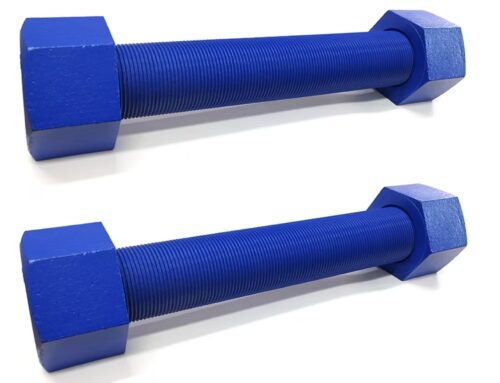

PTFE Fluorocarbon xylan 1070 coated Astm a193 B7 Stud bolts

As a leading manufacturer and exporter in China, we specialize in providing Xylan 1070 coated ASTM A193 B7 stud bolts. These fasteners are designed for high-temperature, high-pressure, and corrosive environments, ensuring enhanced durability and performance. Xylan 1070, a fluoropolymer coating, offers superior protection against wear, corrosion, and chemical exposure, making it an ideal choice for demanding industrial applications.

What Are Xylan 1070 Coated ASTM A193 B7 Stud Bolts?

Xylan 1070 Coated ASTM A193 B7 Stud Bolts are fasteners made from ASTM A193 B7 material, which is alloy steel, and coated with Xylan 1070, a high-performance fluoropolymer coating (often referred to as PTFE or Teflon). This coating significantly improves the corrosion resistance, lubricity, and high-temperature performance of the fasteners, extending their lifespan in industries such as oil & gas, chemical processing, and marine environments.

Key Features of Xylan 1070 Coating

- Fluoropolymer-based PTFE coating for superior chemical and corrosion resistance.

- Ideal for use in high-temperature and high-pressure environments.

- Reduces friction, prevents galling, and enhances sealing properties.

- Available in multiple colors, including Dark Blue, Green, Yellow, and Red.

- Coating thickness typically ranges from 15-20 microns, ensuring optimal protection.

Applications of Xylan 1070 Coated ASTM A193 B7 Stud Bolts

Xylan 1070 coated ASTM A193 B7 stud bolts are commonly used in the following applications:

- Oil and Gas: High-pressure pipelines, heat exchangers, and pressure vessels.

- Chemical Processing: Systems exposed to aggressive chemicals and corrosive environments.

- Marine and Offshore: Platforms, subsea equipment, and applications with high salt exposure.

Xylan 1070 Coating Process for Stud Bolts

The Xylan 1070 coating process involves multiple steps to ensure maximum performance and durability:

- Base-coat application (Phosphate, Zinc, Zinc-Nickel, or Xylar 2) with a thickness of 10-15 microns.

- Surface preparation using glass-shot blasting to roughen the fastener surface.

- Application of the Xylan 1070 (or Xylan 1424) coating on top for a durable, corrosion-resistant finish.

- Oven heat Curing.

