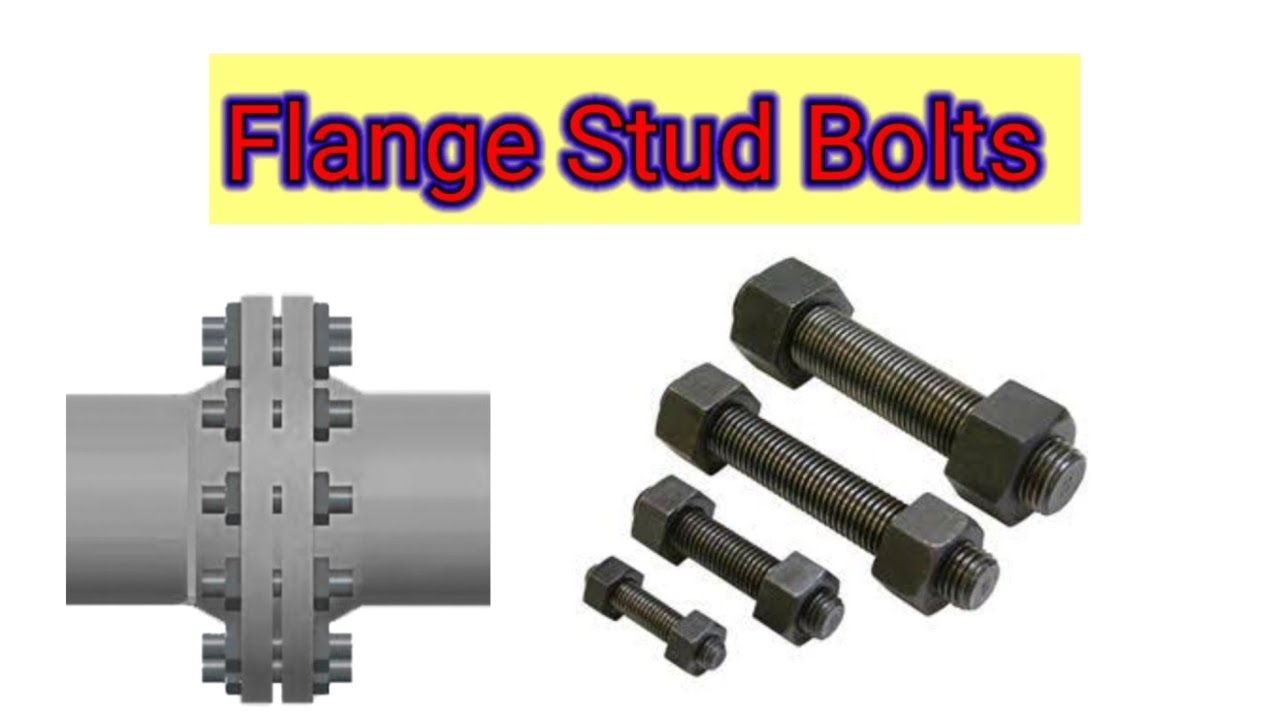

Stud Bolts are externally threaded fasteners without a head, used with 2 nuts on either side, substituting a usual “bolt & nut” assembly.

Stud bolts for flanges are the bolting material or fastener used to tighten the flange joint connection. ASME B16.5 Code

stud bolt is a mechanical fastener having external threads without a head. The external thread is either for the full length of the stud or partially threaded from each end. It uses at least two nuts, one on each side for assembly connection. Stud bolts are available in various sizes, types, and threading types

Types of Stud Bolts

Depending on the threading pattern and design, various types of stud bolts are available as listed below:

- Fully threaded stud bolt or continuous threaded stud bolt having uniform thread throughout its length.

- Tap end stud bolts having unequal threads from each end and non-threaded center.

- Double-end stud bolts having both ends threaded of equal lengths and a non-threaded center.

- Flange Stud bolts: Fully threaded stud bolts with chamfered ends specifically used for flanged connections.

- Double-end stud bolt with reduced shank: the non-threaded center part is of a reduced diameter than the actual diameter.

- Threads of Stud Bolts

- Bolts threading are defined in ASME B1.1 Unified Inch Screw Threads, (UN and UNR Thread Form). The most common thread is a symmetrical form with a V-profile. The included angle is 60°. This form is widely used in the Unified thread (UN, UNC, UNF, UNRC, UNRF) form as the ISO / metric threads.

- The advantage of a symmetrical threads is that they are easier to produce and inspect compared with non-symmetrical threads. These are typically used in general-purpose fasteners.

- Thread series cover designations of diameter/pitch combinations that are measured by the number of threads per inch (TPI) applied to a single diameter.

- Standard Thread Pitches

- Coarse thread series (UNC/UNRC) is the most widely used thread system and applied in most of the screws, bolts and nuts. Coarse threads are used for threads in low strength materials such as iron, mild steel, copper and softer alloy, aluminium, etc.. The coarse thread is also more tolerant in adverse conditions and facilitate quick assembly.

- Fine thread series (UNF/UNRF) is commonly used in precision applications and in there where require a higher tensile strength than the coarse thread series.

- 8 – Thread series (8UN) is the specified thread forming method for several ASTM standards including A193 B7, A193 B8/B8M, and A320. This series is mostly used for diameters one inch and above.

