Xylan 1424 COATED STUD BOLTS AND HEX NUTS

Xylan 1424 Coated Stud Bolts are fasteners coated with Xylan 1424, a high-performance fluoropolymer coating that provides outstanding protection against corrosion, friction, and wear. This makes them ideal for use in harsh environments where durability and long-term performance are critica

xylan_1424

Xylan® 1424 series coating is a high performance, waterbourne, VOC compliant material that is resin-bonded, thermally cured, single film dry lubricant. It is excellent at protecting against chemicals, corrosive agents, extreme weather,and abrasives.

Xylan® 1424 is primarily formulated for use on fasteners to prevent corrosion and facilitate make-up and break-out torque.

Xylan® 1424 coating can be applied to many types of substrate materials such as aluminum, brass, high alloy steel, carbon steel, stainless steel, titanium, and Zinc plating.

Xylan® 1424 coatings will withstand most solvents,waters, automotive fluids, and fuels.Xylan® 1424 is impervious to new water based hydraulic

fluids used in offshore oil production.

Xylan® 1424 eliminates the problems of galling, a form of wear due to excessive friction between two moving surfaces, which occurs with metals such as stainless steel.Coefficient of Friction & Torque Values Xylan® 1424 coating has a low coefficient of friction,typically in the range of 0.05 to 0.10. This reduces the torque required to achieve the desired tension preload.

Applications:

- Offshore Oil and Gas: Stud bolts exposed to seawater or harsh conditions benefit from Xylan 1424’s corrosion protection.

- Chemical Processing: The coating’s chemical resistance is vital in refineries, petrochemical, and pharmaceutical industries.

- Marine: The protection against saltwater corrosion makes it ideal for use in shipbuilding or offshore platforms.

- Automotive and Aerospace: In applications requiring high-performance and durability, Xylan 1424 coated stud bolts offer resistance to wear and corrosion.

stud bolt is a type of fastener commonly used in industries where heavy-duty and high-strength connections are needed, such as in construction, piping, petrochemical, and offshore oil & gas sectors.

Threading:

Stud bolts have full-length threading on both ends, which allows them to be screwed into nuts or threaded parts at both sides. The length of the thread can vary based on the requirements of the connection

Stud Bolt Material which could be applied for Xylan 1424 coating

Carbon Steel

- Grades: ASTM A307

- Applications: Low-pressure and low-temperature environments.

Alloy Steel

- Grades: ASTM A193 B7, B7M

- Xyan 1424 coated ASTM A193 B7 stud bolt,Xyan 1424 coated ASTM A193 B7M stud bolt,

- Applications: High-temperature and high-pressure environments, such as refineries and chemical plants.

Stainless Steel

- Grades: ASTM A193 B8 (304), B8M (316), Duplex grades

- Applications: Corrosive environments, including marine and chemical industries.

Nickel Alloys

- Grades: ASTM B637 (Inconel 718), ASTM F468 (Monel 400)

- Applications: Extreme conditions, such as high temperatures and aggressive chemical environments.

Low-Temperature Carbon Steel

- Grades: ASTM A320 L7, L7M

- Xyan 1424 coated ASTM A320 L7 stud bolt,Xyan 1424 coated ASTM A320 L7M stud bolt

- Applications: Cryogenic and low-temperature environments, such as LNG plants.

Precipitation-Hardening Steels

- Grades: ASTM A453 Grade 660 (Classes A, B, C, D)

- Applications: High-temperature environments where creep resistance is critical.

Xylan FAQ

1.What is Xylan?

Xylan is a family of fluoropolymer coatings designed by Whitford to provide corrosion protection, lubrication, wear resistance and non-stick properties in a variety industries and applications.

2,Difference tween Xylan 1424 and Xylan 1070?

Xylan 1424 – Xylan 1424 is a water-resistant, low-friction coating with relatively high resistance to abrasion, chemical degradation and corrosion. These attributes make Xylan 1424 especially ideal for caustic environments. This type of coating is also VOC-compliant for environmentally sensitive and sustainable applications.

Xylan 1070 – Like Xylan 1424, Xylan 1070 is water-resistant, has a low coefficient of friction, and also possesses formidable corrosion and heat resistance. This PTFE coating is ideal for leak prevention in tanks, vessels and valves operating in relatively aggressive environments. (For more information on protecting process vessels, read Introduction to Managing Internal Corrosion in Process Vessels.

3 How do you apply Xylan Coating?

Xylan coatings require meticulous pre-treatment, application and curing processes, therefore must be applied by an experienced applicator, preferably with QAC (Quality Approved Coater) certification.

Our xylan coating procedure.

1: Applying a base-coat such as Phosphate, Zinc, Zinc-Nickel, Hot Dip Galvanized or Xylar 1. The base coat has an average thickness of 10-15µ (except for HDG).

2, Glass-shot blasting to roughen the surface of the fasteners to be coated.

3,Having fasteners coated with PTFE Xylan 1070 or Xylan 1424 in the required color. See the table below for the top coat most suited to for your situation.

4: Heat treatment of the coated fasteners is performed.

4.Is Xylan the same as PTFE Coating?

Generally,yes… Xylan is one kind of PTFE (Polytetrafluoroethylene) coatings.

5.Do you supply Xylan coated fasteners?

Yes. Amongst the Xylan range are a series of fastener-class coating systems designed to improve the performance and longevity of all types, sizes and grades of fasteners through its excellent corrosion resistant and low-friction properties. Xylan can be applied via dip-spin and spray methods, meaning it is suitable for small screws right through to large stud bolts.

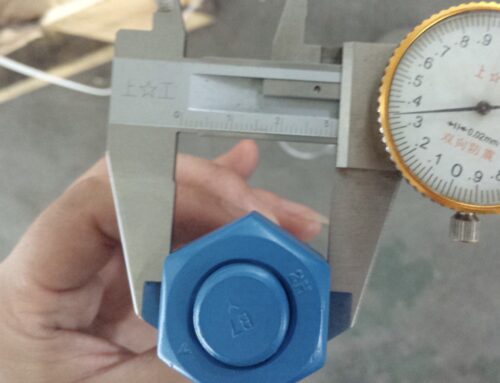

6.What is Xylan Blue?

Xylan actually comes in a wide range of colours but is often referred to as “Xylan Blue” or “PTFE Blue” in reference to coating B7 Stud Bolts and Nuts for the Petrochemical industry. Generally, the most popluar PTFE Coating material for the stud bolt and nuts are Xylan 1424 and Xylan 1070

7.What are the addtional coating type you can supply?

Zinc + Fluorocarbon / PTFE

Cadmium + Fluorocarbon /PTFE

Zinc Nickel + Fluorocarbon /PTFE

Zinc Plating + Xylan 1424 Blue

Xylar 2 + Xylan 1070 Blue

Xylar 2 + xylar 101 coated stud bolt

8.Xylan 1424 coated stud bolts order information.?

Stud Bolt 1″x180mm + 2 Heavy Hex Nuts ASME B18.2.1/B18.2.2/B1.1 Cl.2A/2B ASTM A 193 Gr.B7 – A 194 Gr.2H Fluorocarbon Coated blue color