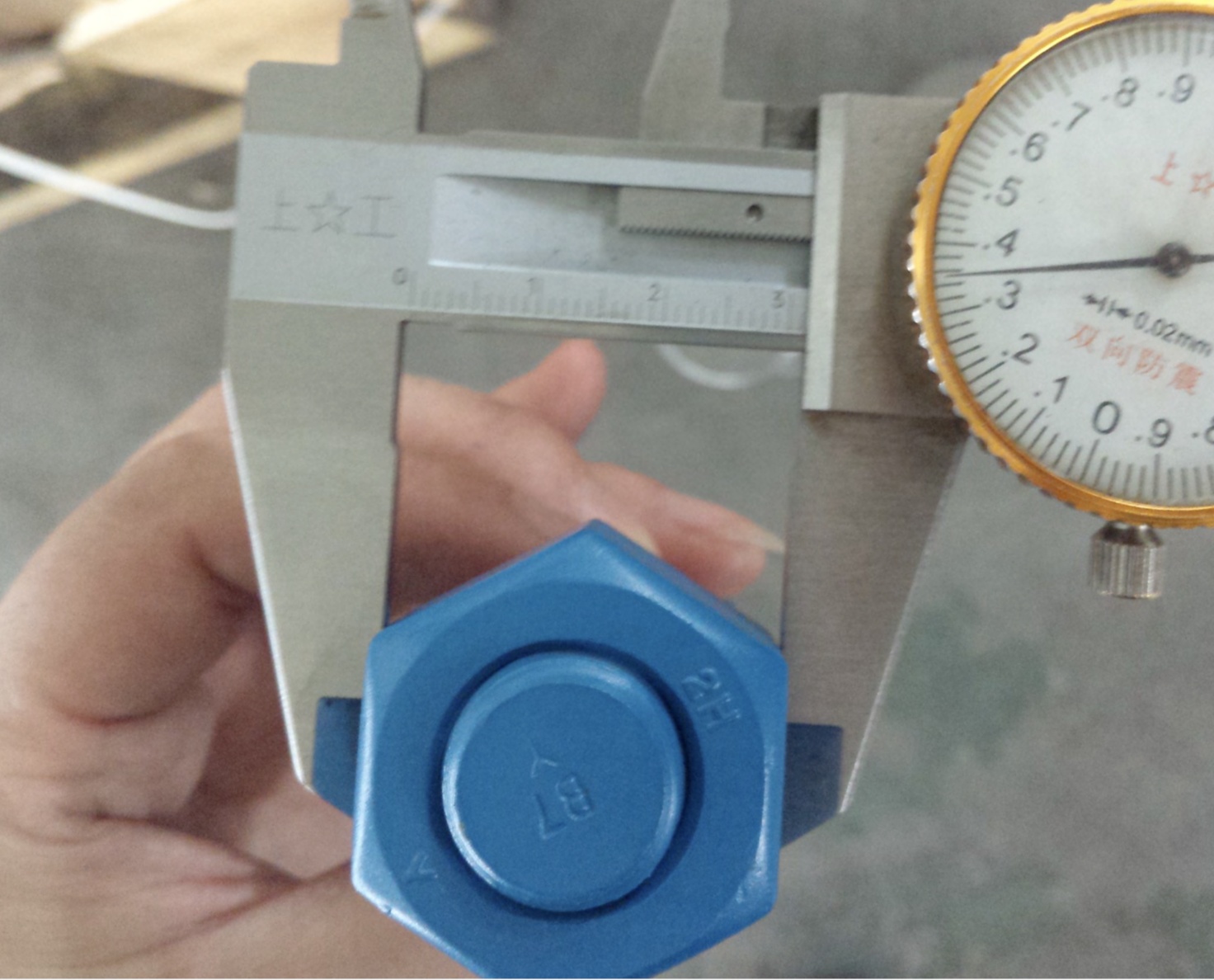

Sample Order Specifications for Xylan 1070 Coated ASTM A193 B7 Stud Bolts:

-

Stud Bolt: 3/4″ x 5-1/2″ (140mm) with 2 pcs Heavy Hexagonal Nuts, Full Threaded

Material: ASTM A193 Grade B7

Nut Material: ASTM A194 Grade 2H

Coating: Xylan 1070 required

Quantity: 300 pcs

Chemical Composition Of Astm A193 Grade B7 Stud Bolts

| C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.37-0.49 | 0.65-1.10 | 0.15-0.35 | 0.035 | 0.04 | 0.75-1.20 | 0.15-0.25 |

A193 B7 Stud bolt mechanical properties

Xylan 1070 coated ASTM A193 B7 stud bolt Specifications

| Parameter | Details |

|---|---|

| Material Grade | ASTM A193 B7 |

| Coating | Xylan 1070 Blue |

| Thread Type | UNC (coarse) or UNF (fine) |

| Size Range | 1/4″ to 4″ (M6 to M100 metric) |

| Length | Standard and custom lengths |

| Nuts and Washers | Heavy hex nuts per ASTM A194 2H |

Xylan 1070 Coating vs. Xylan 1424 Coating

While both Xylan 1070 and Xylan 1424 coatings provide excellent protection, Xylan 1070 is specifically designed for higher temperature resistance and greater corrosion protection, making it suitable for applications in industries like oil & gas and power generation. On the other hand, Xylan 1424 is often preferred for more general applications requiring moderate temperature resistance and chemical protection.

Difference Between ASTM A193 B7 and ASTM A320 Grade L7 Stud Bolts

While both ASTM A193 B7 and ASTM A320 Grade L7 stud bolts are high-strength fasteners made from chromium-molybdenum steel, they are designed for different temperature ranges:

| Aspect | ASTM A193 B7 | ASTM A320 Grade L7 |

|---|---|---|

| Primary Use | High-temperature applications | Low-temperature (cryogenic) applications |

| Operating Temperature | -20°F to 1,200°F (-29°C to 650°C) | -150°F to 850°F (-101°C to 454°C) |

| Heat Treatment | Quenched and tempered | Quenched, tempered, and low-temp optimized |

| Impact Testing | Not required | Required for low-temperature toughness |

| Common Coatings | Plain, galvanized, Xylan-coated | Plain, galvanized, Xylan-coated |

- ASTM A193 Grade B7: Best suited for high-temperature and high-pressure environments.

- ASTM A320 Grade L7: Best suited for low-temperature and cryogenic applications.

So the using enviorement and temperaratur condition is the key factor to consider when you select the material between ASTM A193 B7 and ASTM A320 Grade L7 Stud Bolts

Why Choose Xylan 1070 Coated ASTM A193 B7 Stud Bolts?

- Superior Corrosion Resistance: Ideal for harsh environments.

- Enhanced Durability: Extended service life in high-temperature and high-pressure settings.

- Improved Performance: PTFE coating reduces friction, preventing galling and thread damage.

- Wide Application Range: Suitable for oil & gas, chemical processing, marine, and power generation industries.

Contact us today to request a quote for Xylan 1070 coated ASTM A193 B7 stud bolts.