DUPLEX STAINLESS STEEL UNS S31803 and S32205 are the most common grade in duplex steel materials.

Both are widely used in industries requiring high strength and excellent corrosion resistance.

UNS S31803 or 2205 Duplex is a super austenitic premium stainless grade that exudes high corrosion resistance. The name comes from the chemical make-up of 22% Chrome and 5% Nickel. 2205 Stainless was originally created for the pulp and paper to counter act harsh chemicals and chlorides. It is now prevalent in many industries as a more cost-efficient alloy in lieu of higher nickel grades.

What is UNS S32205?

UNS S32205 is an enhanced version of duplex stainless steel, designed for superior performance in harsh environments. It features a balanced microstructure of austenite and ferrite, providing exceptional mechanical strength and improved resistance to pitting and crevice corrosion. This grade is particularly suited for chloride-rich environments, such as offshore, chemical processing, and marine applications.

What is UNS S31803?

UNS S31803, often referred to as 2205, is the original duplex stainless steel developed for high-performance applications. Known for its excellent combination of strength and corrosion resistance, it is widely used in chemical processing, oil and gas, and other industrial sectors. While effective, it lacks some of the refinements found in S32205.

Differences Between UNS S32205 and UNS S31803

- Chemical Composition

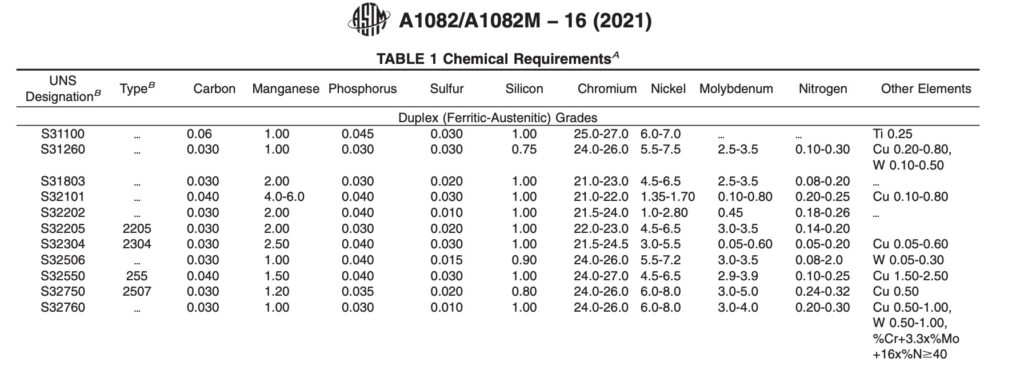

- UNS S31803: Contains approximately 22% chromium, 5-6% nickel, 3% molybdenum, and moderate nitrogen levels.

- UNS S32205: Features slightly higher nitrogen content and more tightly controlled alloying elements, leading to enhanced properties.

- Corrosion Resistance

- UNS S31803: Provides good resistance to general corrosion, stress corrosion cracking, and pitting in moderate environments.

- UNS S32205: Offers superior resistance to pitting and crevice corrosion, especially in aggressive chloride environments, making it a better choice for demanding applications.

- Mechanical Strength

- S31803: Known for excellent tensile and yield strength, outperforming many austenitic stainless steels.

- S32205: Delivers even higher strength due to its optimized composition, making it suitable for high-stress conditions.

The main difference between UNS S32205 and UNS S31803 lies in their performance in aggressive environments. S32205 offers improved mechanical properties and better resistance to localized corrosion, making it the ideal choice for demanding applications. S31803, on the other hand, is a reliable and economical option for moderate conditions

Material Availability

Bar, forgings, sheet, plate, pipe, tube, closed die forgings,flanges and welding consumables.

ASME SA-182, SA-240, SA-798, SA-790, SA-815

ASTM A182, A240, A276, A479, A789, A790, A815, A928, A988