We are the professional manufacturer of FCC PTFE Xylan 1424 Coated Threaded Stud Bolt A193 B7 Stud bolt in China

Fluorocarbon Coating (PTFE, Xylan, Teflon )

Fluorocarbon Coating is an organic coating consisting of solid lubricant dispersed in an organic binder and dissolved in a specially formulated mixture of solvents. It is also corrosion-resistant due to the use of a thermally cured thermosetting synthetic binding material. When applied to the substrates it resists galling, seizure and fretting and offers corrosion resistance.

Features:

Fluorocarbon Coated Stud bolts has the following characteristics:

– It is a lustrous coating.

– It has excellent adhesion.

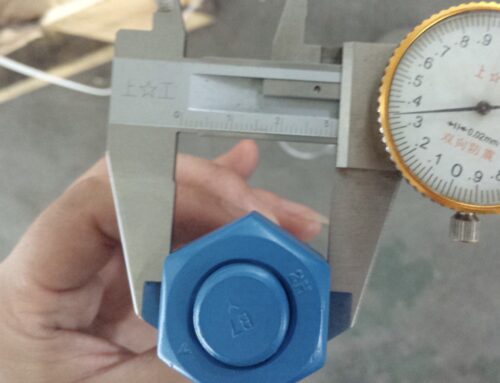

– The effective optimum film thickness is 15-25 microns.

FCC, fully written as Fluorocarbon coating,also known as PTFE coating, (Polytetrafluoroethylene), the original fluoropolymer, is a tough yet flexible, material with great electrically insulating properties and excellent resistance to chemicals; it has one of the lowest coefficients of friction of any solid. PTFE coating is also referred to as Xylan® or Teflon®

Xylan® 1424 is an environmentally-friendly, waterborne VOC compliant coating that reduces make-up and break-out torque by up to 70%. Similar to Xylan® 1014, this waterborne, low friction coefficient lubricant has high resistance to abrasion and corrosion, and is ideal for caustic environments

Xylan 1424 system is primarily designed for stud bolts and other fasteners, potential applications are

limitless. Common applications which have proven their cost advantages include:

Stud Bolts and nuts

Structural nuts and bolts

All other types of threaded fasteners*

Other small components such as springs, stampings, etc.

- Some care must be exercised with finely threaded/toleranced fasteners due to coating thickness

XYLAN 1424 coated Stud bolt production procedure

STEP ONE: Applying a base-coat such as Zinc-plating, Zinc-Nickel. The base coat has an average thickness of 10-15µ

STEP TWO: sand-shot blasting to roughen the surface of the fasteners to be coated.

STEP THREE: Having fasteners coated with PTFE Xylan 1070 or Xylan 1424 in the required color. See the table below for the top coat most suited to for your situation.

| Top coat | Comments: | ASTM B-117 Salt Spray test | Working Temperature |

| Xylan 1424. | Fluoropolymer Organic. Water-based. Average thickness topcoat: 16µ. | *In combination with Zinc-Nickel: up to 3300 hours | -20℃ to 180℃ |

| Xylan 1070 | Fluoropolymer Organic. Solvent-based. Average thickness topcoat: 16µ. | *In combination with Zinc-Nickel: up to 3900 hours | -195℃ to 260℃ |

STEP FOUR: Heat treatment of the coated fasteners is performed.

Benefits of PTFE Xylan 1424 coated Stud bolts

- Anti-Rust. In a ASTM B-117 Salt Spray test the coating remains resistant up to 3900 hours before red rust occurs.

- Sustainability. As we are working towards a circular economy, PTFE coated fasteners are more sustainable then regular bolts due to their longer durability.

- Lower maintenance costs. Longer durability of bolts does not only result in more sustainability but also lower maintenance costs.

- Low torque friction coefficient. Due to the TEFLON top layer, torque friction is low.

- Added value. Using colored bolts into the colored frame work, valve, flange or heat exchanger gives your product extra added value.

ASTM A193 Grade B7 is a standard specification for high tensile alloy steel bolting material for use in high temperature or high-pressure service and other special purpose applications. It covers material specification for bolting used in pressure vessel service, valves, flanges and fittings.

ASTM A193 B7 stud bolts are manufactured from a chromium-molybdenum steel and are quenched and tempered (heat treated) to acheive the desired mechanical properties (strength).Alloy steel, AISI 4140/4142 quenched and tempered.

ASTM A193 B7 bolts are built to the requirements of numerous specifications and material design properties. To be more specific, ASTM A193 B7 alloy steel is a high temperature grade of A-193. B7 steel is also a chrome moly steel with a minimum tensile strength of 125ksi. Depending on your unique project requirement needs, grade B7 bolts can be used in numerous types of extreme conditions.

ASTM A193 B7 stud bolts are ideal for industrial and structural bolting application with high-temperature or high-pressure service environment. A193 B7 stud bolts is one of the most common materials for B16.5 flange bolting

Standard specification for alloy-steel and stainless steel bolting for high temperature or high pressure service and other special purpose applications. | |

| ASME B16.5 | Covers recommended stud bolt quantity, diameter, and length for use in flanged pipe fittings. |

| ASME B1.1 Class 2A | Specifies the thread form, series, class, allowance, tolerance, and desig nation for unified screw threads. UNC for 1″ diameter and smaller. UN8 (8 threads per inch) for 1-1/8″ diameter and larger. |

FULLY THREADED STUD BOLT

TYPE OF THREAD: UNC, 8 TPI

TYPE, NUT: HEAVY HEXOGONAL

DESIGN SPEC, NUT: ASME / ANSI B18.2.2 HEX NUTS

DESIGN SPEC, STUD BOLT: ASME / ANSI B18.2.1 STUD BOLT

DESIGN SPEC, THREAD: ANSI B1.1

THREAD CLASS SYMBOL, NUT: 2B

THREAD CLASS SYMBOL, STUD BOLT: 2A

Material: ASTM A193 Grade B7 stud bolt

A197 B7 stud Bolt A194 2H nuts specifications

ASTM A193 B7 Stud Bolt Chemical Composition %

| C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.37-0.49 | 0.65-1.10 | 0.15-0.35 | 0.035 | 0.04 | 0.75-1.20 | 0.15-0.25 |

A193 B7 Stud Bolt Mechanical Properties

| Diameter | Tensile Strength | Yield Strength | Elongation | Reduction | Hardness |

|---|---|---|---|---|---|

| M64 or Below | 860 Mpa | 720 Mpa | 16 | 50 | 321 HB |

| M64 to M100 | 795 Mpa | 655 Mpa | 16 | 50 | 321 HB |

| M100 to M180 | 690 Mpa | 515 Mpa | 18 | 50 | 321 HB |

A194 2H Hex Nut Chemical Components %

| C | Mn | Ph | S | Si |

|---|---|---|---|---|

| 0.40 min | 1 | 0.04 | 0.05 | 0.4 |

A194 2H Hex Nut Mechanical Properties

| Size | TemperingTempFahrenheit | Proof LoadStress, ksi | Hardness |

|---|---|---|---|

| 1/4-1 1/2 | 850 | 175 | 248-327 |

| 1 1/2-4 | 850 | 175 | 212-327 |

| (A) StudsThreaded Rod / Stud A193 B7 |