ASME B 18.31.2 Continuous Thread Stud, Double-End Stud, and Flange Bolting Stud (Stud Bolt) (Inch Series)

ASME B18.31.2 is a standard published by the American Society of Mechanical Engineers (ASME). It specifies the dimensions, tolerances, and requirements for threaded rods and studs

Continuous thread stud: studs that are threaded over their complete length.

Flange stud (stud bolt): threaded studs used primarily in applications with flanges covered by ASME B16.5, and made using ASTM bolting materials.

Double-end stud (clamping type — identical ends): studs with screw threads of the same length and configuration on each end. This type of stud serves the function of clamping two bodies together with a nut on each end.

Double-end stud (tap end type): a stud designed to be installed in a tapped hole and usually with different threaded lengths on each end. For the tap end of the studs, both regular unified threads and interference-fit threads are covered.

Double-end studs of the following body diameters are covered:

(a) Reduced diameter body

(b) Full body

The inclusion of dimensional data in this Standard is not intended to imply that all products described are stock production items. Consumers should consul t w it h suppliers concerning availability of products.

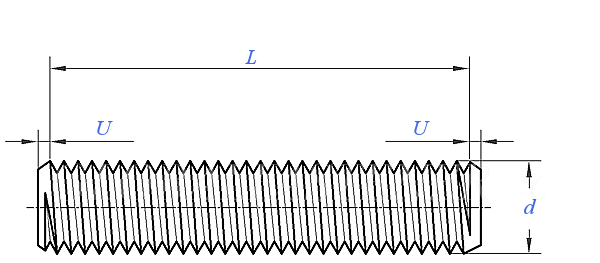

| ①,U —— Chamfered Thread Distance: Stud ends shall be chamfered from the major diameter to a diameter equal to or less than the thread root diameter. The length of the chamfered end to the first full formed thread at major diameter, as determined by the distance the chamfered end enters into a cylindrical NOT GO major diameter ring gage, shall be one to two thread pitches on each end. The ends of the stud shall be reasonably square with the axis of the stud, but the slight rim or cup resulting from manufacturing shall be permissible. The ends shall be suitable for marking. |

ASME B18.31.2 Scope:

- Covers straight-threaded rods and studs of unified (inch) series threads.

- Includes various types of studs such as double-end, tap-end, and continuous-threaded studs.

Materials:

- Details material properties and mechanical requirements for different applications.

- Typically considers carbon steel, alloy steel, stainless steel, and other materials.

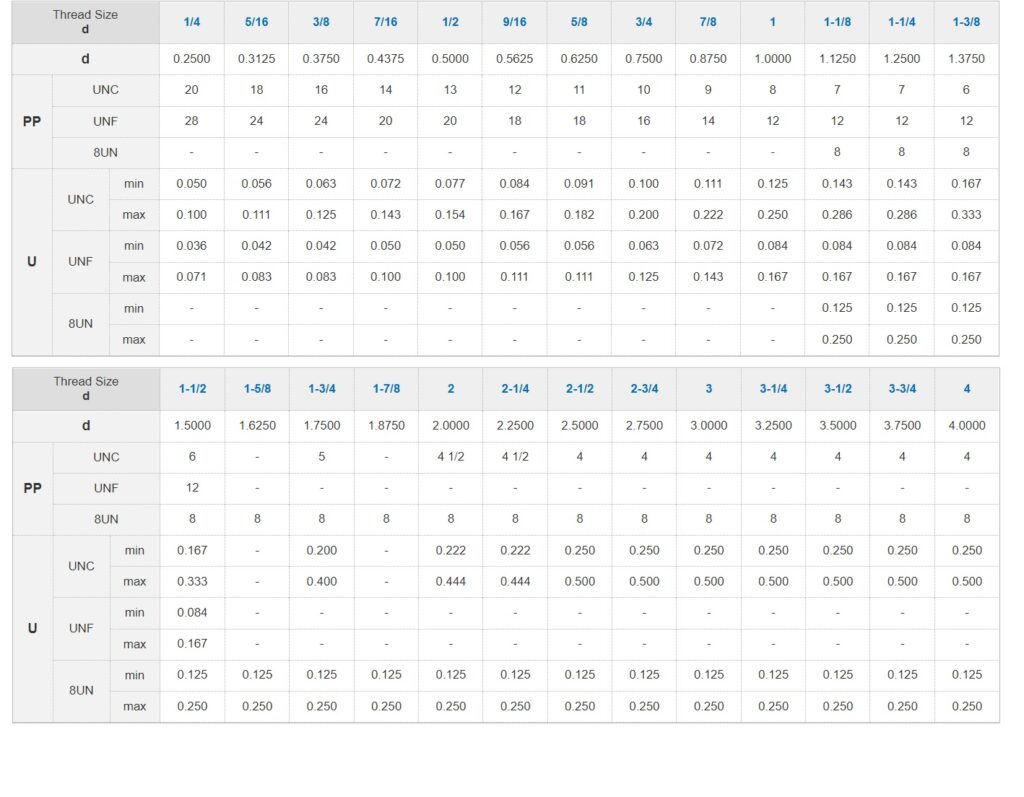

Threading:

- Specifies unified inch thread series (UNC, UNF, etc.).

- Ensures proper compatibility with nuts and tapped holes.

Dimensions and Tolerances:

- Provides precise measurements for diameter, thread pitch, and lengths.

- Tolerance limits ensure interchangeability and consistent quality.

Manufacturing and Testing:

- Addresses manufacturing standards and inspection methods.

- Includes guidelines for thread finish, straightness, and other quality parameters.

stud bolt,ASME B 18.31.2 ASTM A193-B7/B7m / A320 – L7/L7m Threaded Rod Stud