Xylan 1070 Coated ASTM A193 B7 Stud Bolts | PTFE Coated Fasteners for Corrosion and High-Temperature Resistance

China Leading Manufacturer and Exporter of Xylan 1070 coated ASTM A193 B7 Stud bolt– Offering Premium Fasteners for Harsh Environments.

What is Xylan 1070 Coating?

Xylan 1070 is a high-performance fluoropolymer-based coating (often referred to as PTFE or Teflon) developed by Whitford Worldwide. It is one of the most popular grades of Xylan® coatings, known for its exceptional corrosion resistance, low friction, and high durability. Xylan 1070 provides reliable protection for fasteners, especially in marine, offshore, and petrochemical applications.

Xylan 1070 Coating Benefits:

- Superior corrosion resistance: Effective protection against saltwater, harsh chemicals, and oxidation.

- Low friction: Reduces wear and tear, prevents galling, and facilitates easy assembly and disassembly.

- High-temperature stability: Can withstand temperatures ranging from -195°C to 260°C (-319°F to 500°F).

Xylan 1070 is specifically formulated to enhance leak prevention for fasteners in environments exposed to aggressive chemicals, saltwater, and extreme temperatures. Its low friction and dry lubrication properties are especially beneficial in applications such as drilling platforms and marine infrastructure.

Is Xylan 1070 the Same as Fluorocarbon Coating? (PTFE, Xylan, Teflon)

Fluorocarbon coatings are a class of coatings made from fluoropolymers like PTFE (Polytetrafluoroethylene). These coatings are known for their chemical resistance, low friction, and high-temperature stability. Xylan 1070 is a specific formulation of a fluoropolymer coating, which is solvent-based, while Xylan 1424 is water-based.

The key difference between these coatings lies in their binder systems and adhesion promoters, which contribute to their varying performance characteristics. Both coatings, however, offer excellent corrosion protection, wear resistance, and low friction properties.

How do we make the Xylan 1070 Coated Stud Bolt ?

The Xylan 1070 coating process ensures that stud bolts receive a high-performance, durable finish. Here’s the typical procedure:

- Base-Coating: Apply a base coat such as Zinc-plating, Zinc-Nickel Plating, or Zinc-Nickel to a thickness of 10-15 microns.

- Surface Preparation: Shot blasting the fasteners to roughen the surface for better coating adhesion.

- Coating: Apply the Xylan 1070 or Xylan 1424 PTFE coating to the fasteners in the desired color (e.g., blue, green).

- Heat Treatment: Cure the coated fasteners for enhanced bonding and durability.

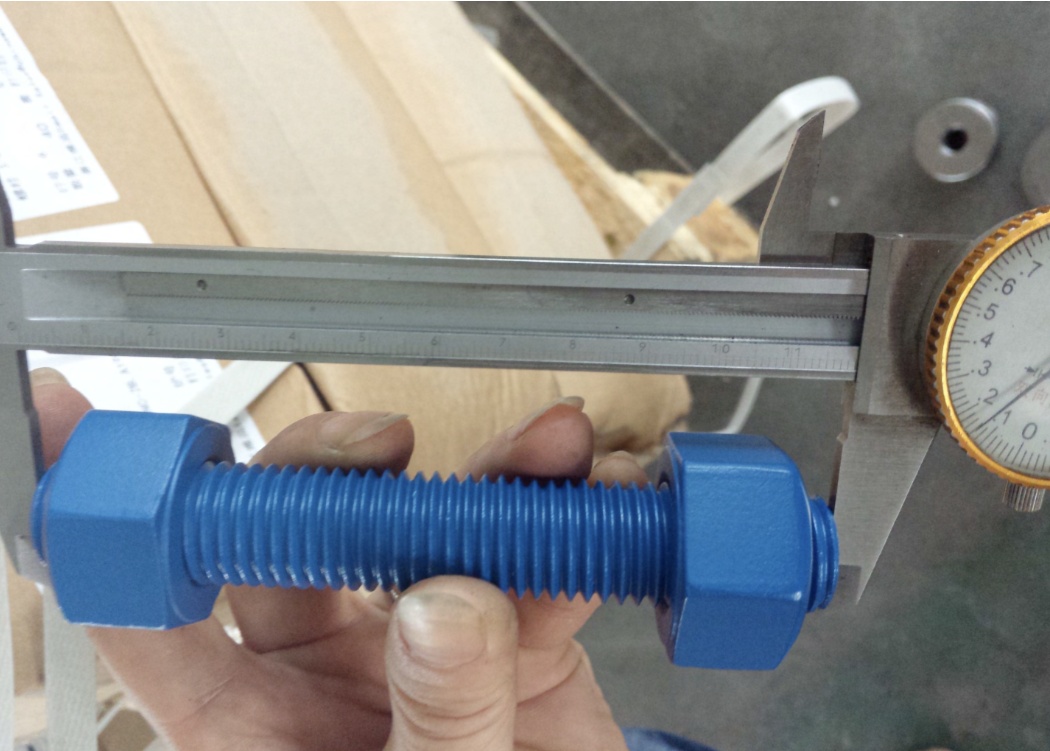

What is the Xylan 1070 Coating Thickness?

- Recommended Dry Film Thickness: 20 ± 5 microns (typical wet film thickness: 100 ± 25 microns).

- Coating Color: Common colors include blue, green, black, and yellow.

Benefits of PTFE Xylan 1070 Coated Stud Bolts

1. Exceptional Corrosion Resistance

Xylan 1070-coated fasteners provide superior protection against corrosion, making them ideal for marine, petrochemical, and offshore applications. The coating forms a protective barrier, significantly extending the service life of the bolts.

