We are a professional manufacturer of ASTM B564 17-4PH S17400 full threaded stud bolt,Alloy 630 1.4542 Stud Bolt

The most well known precipitation hardening steel is 17-4 PH. The name comes from the additions 17% Chromium and 4% Nickel. It also contains 4% Copper and 0.3% Niobium. 17-4 PH is also known as stainless steel grade 630.

SAE Type 630 stainless steel (more commonly known as 17-4 PH, or simply 17-4; also known as UNS S17400) is a grade of martensitic precipitation hardened stainless steel. It contains approximately 15–17.5% chromium and 3–5% nickel, as well as 3–5% copper.[1] The name comes from the chemical makeup which is approximately 17% chromium and 4% nickel. SUS630 is the same as 17-4PH, and they both refer to the same grade

Alloy 17-4PH (UNS S17400), Type 630, is a chromium-nickel-copper precipitation-hardening martensitic stainless steel with an addition of niobium. 17-4PH combines high strength and hardness with good corrosion resistance.

The alloy is furnished in the solution annealed condition (Condition A). It should not be used at temperatures above 572°F (300°C) or for cryogenic service. Optimal mechanical properties can beobtained by subjecting the alloy to age hardening heat treatments. Heat treatment in the 900°F (482°C) range produces the highest strength.The corrosion resistance of Alloy 17-4PH is comparable to 304 stainless steel in most environments,and is generally superior to the 400 series stainless steels. It is used in applications where the combination of moderate corrosion resistance and unusually high strength are required.Alloy 17-4PH can be easily welded and processed by standard shop fabrication practices.

UNS S17400 Stud Bolt Specification

Standard ASTM F2281, A564 / ASME SF2281, SA564

Dimensions DIN 975/976, ASME B18.2.1, B18.31.3, B16.5

Threads Configuration ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads

Type Cold Forged, Hot Forged, Bar Stock Machined, Bar Stock Milling

Size M02 to M160

Length 3 mm to 200 mm

17-4 PH Stud Bolts

| STANDARD | UNS | WERKSTOFF NR. |

| 17-4 PH | S17400 | 1.4542 |

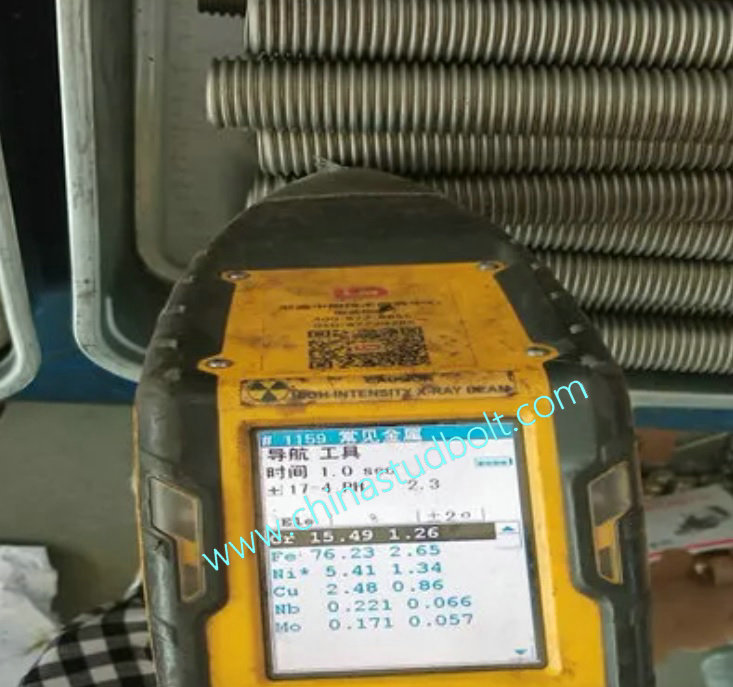

17-4PH S17400 Composition

| C | Mn | P | S | Si | Cr | Ni | Cu | Nb, Ta |

|---|---|---|---|---|---|---|---|---|

| 0.07 max. | 1.0 max. | 0.04 max. | 0.03 max. | 1.0 max. | 15.0–17.5 | 3.0–5.0 | 3.0–5.0 | 0.15–0.45 |

Heat Treatment

Alloy 17-4PH is provided in the solution-annealed condition (Condition A).Mechanical properties may be altered by subsequent age hardening treatments. These aging treatments are referred to as Conditions H900,H1025, H1075, H1150, H1150M and H1150D. The processes are outlined in Table 2 below.

FAQ for S17400 (17-4 PH) Stud Bolt

1. What is an S17400 Stud Bolt?

S17400 (also known as 17-4 PH) stud bolts are high-strength, precipitation-hardening stainless steel fasteners used in applications requiring excellent mechanical properties and corrosion resistance.

2. What heat treatment conditions are available?

S17400 stud bolts can be supplied in various heat-treated conditions:

-

H900: ~ 40-47 HRC (highest strength, slightly lower corrosion resistance)

-

H1025: Moderate strength and toughness

-

H1150: Best toughness, lower strength

3. What standards apply to S17400 Stud Bolts?

-

ASTM A564 (for bars and rods)

-

AMS 5643 / AMS 5622 (aerospace applications)

4. How to order our 17-4 PH Stud bolts,

Size:2-1/4″ – 8UN x L=8.5″ A-564 17-4 PH H1150 STUD BOLT WITH 2 HEAVY HEX NUTS

QTY:100 SETS