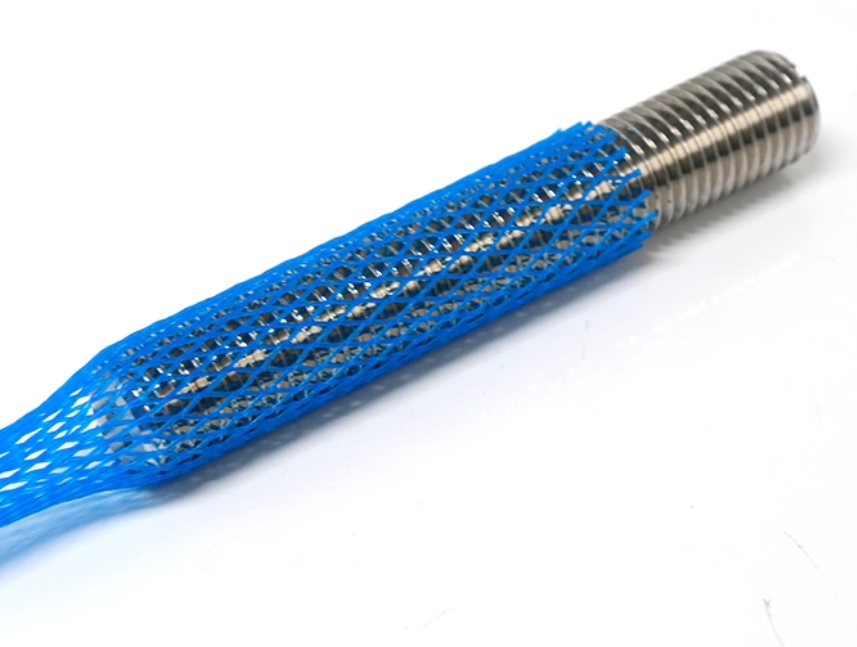

1.4539 Stud Bolt, DIN 975 904L Stainless Steel Stud Bolt

China 904L Stainless Steel Stud Bolt,1.4539 Stud Bolt manufacturer

SS904L stainless steel is a non-stabilized austenitic stainless steel with low carbon content. This high alloy stainless steel is added with copper to improve its resistance to strong reducing acids, such as sulphuric acid. The steel is also resistant to stress corrosion cracking and crevice corrosion. Grade 904L is non-magnetic, and offers excellent formability, toughness and weldability.

SS904L contains high amounts of expensive ingredients, such as molybdenum and nickel. Today, most of the applications that employ grade 904L are replaced by low-cost duplex stainless steel 2205.

The following sections describe the properties of flat rolled products in ASTM B625. The specifications may not be identical for other products such as bar, tube and pipe.

Stainless Steel 904L stud bolt Specification Format

| Specifications | ASTM A193 / A193, |

| Standard | DIN, ASTM, BS and all International Standards |

| Length | 3 mm to 200 mm |

| Washers Size | M10 – M56 3/8″ to 2 1/2″ |

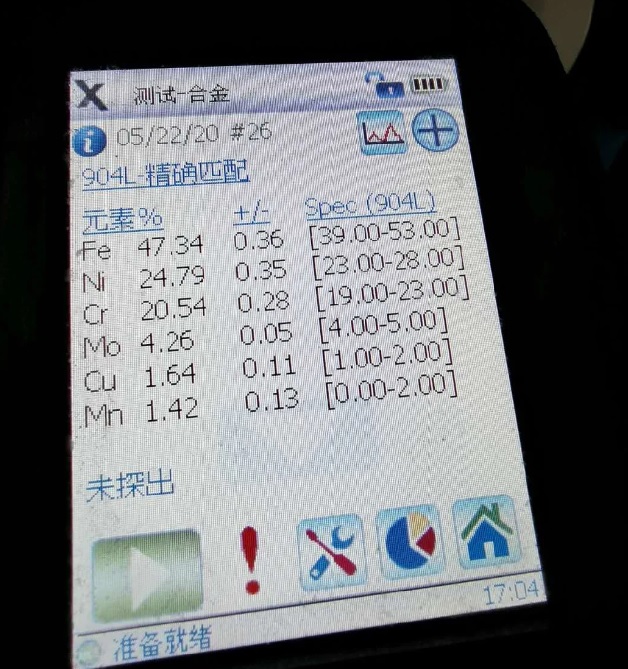

Composition of SS904L

The table below provides the compositional ranges of grade 904L stainless steels:

EQUIVALENT GRADES FOR STAINLESS STEEL 904L STUD BOLT

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

STAINLESS STEEL 904L STUD BOLT CHEMICAL COMPOSITION

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

MECHANICAL PROPERTIES OF STAINLESS STEEL 904L STUD BOLTS

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

904L stud bolts are high-performance fasteners made from austenitic stainless steel, specifically designed for extreme corrosion resistance in aggressive environments. The material, also known by its UNS designation N08904, contains high levels of chromium, nickel, molybdenum, and copper, which provide excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. These bolts are widely used in industries such as chemical processing, oil and gas, and marine applications.