ASTM A193 B7 vs A320 L7 Stud Bolts

ASTM A193 B7 is a Bolting specification for medium-high temperature applications. It is a heat treated Chromium Molybdenum steel and is considered for applications up to 450°C (840°F).

ASTM A320 L7 has the same chemical and physical properties as B7, with additional Charpy V Notch tests taken at -101°C (-150°F) for low temperature applications.

It is typically used for the manufacture of Bolts, Fasteners, Studs and Studbolts in the Petrochemical industry. Available Drawn or Turned depending on the size in both Metric and Imperial sizes in standard and Thread Rolling Diameters. Typical stock size range 8mm to 4in Diameter in B7/L7 and 110mm to 130mm Diameter B7 only.

Mechanical Properties B7/L7

| Grade | Size | Tensile ksi, min | Yield, ksi, min | Elong, %, min | RA % min |

| B7 | Up to 2-1/2 | 125 | 105 | 16 | 50 |

| L7 | Up to 2-1/2 | 125 | 105 | 16 | 50 |

Chemical Composition B7/L7

| Element | B7 (AISI 4140) | L7 (AISI 4140) |

| Carbon | 0.37 – 0.49% | 0.37 – 0.49% |

| Manganese | 0.65 – 1.10% | 0.65 – 1.10% |

| Phosphorus, max | 0.035% | 0.035% |

| Sulfur, max | 0.040% | 0.040% |

| Silicon | 0.15 – 0.35% | 0.15 – 0.35% |

| Chromium | 0.75 – 1.20% | 0.75 – 1.20% |

| Nickel | ||

| Molybdenum | 0.15 – 0.25% | 0.15 – 0.25% |

Alloy Steel Stud Bolting Materials

ASTM A193

The ASTM A193 is heavily utilized in petroleum and chemical construction applications. The ASTM standard covers alloy steel and stainless steel bolting materials for high temperature or high pressure service. This specification includes fasteners intended for use in pressure vessels, valves, flanges, and fittings. Although, this material is often available in national coarse (UNC) thread pitches, if being used in traditional applications, threads are specified 8 threads per inch (tpi) for diameters above one inch.

ASTM 193, Grade B7

Heat treated chromium-molybdenum steel recommended for medium high temperature service. (Liquid quench -50° to 900° F, Air quench -40° to 900° F)

ASTM A193, Grade B7M

Similar to B7 studs except that the minimum yield and tensile strength requirements are reduced and the hardness controlled to 235 Brinell maximum. Recommended for use in corrosive environments. (-50° to 900° F)

ASTM A193, Grade B16

A heat treated chromium-molybdenum-vanadium steel recommended for high pressure, high temperature service. (-50° to 1100° F)

ASTM A320, Grade L7

This grade is intended for low temperature service down to minus 150° F and has a minimum Charpy impact value of 20 ft. lbs. at this temperature. (-50° to 1100° F)

ASTM A320, Grade L7M

Similar to L7 studs except that the minimum yield and tensile strength requirements are reduced and the hardness controlled to 235 Brinell maximum. This stud is recommended for use in low temperature corrosive environments. (-50° to 1100° F)

ASTM A320, Grade L43

This grade is intended for low temperature service down to minus 150° F and has a minimum Charpy impact value of 20 ft. lbs. at this temperature. Available in sizes up to a 4 inch diameter. (-150° to 1100° F)

ASTM A193, Grade B8

These Chromium-Nickel (AISI 304) austenitic steel studs are recommended for use in corrosive environments. (-325° to 1500° F)

ASTM A193, Grade B8M

These chromium-nickel molybdenum (AISI 316) austenitic steel studs are recommended for use in corrosive environments. (-325° to 1500° F)

How to select the Carbon and Alloy Steel Nuts?

ASTM A194

The ASTM A194 specification covers carbon, alloy and stainless steel nuts intended for use in high-pressure and/or high-temperature service. Unless otherwise specified, the American National Standard Heavy Hex Series (ANSI B 18.2.2) shall be used. Nuts up to and including 1in nominal size shall be UNC Series Class 2B fit. Nuts over 1in nominal size shall be either UNC Series Class 2B fit or 8 UN Series Class 2B fit. High strength ASTM A194 grade 2H nuts are common in the marketplace.

ASTM A194 Grade 2H

Suitable for use in high temperatures and high pressure conditions. Quenched & tempered.

ASTM A194 Grade 2HM

Similar to 2H nuts except this grade is recommended for use in corrosive environments.

ASTM A194 Grade 4

Heat treated molybdenum steel nuts suitable for severe temperature and pressure conditions.

ASTM A194 Grade 7

Heat treated chrome-molybdenum steel nuts suitable for extreme temperature and pressure conditions. Suitable for sub-zero service conditions and have minimum Charpy impact values in accordance with ASTM specifications.

ASTM A194 Grade 7L

Heat treated chrome-molybdenum steel nuts suitable for extreme temperature and pressure conditions. Suitable for sub-zero service conditions and have minimum Charpy impact values in accordance with ASTM specifications.

ASTM A194 Grade 7M

Similar to grade L7 nuts except this grade is recommended for use in corrosive environments.

ASTM A194 Grade 8/8M

Stainless steel nuts recommended for use in corrosive environments.