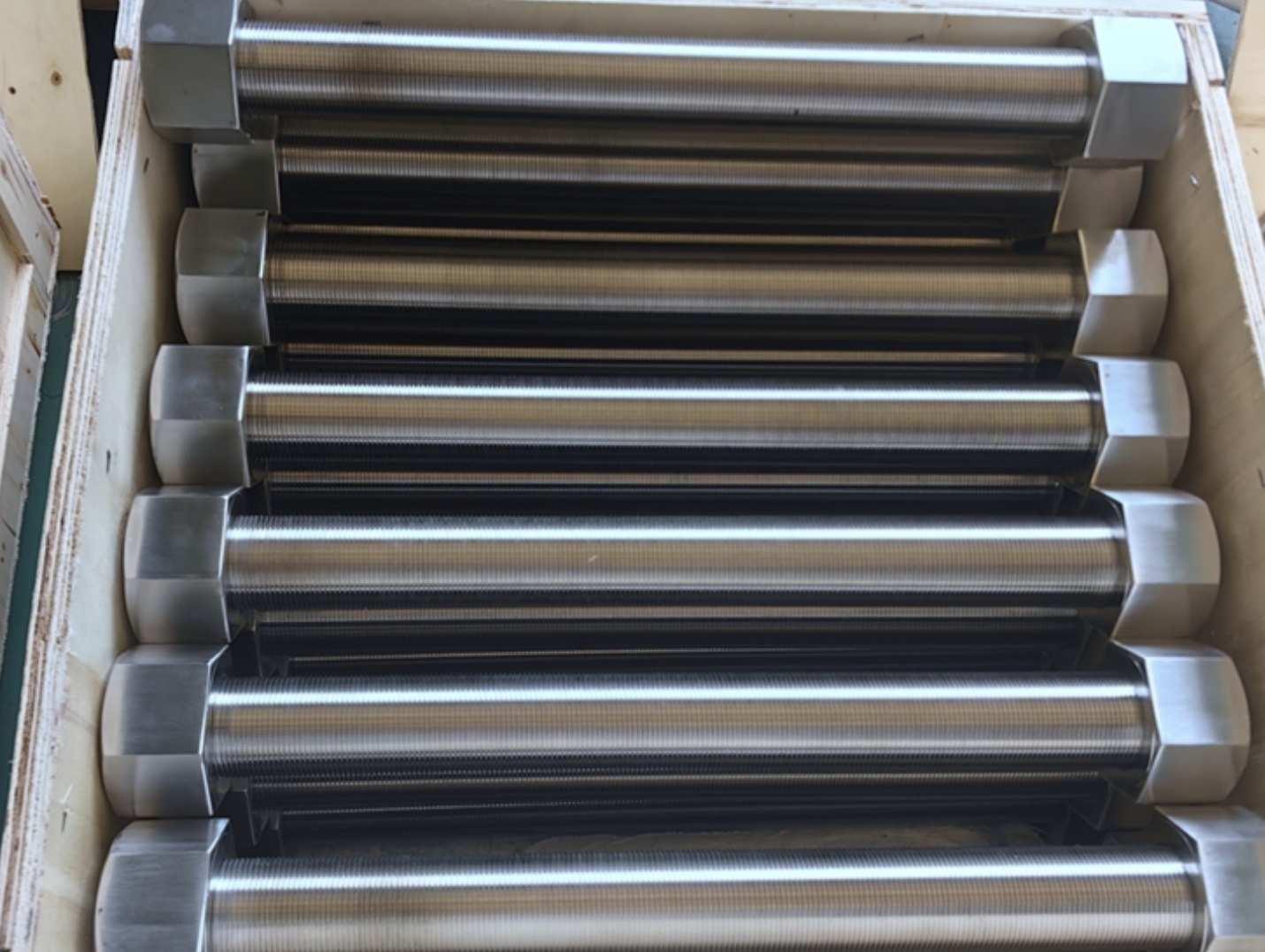

China Professional Manufacturer of 1.4410 Uns S32750 STUD BOLT F53 SUPER Duplex 2507 DIN975 Threaded Rod

S32750 (1.4410) Super Duplex Stainless Steel

UNS S32750 is a duplex stainless steel especially designed for service in aggressive chloride-containing environments. It has very good resistance to localized corrosion and stress corrosion cracking in combination with high mechanical strength. It is widely used in oil & gas, hydropower, pressure vessels, pulp & paper, structural components and chemical tankers.

Super Duplex stainless steel, relative to other stainless steel products, gives:

• High corrosion resistance

• High resistance to stress corrosion cracking

• High yield strength and tensile strength

UNS S32750 Chemical Composition (% max or range).

| C | Mn | P | S | Si | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| 0.03 | 1.20 | 0.035 | 0.02 | 0.80 | 24.0 – 26.0 | 6.0 – 8.0 | 3.0 – 5.0 | 0.24 – 0.32 |

UNS S32750 Mechanical properties

| Tensile | Yield | Elongation | Hardness |

|---|---|---|---|

| MPa min | MPa min | % min | Brinell max |

| 795 | 550 | 15.25% | 310 |

UNS S32750 Grade Bolts Equivalent Material

| STANDARD | ASTM | ASME | UNS | WERKSTOFF NR. |

| Super Duplex 2507 | A276/ A479 | SA 276/ SA 479 | S32750 | 1.4410 |

Heat Treatment

Solution annealing at 1100°C followed by water quenching

1.4410 Uns S32750 STUD BOLT Specification

Material: 1.4410 Uns S32750 F53 SUPER Duplex 2507

Bolt and Nut Standards

ISO 4014, ISO 4017, ISO 4033, ISO 261

DIN 938, DIN 939, DIN 940, DIN 975, DIN 976, DIN 2510, DIN 931, DIN 933, DIN 126, DIN 732, DIN 934

ASME B18.2.1 ASME B18.2.3.5M, ASME B18.2.6M, ASME B18.31.2M, ASME B18.22.1, ASME B18.2.2, ASME B18.2.4.1M, ASME B18.2.4.2M, ASME B18.2.4.6M

ANSI B18.2.1, ANSI B18.2.3.5M, ANSI B18.2.6M, ANSI B18.31.2M, ANSI B18.22.1, ANSI B18.2.2, ANSI B18.2.4.1M, ANSI B18.2.4.2M, ANSI B18.2.4.6M

Available Sizes of S32750 Stud bolt

Diameter: M6 – M100 (1/4” – 4”)

Length: 25mm – 3000mm (1” – 118”)

Thread Type: Full Thread, Partial Thread, UNF, UNC, Metric

Coating Options: PTFE, Xylan,

PTFE coated, TEFLON coated, XYLAN coated

Colors: blue, green, red,

Applications of S32750 Stud Bolts

Oil & Gas Industry – Used in offshore rigs, pipelines, and refinery systems.

Chemical & Petrochemical Plants – Handles highly corrosive chemicals and acids.

Marine & Shipbuilding – Resistant to seawater corrosion in marine environments.

Power & Desalination Plants – Performs well in high-temperature and chloride-rich conditions.

Heat Exchangers & Pressure Vessels – Ensures durability in extreme pressure applications.

S32750 Stud Bolt – High-Strength Super Duplex Fasteners

S32750 Stud Bolts are made from super duplex stainless steel, offering exceptional strength, corrosion resistance, and durability in harsh environments. These fasteners are widely used in offshore, marine, chemical, and oil & gas industries, where resistance to chloride stress corrosion, pitting, and crevice corrosion is essential.