2. Galling and Seizure Prevention

The low friction properties of Xylan 1070 reduce the risk of galling, which can cause severe damage to threads. This makes assembly and disassembly easier, reducing downtime and maintenance costs.

3. High-Temperature Stability

Xylan 1070 can withstand extreme temperature ranges, from -200°C to 260°C (–328°F to 500°F), which makes it suitable for cryogenic applications as well as high-heat environments such as aerospace and automotive industries.

4. Reduced Torque and Improved Tightening

The low friction properties also reduce the required torque for fastening, leading to less stress on the threads and preventing over-tightening. This ensures a more accurate preload for a given torque, enhancing the integrity of the assembly.

5. Enhanced Durability and Longevity

Xylan 1070 coating reduces environmental wear on stud bolts, ensuring they last longer and require less frequent maintenance.

Applications of Xylan 1070 Coated Stud Bolts

- Marine: Fasteners used in shipbuilding and offshore platforms exposed to saltwater.

- Chemical Processing: Protects fasteners in environments with exposure to corrosive chemicals.

- Petrochemical & Oil & Gas: Ideal for high-stress, high-pressure systems such as pipelines and refineries.

- Automotive & Aerospace: Used for high-performance parts that require protection against wear, corrosion, and extreme temperatures.

Difference Between Xylan 1070 and Xylan 1424 Coatings.

Both Xylan 1070 and xylan 1424 are quite common coating for the fasterners.

But people might have the questions,are they the same coating?what are the differences beween Xylan 1070 and xylan 1424 ?

You may refer to below comparion table for both xylan coatings.

| Feature | Xylan 1070 | Xylan 1424 |

|---|---|---|

| Base | Solvent-based | Water-based |

| Salt Spray Resistance | Up to 3900 hours (in combination with Zinc-Nickel) | Up to 3300 hours (in combination with Zinc-Nickel) |

| Temperature Range | -195°C to 260°C (-319°F to 500°F) | -20°C to 180°C (-4°F to 356°F) |

| Common Applications | Marine, Offshore, Petrochemical | General industrial applications |

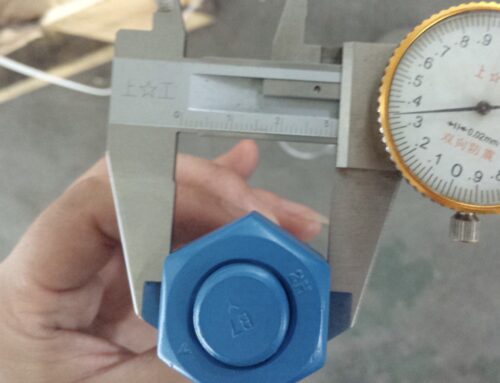

Xylan 1070 Coating Color

Xylan 1070 can be coated in a variety of colors to meet application and aesthetic requirements. Common colors include:

If no color is specified, Xylan 1070 blue coating is the default color applied.

Other color is available upon request

- Blue (standard)

- Black

- Green

- Yellow

- Olive Green

- Orange

- Red

Technical Specifications of Xylan 1070 Coated A193 B7 Stud Bolts

- Material: ASTM A193 Grade B7 Stud Bolt

- Thread Type: UNC, 8 TPI

- Nut: Heavy Hexagonal per ASME / ANSI B18.2.2

- Thread Class: 2A for stud bolts, 2B for nuts

- Design Specification: ASTM A193 for Stud Bolt, ASTM A194 for Nuts

Xylan 1070 Coated ASTM A193 B7 Stud bolt Chemical Composition %

| C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.37-0.49 | 0.65-1.10 | 0.15-0.35 | 0.035 | 0.04 | 0.75-1.20 | 0.15-0.25 |

A193 B7 Stud Bolt Mechanical Properties

| Diameter | Tensile Strength | Yield Strength | Elongation | Reduction | Hardness |

|---|---|---|---|---|---|

| M64 or Below | 860 Mpa | 720 Mpa | 16 | 50 | 321 HB |

| M64 to M100 | 795 Mpa | 655 Mpa | 16 | 50 | 321 HB |

| M100 to M180 | 690 Mpa | 515 Mpa | 18 | 50 | 321 HB |

Heavy Hex Nuts for Xylan 1070 Coated A193 B7 Stud Bolts

Normally 2 hex nuts is required for pairing with 1 stud bolts. but some cases,it could be 3 or 4 nuts for each stud bolt.

Hex nuts ASTM A194 grade 2H is standard grade for A193 B7 Stud Bolts

The stud bolt and nuts should be with the same coating.if the stud bolt with Xylan 1070 coating.

The Heavy Hex nuts should be with Xylan 1070 too.

How to Prevent Bolt Corrosion in Marine Environments(offshore)?

Want to get the pricing list for the Stud bolts ASTM A193 GR.B7 and nuts ASTM A194 GR.2H, Xylan 1070 coated?

Pls make sure you specify the Stud bolt grade B7,and Hex nuts grade 2H,the stud bolt size and length.

The most important thing is to state the coating on the fasterners:PTFE ,Xylan 1070 blue coating.

Below is the example of the Ordering Specifications for Xylan 1070 Coated Stud Bolts A193 B7 with Heavy hex nuts A194 2H

-

Stud Bolt: 2-1/2″ Dia x 470mm Long, Fully Threaded

Material: ASTM A193 Grade B7, Coating: Zinc Plating + Xylan 1070

Quantity: 100 pcs -

Stud Bolt: 1-1/2″ Dia x 170mm Long, Fully Threaded

Material: ASTM A193 Grade B7, Coating: Zinc-Nickel + Xylan 1070

Quantity: 50 pcs