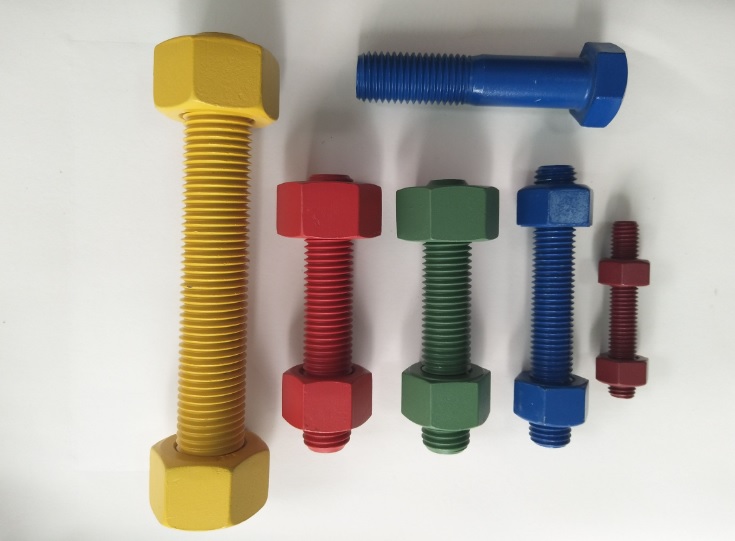

We are a professional manufacturer of Zinc plated with xylan 1424 green PTFE coated A320-L7 Stud bolt in China

A PTFE coated ASTM A320 L7 stud bolt is a high-strength fastener designed for low-temperature applications, protected with a PTFE (Polytetrafluoroethylene) coating to enhance its performance in corrosive and extreme environments.

Stud bolts ASTM A320 Gr L7

Alloy steel, AISI 4140/4142 Quenched and tempered, the specification covers alloy steel bolting materials for low temperature service and intended for use for pressure vessels, valves, flanges, and fittings.

Material: ASTM A320 GRADE L7

Coating: PTFE/ GALVANIZING/H.D.G/ELECTRO PLATING/BLACK

Dimensional Standard: ANSI/ASME B1.1

Available Diameter : 1/2″ TO 4″

ASTM A320 Grade L7 Stud bolt is manufactured from alloy steel, quenched and tempered. Dimensional specifications are governed by ASME B18.31.3. Inch series fasteners meeting ASTM A320 Grade L7 specifications are typically used to secure valves, flanges and fittings in low temperature applications. A320 L7 all thread rod having diameters above 1″ are most common 8UN (8 threads per inch).

| ASTM A320 Grade L7 Chemical Composition Note | ||

| Elements | Range | Variation, % |

| Carbon | 0.08 max | 0.01 over |

| Manganese | 2.00 max | 0.04 |

| Phosphorus, max | 0.04 max | 0.005 over |

| Sulfur, max | 0.03 max | 0.005 over |

| Silicon | 1.00 max | 0.05 |

| Nickel | 24.00 – 27.00 | 0.20 |

| Chromium | 13.50 – 16.00 | 0.20 |

| Molybdenum | 1.00 – 1.50 | 0.05 |

ASTM A320 Grade L7 Mechanical Properties

ASTM A320 Grade L7 Mechanical Properties for Metric and Imperial units. All intermediary or finished products manufactured to ASTM A320 Grade L7 specification must comply with tensile strength; yield strength, elongation, reduction or area and hardness as per below requirement. This requirement is achieved by hardening AISI 4140, 4145, 4145, 4140H, 4142H or 4145H alloy steel followed by tempering at temperatures specified below.

Heat Treatment

| Quenching (Hardening) & Tempering | 1100º F [593º C] minimum |

Mechanical Properties

| Diameter, inch[mm] | Tensile Strength, min, ksi [Mpa] | Yield strength, min, ksi, [Mpa] | Elongation in 2 inch. Or 50mm, min, % | Reduction of Area, min, % | Hardness, max |

| 2-1/2″ [65] | 125 [860] | 105 [725] | 16 | 50 | 321 HB or 35 HRC |

Note : These upper diameter limits were established on the basis that these were the largest sizes commonly available that consistently met specification property limits. They are not intended as absolute limits beyond which bolting materials could no longer be certified to the specification.

V-Notch Charpy Impact Test Requirements

| Test Temperature | Size of Specimen, mm | Minimum Impact Value Required for Average of Each Set of Three Specimens, ft-lbf [J] | Minimum Impact Value Permitted for One Specimen Only of a Set, ft-lbf [J] | |

| -150º C | -101º C | 10 by 10 | 20 [27] | 15 [20] |

| 10 by 7.5 | 16 [22] | 12 [16] |

We can provide xylan 1424 green PTFE coated A320-L7 Stud bolts

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene. Being hydrophobic, non-wetting, high density and resistant to high temperatures, PTFE is an incredibly versatile material with a wide variety of applications, though it’s perhaps best-known for its non-stick properties.

Xylan coatings including 1014, 1052, 1070, 1400, 1424, and 1425. Xylan is typically used in non-stick applications to reduce friction while improving wear resistance caused by the fluoropolymers and binding resins that make up the composition. Xylan, itself, is able to withstand heavy loads and high temperatures and is known for its’ flexible curing schedule, machinability, corrosion resistance, and adhesion capabilities.

Xylan 1424 Coating stud bolts

Main Properties

Dry film lubricant. Corrosion resistant.

Typical Applications

Any mating surface which requires lubrication. Hinge pins. Piston casing. Compressors. Threaded fasteners.

Color available

Black, Green, Blue, Haze Gray