15 |

N07718 Stud bolt mechanical properties

in the room temperature:

| Alloy | Tensile strength Rm N/mm² |

Yield strength R P0. 2N/mm² |

Elongation A 5 % |

Brinell hardness HB |

| Solution treatment | 965 | 550 | 30 | ≤363 |

Standards and Specifications

N07718 stud bolts are manufactured to meet industry standards, including:

- ASTM B637: Covers age-hardened Inconel 718 fasteners.

- ASME and API Standards: API 6ACRA

Inconel 718/N07718 Stud bolt Heat treatment

Two heat treatments are generally utilized for INCONEL alloy 718: •Solution anneal at 1700-1850°F followed by rapid cooling, usually in water, plus precipitation hardening at 1325°F for 8 hours, furnace cool to 1150°F, hold at 1150°F for a total aging time of 18 hours, followed by air cooling.

Inconel 718/N07718 Stud bolt character

- Good strength/ductility properties from sub-zero temperatures to over 750°C

- Acceptable corrosion resistance and fatigue resistance in a wide variety of corrosive chemicals such as seawater and industrial acids

- Non-magnetic and spark resistant

- Excellent resistance to stress corrosion cracking, chloride stress corrosion & sulphide stress cracking

- High fatigue strength in seawater

Inconel 718/N07718 Stud bolt Applications:

- Oil & Gas industry wellhead components, gate valves, choke stems, fasteners, packers, clamps, tubing hangers, downhole equipment

- Power generation applications such as fasteners, turbines

- Aerospace components

- Nuclear power plant containment vessels, valves

- Engineering applications between 750°C and cryogenic temperatures

Benefits of N07718 Stud Bolts

- Long-lasting performance in aggressive environments.

- Resistant to fatigue and creep deformation.

- Complies with stringent industry standards (e.g., ASTM B637).

Inconel 718 (N07718) Stud bolts are manufactured in nominal diameters ranging from 1/8”- 3” (M3 – M80). We offer Inconel 718 (N07718) fasteners in both USCS/Imperial and metric sizes.